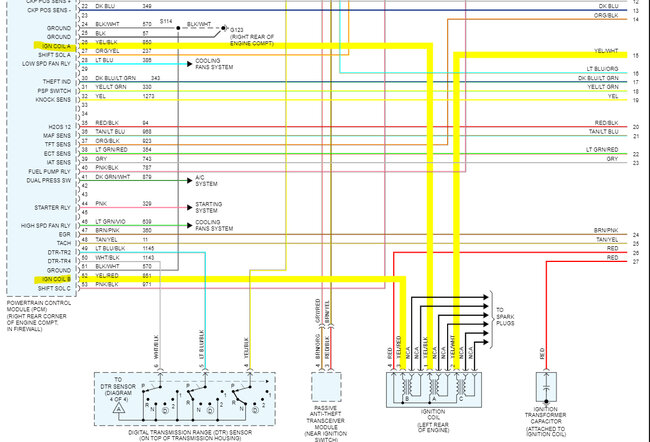

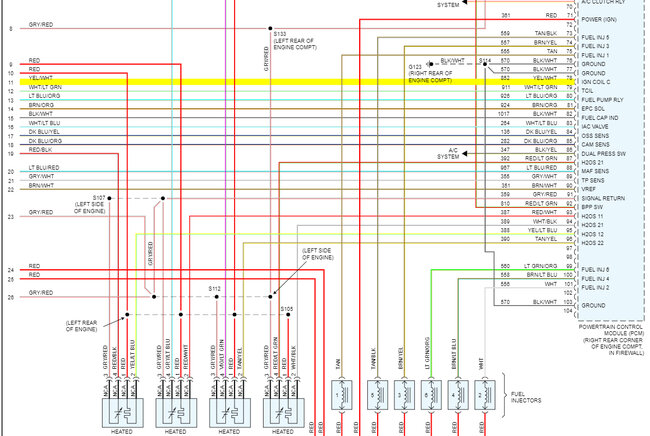

Hello, you can do a resistance check for each wire from the ignition coil pack to the PCM. I'll post the wiring diagrams, but yes you have the right idea, For the yellow/red wire at the coil will be the same color at the PCM, check from end to end, I'll post more info in a minute.

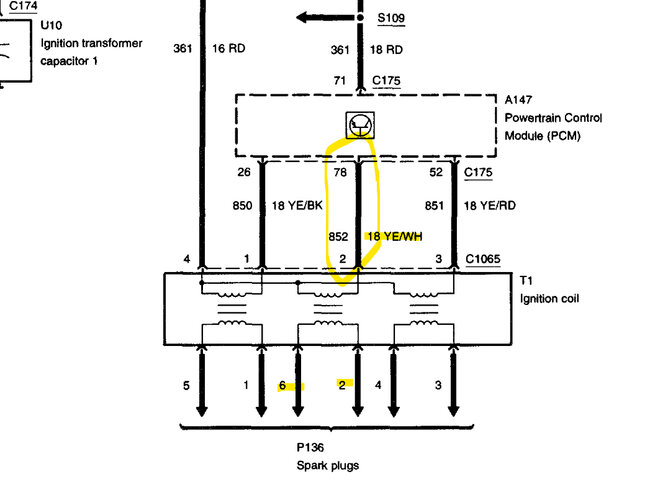

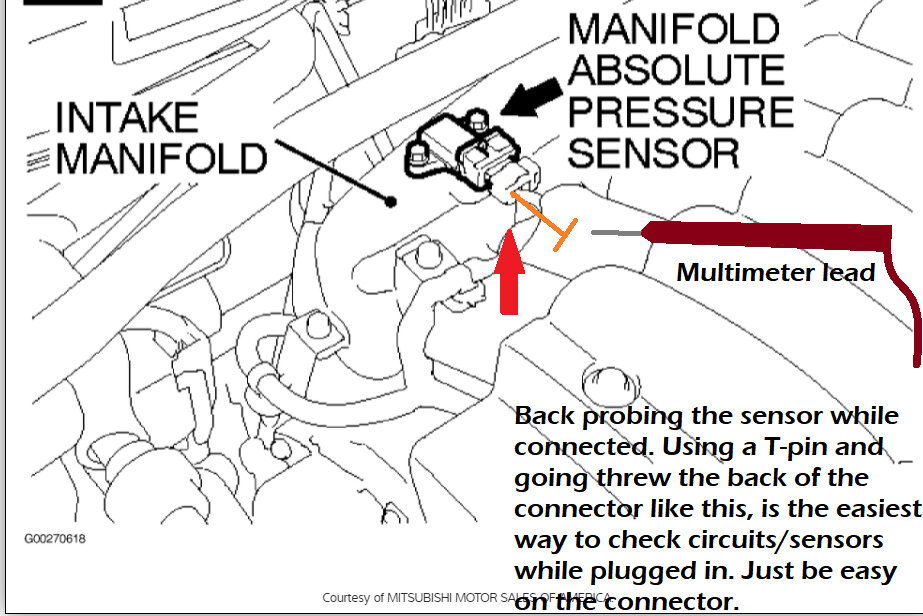

For Ignition coil B the yellow/red wire goes to PCM pin 52 it will be the same color at the PCM connector. With the PCM connector and Ignition coil pack unplugged, set the multimeter on Ohms setting and check the resistance from the coil end to the PCM end. If the resistance is below 5 ohms, check the wire at the Ignition coil to any ground location to make sure the wire is not shorted to ground anywhere. There should be no reading. Hopefully, that makes sense. After you check the wire to the PCM, let us know what you find. If there is a short to ground on that wire, you'll have to find that.

But start with just checking that wire for the coil in question. If you have any questions just ask.

Before replacing at PCM there are some other things to check.

The yellow/white wire is the wire for cylinders 2 and 6.

Be sure you have the Key Off when unplugging components.

https://www.2carpros.com/articles/how-to-use-a-voltmeter

Images (Click to make bigger)

Friday, August 18th, 2023 AT 11:46 AM