Friday, March 28th, 2025 AT 6:32 PM

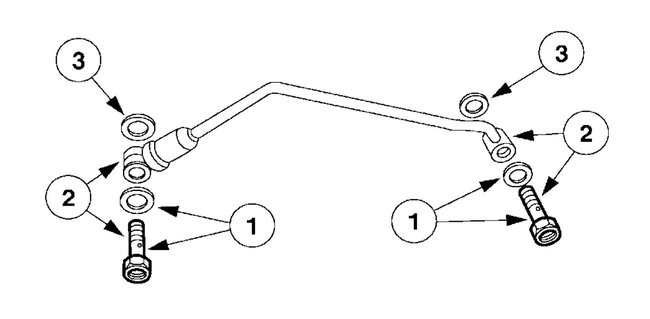

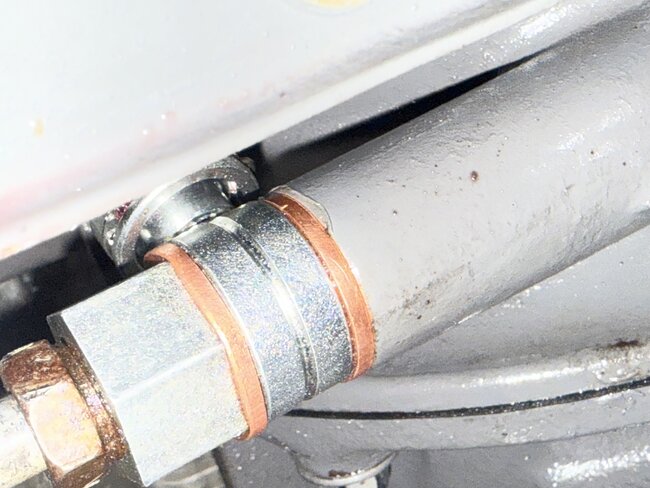

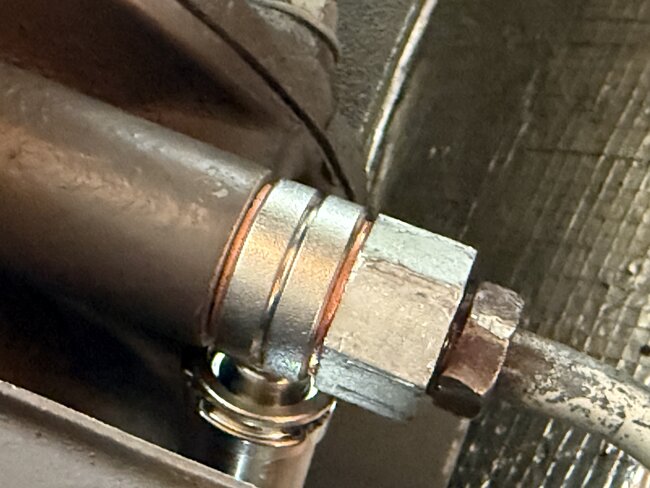

I just bought a new transmission from monster transmission. It is a 4r100. I have had a leak from day 1 from a bad transmission oil cooler bypass line and it hasn’t been drivable until today when my mechanic put a new assembly valve on the transmission. It continues to leak but not quite as bad so it was leaking from the assembly valve from monster and now not quite as bad when my mechanic replaced it. Is it possible that the port that the high-pressure part of the valve assembly goes into on the transmission is bad meaning it could have bad threads, or could it be a faulty part again that my mechanic put on it? I’ve attached a picture where it was leaking. I wiped off the fluid because I wanted to see if it was leaking new fluid or old fluid so sorry it’s not on there but leaking where the yellow arrow is pointing to in the picture. Also worth noting, monster did put a higher PSI pump in the transmission as my vehicle is a bucket truck for hauling heavy batteries for comcast as I am a contractor.