Hi,

It does sound like you have an ignition problem, It sounds like the Hall Effect is faulty, known as the (camshaft sensor). I'm attaching some diagnostic service checks on the ignition system below please read and check the complete ignition system diagnostics for faulty parts. If the ignition system is operational check the fuel pressure and engine compression. Please let us know what fixed your car or if you need more information.

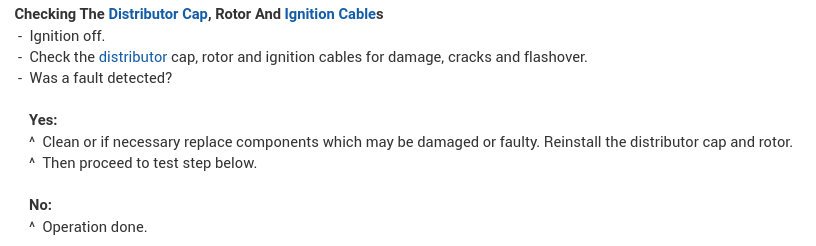

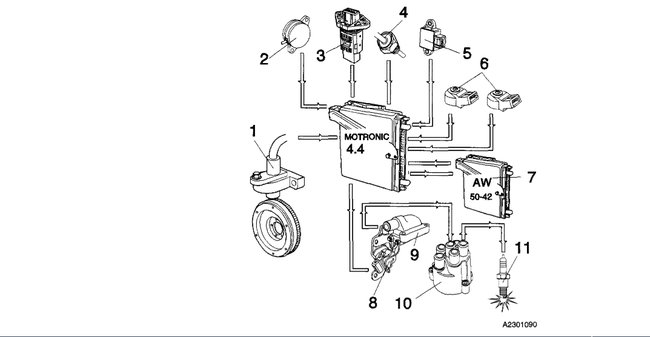

The purpose of the Camshaft Position (CMP) Sensor is to supply the Engine Control Module (ECM) with information about where the crankshaft is on the first or second revolution of a working cycle. Together with the Engine Speed (RPM) Sensor, the camshaft position (CMP) sensor also provides the engine control module (ECM) with information enabling it to identify which cylinder is knocking, if knock is detected by either of the two Knock Sensors (KS).

The Camshaft Position Sensor consists of the following components:

Trigger rotor (1)

Hall detector (2)

Cover (3)

The trigger rotor rotates at the same speed as the camshaft (4). The engine control module (ECM) supplies the Hall detector with a 12 V signal. When the opening in the rotor is opposite the hall detector the signal is grounded, the output signal is then 0 V. When the hall detector is shielded from the magnet the voltage is not affected and the output signal is 12 V.

Since the camshafts rotate at half the crankshaft speed, the output signal alternates between high and low every second crankshaft revolution, this corresponds to the working cycle in the cylinders.

The engine control module (ECM) uses the camshaft position (CMP) sensor signal to determine the cylinder in which ignition is required and also, if knock is detected, which cylinder is knocking.

The engine control module (ECM) delivers ignition in cylinders 1 and 3 when the signal is low (0 V) and in cylinders 2, 4 and 5 when the signal is high (12 V).

If the signal from the camshaft position (CMP) sensor to the engine control module (ECM) disappears, the engine cannot be started, although an engine that has started will not stop if the camshaft position (CMP) sensor stops working, as it is only used on start-up.

The camshaft position (CMP) sensor is located at the rear of the engine, on the exhaust side.

Thank you

Joe Terwilliger

Images (Click to make bigger)

Monday, December 30th, 2019 AT 7:22 PM