We don't want to throw random parts at a problem. That's the most costly and least effective way to diagnose a problem. The far better alternative is to look on eBay for a Chrysler DRB2 scanner. They're often available for a couple of hundred dollars, but if you've never used a scanner, you'll be amazed at what you've been missing.

There are a few things to be aware of. First, these need a plug-in cartridge that covers the vehicle you're working on. There were dozens of them, including for the Mitsubishi-built models. It isn't practical to try to find every cartridge that was available. Instead, toward the end of their reign, Chrysler came out with "Super cartridges" that covered all models. The first one I recall was in 1993. It had a blue label to match the color of the service manual covers for that year. Next was one with a yellow label for '94 models. That is the Super cartridge to look for. Nothing changed for the '95 models so you use the '94 cartridge for every Chrysler product from '95 back to '83.

Once you have the scanner and an appropriate cartridge, there are two cables. The main one has a square plug with a corner notched out, and six terminals. That's used for the Engine Computer, which is what we need now. The other cable has a smaller rectangular plug, also with six terminals. It plugs into a blue connector behind the inside fuse box cover left of the driver's knees, or on the right side of the center console, under the dash. That one's for the ABS, Air bag, and, as I recall, the Transmission Computer when you have one. We don't need that cable for this problem.

The problem with the DRB2 is they only work on '83 through '95 models. I also have a "Monitor 4000". That's the aftermarket version, but it looks very much like the DRB2, uses its own cartridges, and was built by the same company that built the DRB2 for Chrysler. You can find these on eBay too. There's a lot of other brands of older scanners, but these are the ones I'm familiar with. The advantage of the Monitor 4000 is one cartridge covers all GM, Ford, and Chrysler models up through the year the cartridge was made. Mine only goes to '92 or '93 models. I also have a separate anti-lock brake systems cartridge, but I never plugged it in to try it. The advantage of the DRB2 is it does everything the engineers wanted us to be able to do. The Monitor 4000 doesn't do quite as much, but it does it on more car brands.

If you want to step up and don't care about cost, look for a Chrysler DRB3 on eBay. The entire kits used to cost $6200.00 through the manufacturer's web site, but I paid close to half of that by going through the parts department at the dealership I used to work for. Today they still bring around $2000.00. Depending on the year they were made, they work on models back to '96 or to '98 directly, and up to the last years they covered. The first models to be obsolete was the 2004 Dakota / Durango. The last models were some 2008 Jeeps. They could use an entirely different type of plug-in cartridge that would let you work on older models. Depending on the cartridge, one let it work on models back to '94, and it let you do emissions-related stuff on all car brands sold in the U.S. Starting with '96 models. A different cartridge let you work on '83 through '93 models. That's the one you would need for your truck. There's three cables for the DRB3. The main one is the trapezoidal one used in all cars now starting with '96 models. The other two have the same connectors as those two for the DRB2. Because of their ability to work on emission system problems on all car brands, a lot of independent repair shops bought them. Since they're long obsolete now, many of those shop owners are happy to sell them so they can invest in something newer. That's why a lot of these show up on eBay.

Next would be a higher-end aftermarket scanner. My friend and I each have a Snapon Solus Edge, but mine is only updated through 2018 models. The disadvantage of these is the cost of annual updates is very high; so high, in fact, you're better off just buying a new model every five to six years. The advantage for you and me is they lose their value to repair shops when they get a few years out of date. As long as mine works on my two 2014 models, that's all I need, but it lowers their value, so you can find these as low as around $700.00. No cartridges needed or used with this model, but for anything older than a '96 model, you need a different cable and the correct connector for the vehicle you're working on. Those connectors, (Snapon calls them "adapters"), are very reasonable on eBay. I bought over a dozen cheap ones just to have, even though I'll likely never use them.

I just ordered a new Autel scanner last week based on a glowing review by one of our other experts. Cost was less than $1300.00 and it comes will all kinds of connectors to fit just about any brand of car and light truck. I'll know more about that one soon.

The point of this story is we're spinning our wheels from not knowing what your Engine Computer is seeing and responding to. This is like a new doctor who hasn't invested in a stethoscope yet. We need to address the coolant temperature sensor problem yet, but that can wait until we solve the running problem.

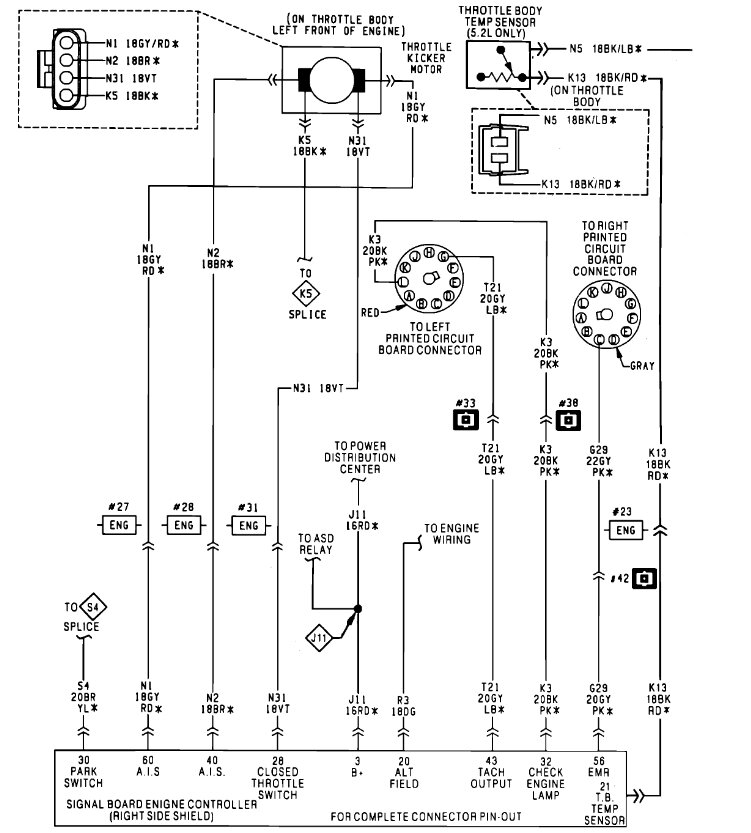

To address your comment about the last two sensors, the throttle position sensor tells the Engine Computer five things. When you're at closed throttle, (idle), when you're at wide-open-throttle, (clear flood mode), throttle position, direction of change, and rate of change. This sensor is the least important one for proper engine operation. In a very rare instance, it can cause a crank / no-start, as it did on my '94 Voyager, but that was so unusual, I know I'll never see that again. Normally, at most, it will cause a very slight hesitation when you want to accelerate. You can monitor the voltage on the signal wire with a digital voltmeter. This sensor has mechanical stops that limit how far they can read. The numbers can vary a lot, but for training and explanation purposes, we typically use the range of 0.5 volts at closed throttle, to 4.5 volts at wide-open throttle. (I commonly find 4.2 volts to be the highest they'll read). The important point is anything outside that range is what gets detected by the computer as a defect, and triggers a diagnostic fault code.

When you watch that signal voltage sweep up and down as you work the accelerator pedal, digital voltmeters update their readings rather slowly, as in a few times per second. You can watch the same voltage on the scanner. For some years now there are very inexpensive units on the market that are called "scanners", but while they can show you much of the same data, they update painfully slowly, as in once every four to five seconds. One thing we always want to watch for is a "dropout" where the voltage is rising smoothly, then suddenly drops to 0.0 or 5.0 volts for just an instant. You'll never see that with these inexpensive units. You are unlikely to see that with a digital voltmeter. And there's a good chance you won't catch it with a more expensive scanner. The Engine Computer is the only thing that's fast enough to catch many of these dropouts. It will set an appropriate fault code that will tell us where to start the diagnosis. Without the scanner to show you what the computer is responding to, you're stuck with guesses and trial and error methods.

By the way, my TPS did cause that crank / no-start, but for the previous owner, it caused a very intermittent failure of the transmission to upshift normally. It was not in "limp" mode that keeps it in second gear. It was in the shop three times for that but no one could make it act up, and there were no fault codes set to tell anyone what was happening. I figured out it was the cause of both problems once I made it back home and connected the DRB3. Within a minute I saw the readings from the TPS were well within the acceptable range of 0.5 to 4.5 volts, so no fault code was set, but the readings were wildly wrong. The TPS would stick at a higher reading which told the computer I was requesting clear flood mode. In response, the computer stopped firing the injectors, hence the crank / no-start. As soon as I pressed the accelerator pedal all the way to the floor, then released it, the TPS signal voltage followed it back down to 0.5 volts like it was supposed to, then the engine would start right up. There's no way I or anyone else would ever have figured that out without a scanner. The Transmission Computer interpreted that too-high TPS voltage as I had it floored to take off from the stop light, so it was delaying the up-shifts to a higher road speed like it was supposed to do, except I wasn't really going that fast.

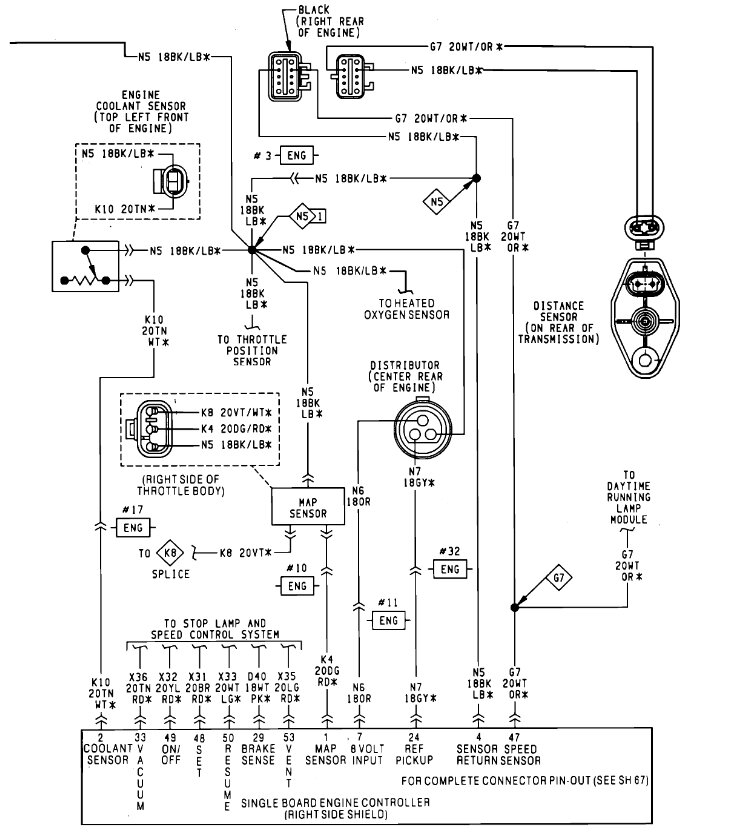

The MAP sensor IS very important for fuel metering calculations. On all other car brands, a mass air flow sensor is used to measure the weight of the incoming air, then the computer figures out how much fuel to request to go with that air. According to some national instructors, "Chrysler was the only manufacturer that could make an engine run right without a mass air flow sensor". The MAP sensor was what Chrysler used for many years. It simply measures intake manifold vacuum to calculate engine load, but right after the ignition switch is turned on, and before the engine starts running, it also measures barometric pressure. This sensor works very differently than the TPS, and it has circuitry inside, but the range of signal voltages it puts out is again, 0.5 to 4.5 volts. Besides electrical problems with this sensor, the computer can also detect pneumatic problems with it. We were taught they do not use this sensor to measure engine speed, but they could if they wanted to because they're so sensitive, they see every tiny pulse of vacuum change each time an intake valve opens and a piston takes a gulp of air. If we were to see the MAP sensor putting out 2.3 volts, for example, and we tried to replicate that with an adjustable power supply, the Engine Computer would set this pneumatic-related fault code because it didn't see the tiny ripple in the voltage readings. That could correspond to a kinked vacuum hose going to the sensor that prevented it from responding fast enough. There was a real problem on the older K-cars where there was a droop in one section of that vacuum hose, and fuel vapors could condense there and dampen the voltage fluctuations to the point the computer would set the MAP pneumatic code.

To add to the misery, GM developed this MAP sensor and had a huge problem with them, ... So they sold them to Chrysler. That's the way the story went in one of the classes I attended. Of course Chrysler had all kinds of failures too, including on my '88 Grand Caravan. There's more to this story, but once that sensor was redesigned by the early '90s, failures were very uncommon. It's very unlikely one of those of the original design is still around. Problems today are more likely to be caused by a dry-rotted vacuum hose going to that sensor. If you want to try a different one, since the failures now are so low, I'd grab one from a vehicle in a salvage yard. The same part was used over many models through many years. Since you don't have a fault code set related to this sensor, it really is not a good suspect.

If you have an engine that stalls after it gets warm, especially if it occurs right after stopping a hot engine, as in when stopping for gas, the first thing to do is check for spark. If that's missing, about 95 percent of the time you'll be missing injector pulses and fuel pump too. The fuel pump will still run for that initial one second, so pressure readings will appear to be normal.

As a final point of interest, I got called to my friend's shop today to help with a 2001 Ram 3500 that ran fine the last time it was run two months ago, but now is a crank / no-start. Everything appeared to be working, but it did try to run when we sprayed gas into the intake. Turned out to be sugar in the tank. We ran the fuel pump to empty the tank, then five gallons of new gas had it running in less than a minute. Appears to have no clogged injectors or filters, but there's a lot of steam from the water we used to put out the two fires. Fortunately, neither of us lost any eyebrows.

Will wait to hear what you find next, then we'll see what else we can come up with.

Monday, September 11th, 2023 AT 9:54 PM