Welcome to 2CarPros.

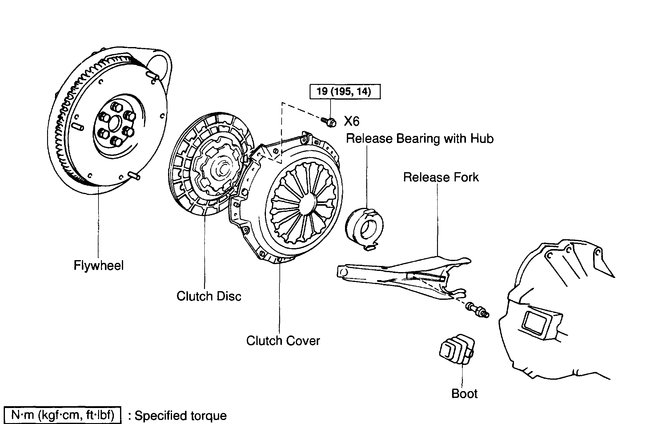

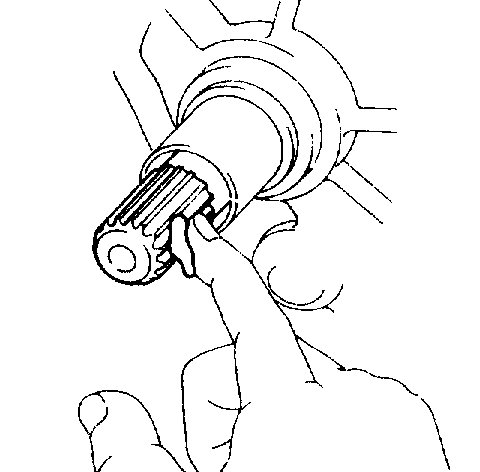

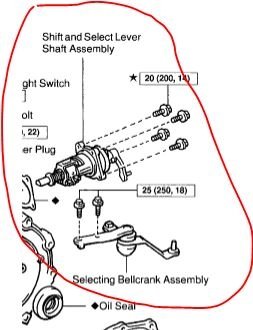

Here are the directions for removal and replacement of the clutch. The first picture is an exploded view of the system.

___________________________

COMPONENTS

REMOVAL

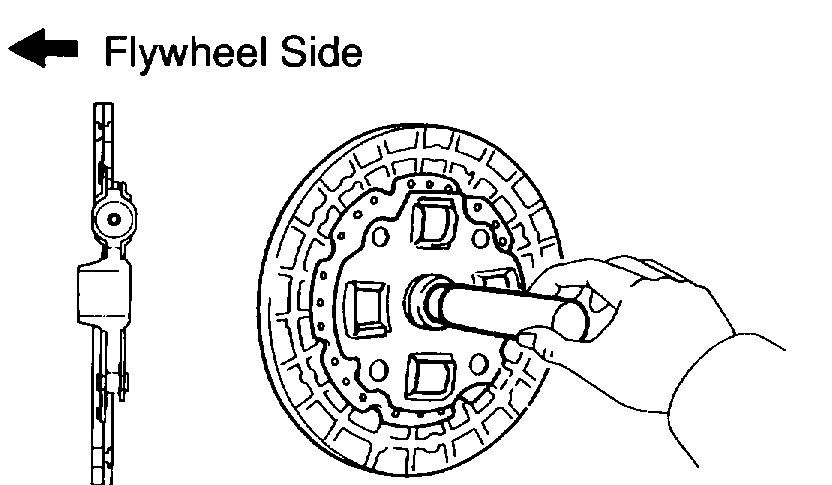

pic 1

1. REMOVE TRANSAXLE FROM ENGINE

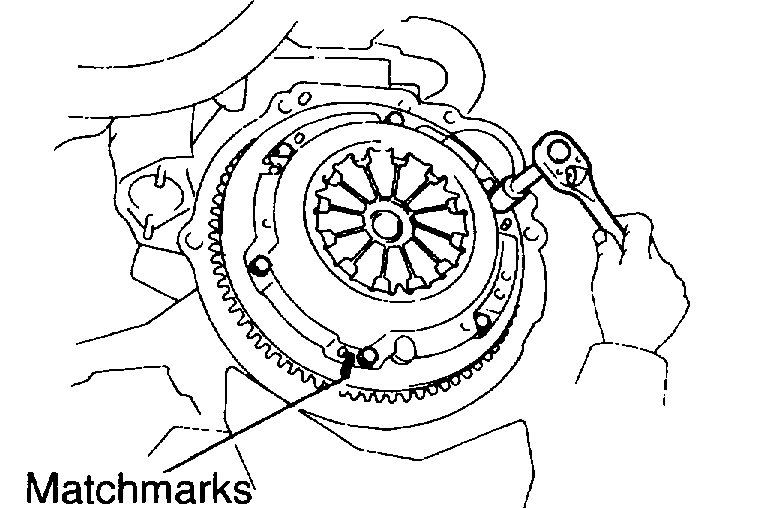

2. REMOVE CLUTCH COVER AND DISC

a. Place matchmarks on the flywheel and clutch cover.

B. Loosen each set bolt one turn at a time until spring tension is released.

C. Remove the set bolts, and pull off the clutch cover with the clutch disc.

NOTICE: Do not drop the clutch disc.

Pic 2

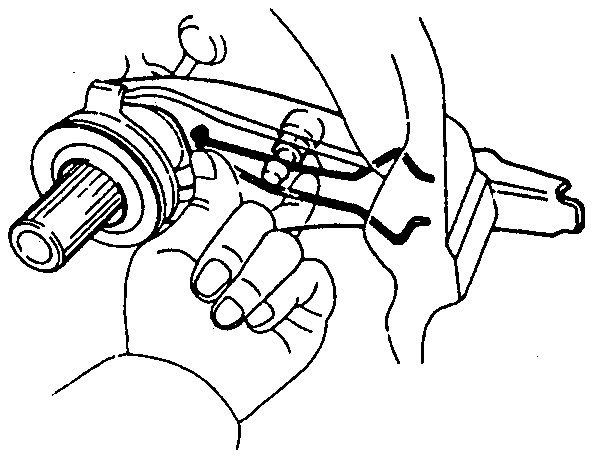

3. REMOVE RELEASE BEARING AND FORK FROM TRANSAXLE

Remove the release bearing together with the fork and then separate them.

INSPECTION

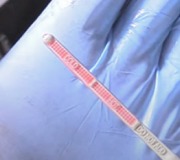

pic 3

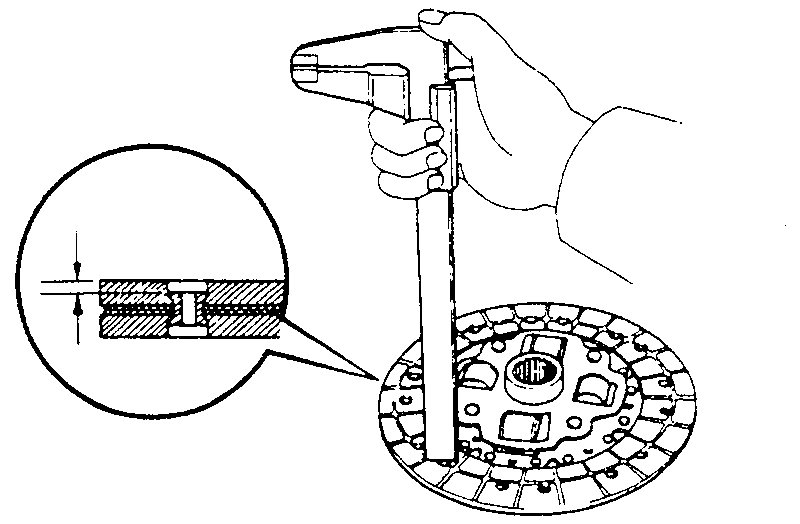

1. INSPECT CLUTCH DISC FOR WEAR OR DAMAGE

Using calipers, measure the rivet head depth.

Minimum rivet depth: 0.3 mm (0.012 inch)

If necessary, replace the clutch disc.

Pic 4

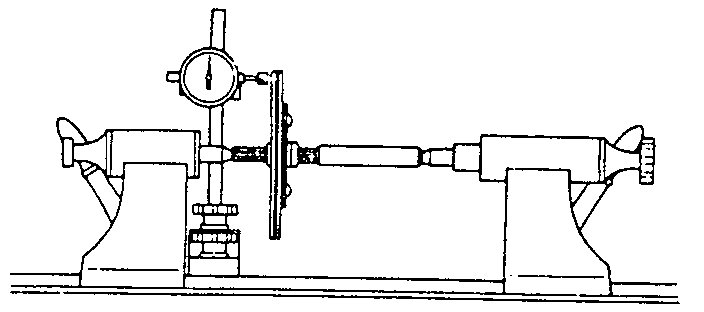

2. INSPECT CLUTCH DISC RUNOUT

Using a dial indicator, check the disc runout.

Maximum runout: 0.8 mm (0.031 inch)

If necessary, replace the clutch disc.

Pic 5

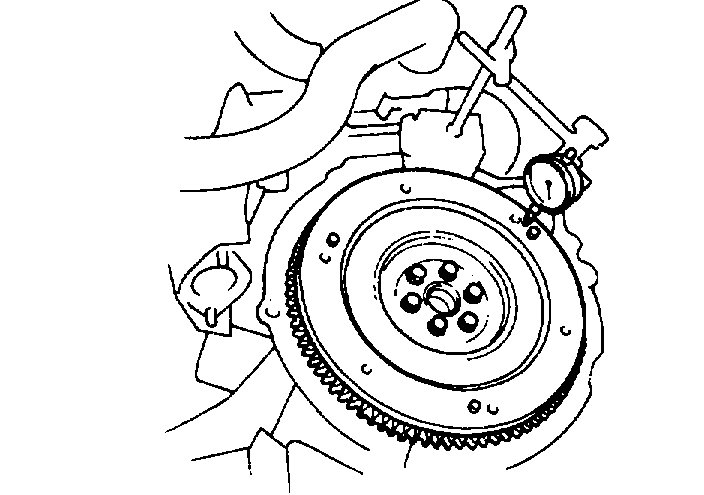

3. INSPECT FLYWHEEL RUNOUT

Using a dial indicator, check the flywheel runout.

Maximum runout: 0.1 mm (0.004 inch)

If necessary, replace the flywheel.

Pic 6

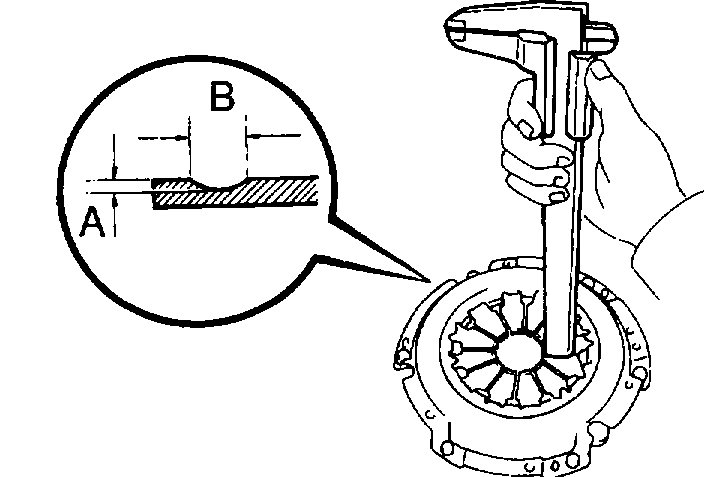

4. INSPECT DIAPHRAGM SPRING FOR WEAR

Using calipers, measure the diaphragm spring for depth and width of wear.

Maximum depth: A: 0.6 mm (0.024 inch)

Maximum width: B: 5.0 mm (0.197 inch)

If necessary, replace the clutch cover.

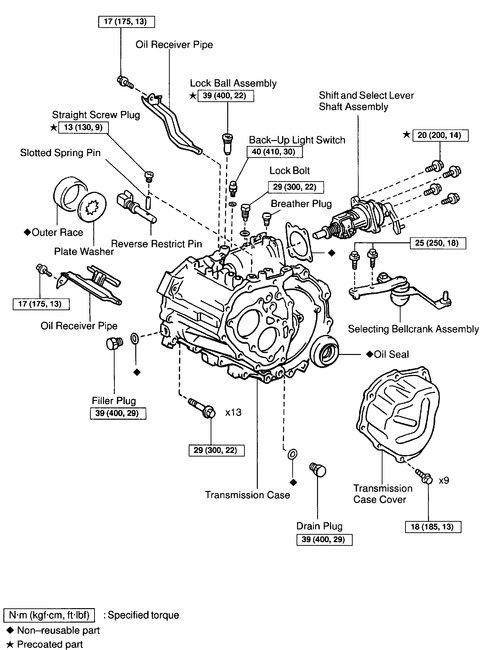

Pic 7

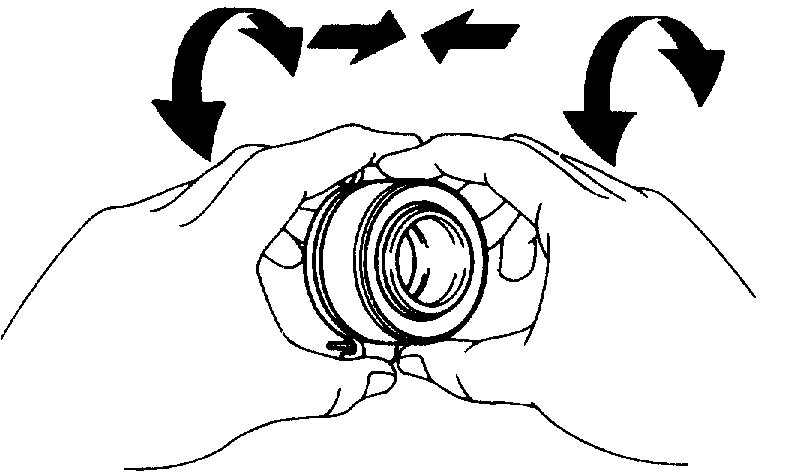

5. INSPECT RELEASE BEARING

Turn the bearing by hand while applying force in the axial direction.

HINT: The bearing is permanently lubricated and requires no cleaning or lubrication.

If necessary, replace the release bearing.

INSTALLATION

1. INSTALL CLUTCH DISC AND CLUTCH COVER ON FLYWHEEL

pic 8

a. Insert Special Service Tool (SST) in the clutch disc, and then set them.

SST 09301-00210

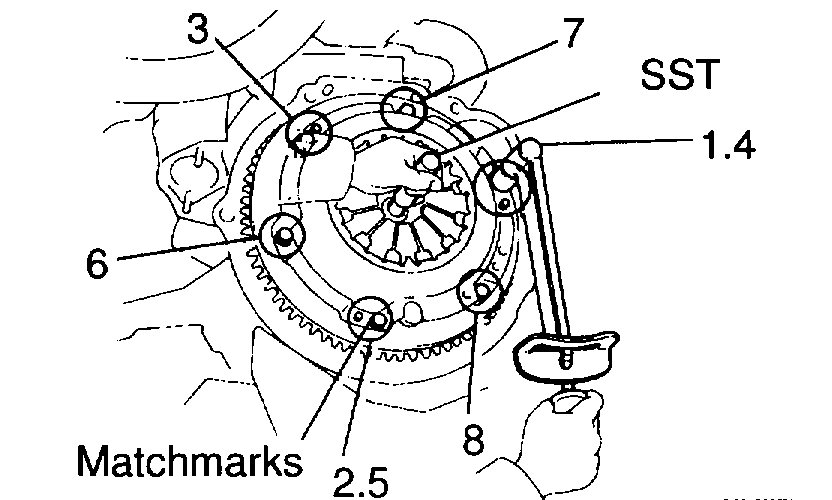

pic 9

b. Align the matchmark on the clutch cover with the one on the flywheel.

C. Torque the bolts on the clutch cover in the order shown.

Torque: 19 Nm (195 kgf-cm, 14 ft. Lbs.)

HINT: Temporarily tighten the No.1 and No.2 bolts.

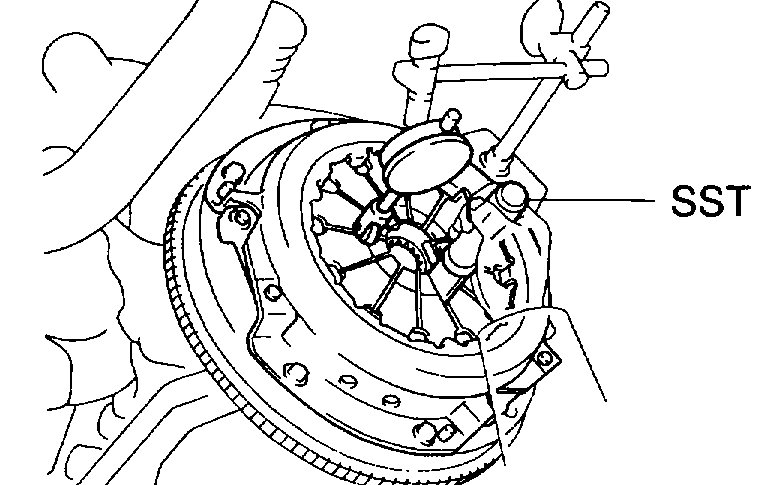

Pic 10

2. CHECK DIAPHRAGM SPRING TIP ALIGNMENT

Using a dial indicator with roller instrument, check the diaphragm spring tip alignment.

Maximum non-alignment: 0.5 mm (0.020 inch)

If alignment is not as specified, using SST, adjust the diaphragm spring tip alignment.

SST 09333-00013

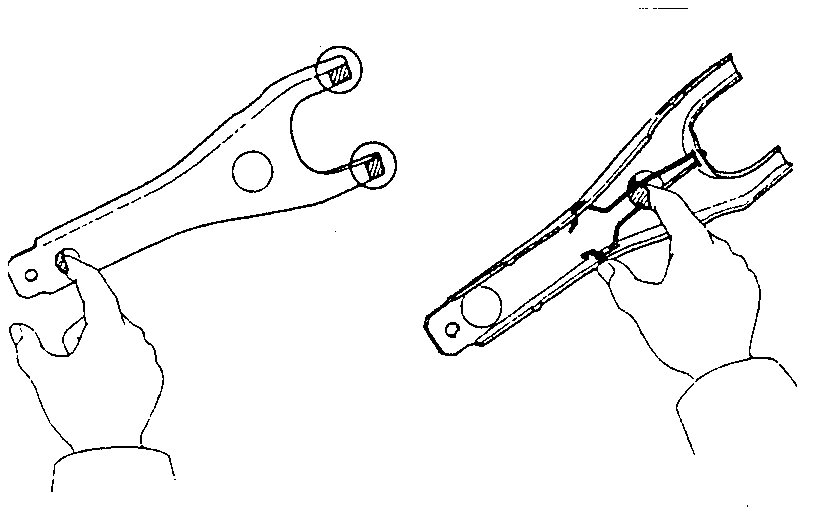

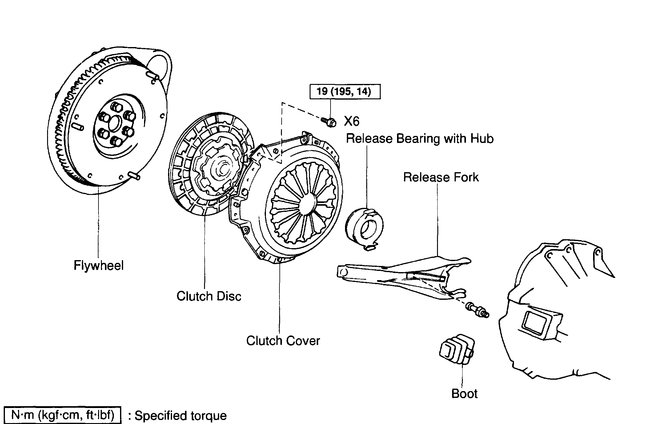

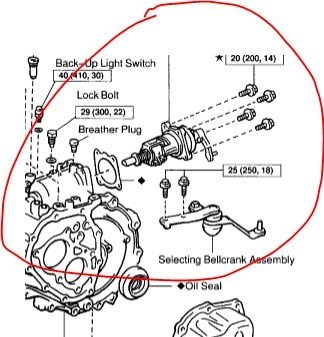

pic 11

3. APPLY MOLYBDENUM DISULPHIDE LITHIUM BASE GREASE (NLGI NO.2)

a. Apply release hub grease to these parts:

Release fork and hub contact point

Release fork and push rod contact point

Release fork pivot point

pic 12

b. Apply clutch spline grease.

Clutch disc spline

HINT: Recommended grease part number 08887-01706 (100 g).

4. INSTALL RELEASE BEARING AND FORK TO TRANSAXLE

Install the bearing to the release fork, and then install them to the transaxle.

5. INSTALL TRANSAXLE TO ENGINE

______________________________________

Let me know if this is what you needed or have other questions.

Joe

Images (Click to make bigger)

Sunday, May 19th, 2019 AT 6:44 PM