Dandy news. Now for the clinker. I spent many hours putting this next reply together so I'm going to post it, mostly for the benefit of others researching this topic. You won't offend me if you ignore it. It's here for your reading pleasure:

It's important to use correct terminology in the classroom. As such, we use "AC generator". This was developed by Chrysler and first used in 1960 models. They copyrighted the term, "alternator". Regardless, everyone knows what is meant when we refer to "alternator". GM had their version in 1964. Ford had theirs in 1965 or '66.

The original DC generators developed direct current. That is necessary to store energy in the battery. While output voltage, and therefore, output current was still regulated, only two conditions were possible. The generator could develop up to its full rated current, or when defective, it would develop no current. There was no in-between.

AC generators develop alternating current. There's no way to store that unless it is "rectified" and turned into direct current. Home battery chargers do the same thing, although much less efficiently. All AC generators develop three-phase output which is very efficient and stable. "Diodes" are what causes the change to direct current. Those are one-way valves for electrical current flow. There are always a minimum of six diodes. They're shared at different times by each of the three phases. Those correspond to three groups of coils of wire in the "stator". That's the fixed wires around the outside of the generator where the output current it taken.

When the system is working properly, all generators will develop only as much current as the electrical system needs plus what's needed to keep the battery charged, and no more. The only time the full output is developed is during the few seconds it takes to perform the professional output current load test. A common generator for an '85 GM model was a 65-amp generator. I'll use that for this story. It doesn't matter if your car has a 65-amp, a 95-amp, or a 150-amp unit, if the entire electrical system needs 28 amps, for example, that is all that will be developed.

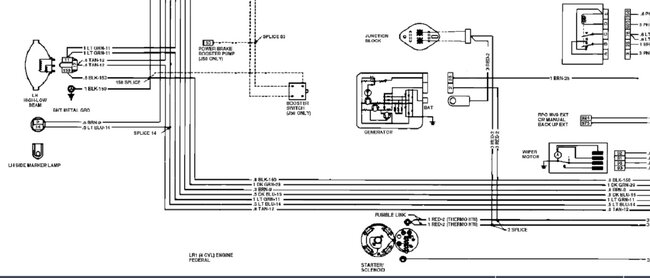

Unlike with DC generators that have only two modes, working properly or not working at all, AC generators have another failure mode. That occurs when one of the six diodes fails. Most commonly one will short, (acts like a piece of wire), then it will overheat and burn open. Those six diodes are in two groups of three. If one were to short in each group, there would be a dead short across the battery. It's those diodes that block current from instantly discharging the battery when the engine is off. If two of them did short but not burn open, the excessive current draining the battery will burn the fuse link wire open. When you do find that fuse link blown, it was due to those diodes or from a metal tool touching the output stud on the generator and something metal on the engine at the same time. Fuse links are a slow-blow device, so it takes a little time for them to burn open. Having two shorted diodes is very uncommon, so replacing fuse link wires is also uncommon.

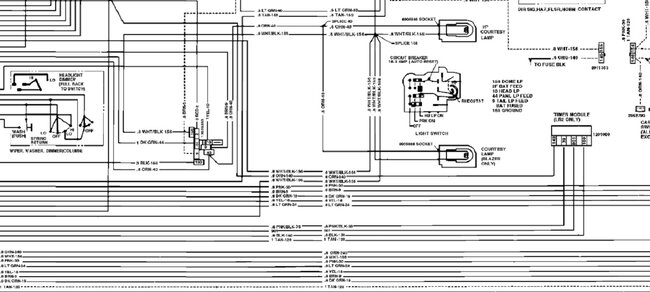

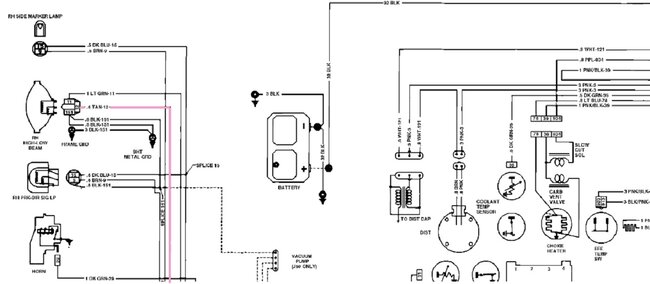

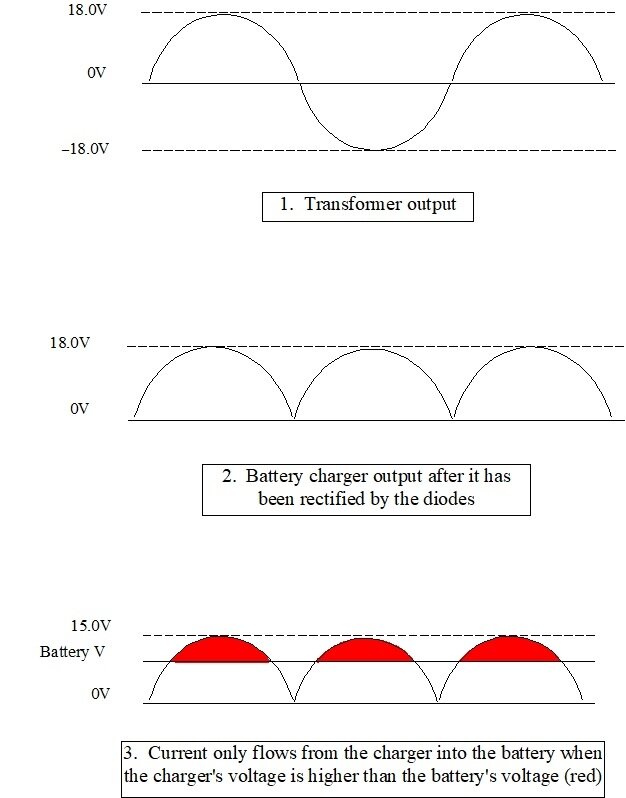

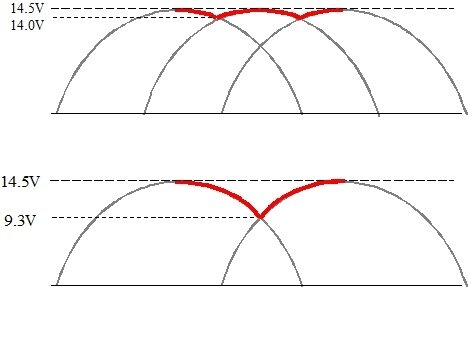

To do justice to this explanation, it's easier to start with battery chargers. Here again, if you don't follow this, or if it becomes too tedious or confusing, we'll still get through this. Alternating current in your house wiring changes direction back and forth 60 times per second, (60 cycles per second, or 60 hertz). Even this will become important later. When graphed, the waveform looks like the first one in the first image below. After it passes through a transformer, we get the same waveform, but a lower voltage version. Plus and minus 18.0 volts is shown. That would be typical for a larger wheel-type charger set to a medium charge rate. Diodes in the charger redirect current during the negative half of the cycle to positive current flow. The waveform, and current flow, look like the second waveform. Output voltage, (pressure), goes from 0 volts to 18 volts in this example.

A good, but fully-discharged battery will measure close to 12.2 volts. At any time the voltage coming out of the charger is less than 12.2 volts, no current will flow. Think of a piston-type water pump pushing water into a storage tank. No water will flow into the tank until the pump's pressure pulses higher than the pressure in the tank. This means current flowing into the battery pulses on and off 120 times per second. That pulsing physically causes the plates in the battery to vibrate.

The lead in batteries flakes off the plates over time. This can't be avoided, and battery manufacturers know how quickly this will happen. They offer warranties to capitalize on that, and make them as long as possible. That lead flaking occurs faster and faster as the battery gets older. When the battery charger makes them vibrate, the flaking speeds up. That material builds up in the bottom of the case. When it builds high enough, it shorts the plates in that cell, then the battery must be replaced.

When charging at a high charger setting, the voltage in the second waveform might go to 20.0 volts instead of 18.0 volts. During the times current flows, (waveform 3), it pulses harder and vibrates the plates a lot harder. That greatly increases how much lead flakes off. This is why we always recommend charging at the slowest rate the charger offers, especially with older batteries. Two hours is usually sufficient to reach near a full charge.

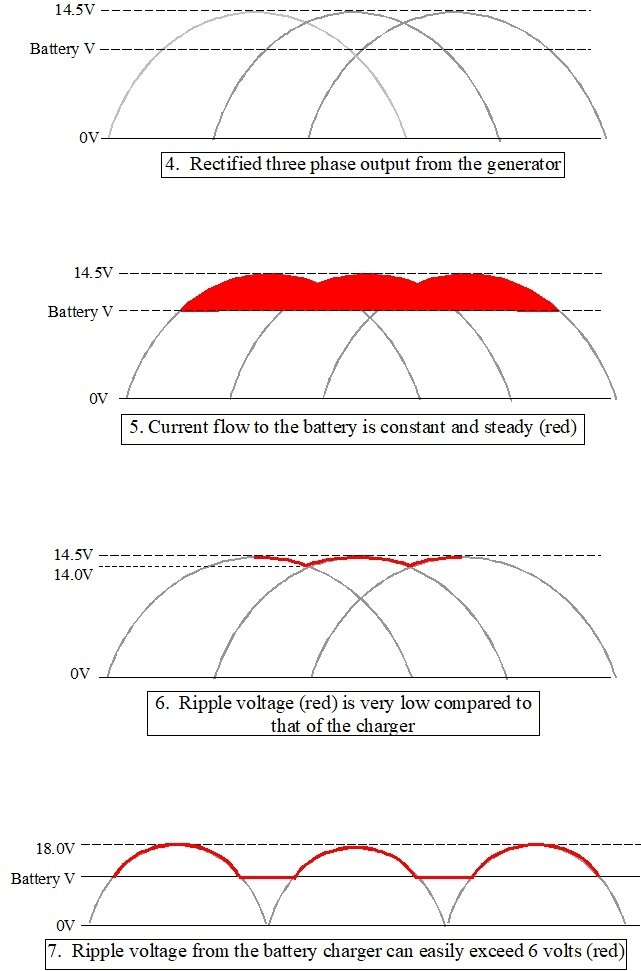

The second image shows generator output. Waveform # 4 shows the three-phase output, already rectified. Where the voltage from the battery charger goes from 0.0 volts to some maximum, here the voltage never goes to 0.0 volts, or even below battery voltage. There is always one phase contributing some current, and two are contributing at times. That's shown with the red area at the top of the fifth waveform.

We're finally coming to that third method of AC generator failure. Since the three output voltages are rising and falling, and they're overlapping, the voltage leaving the output stud looks like the red line at the top of the sixth waveform. This is called, "ripple voltage". By comparison, ripple voltage from the battery charger is shown in the seventh waveform. To be accurate, it would actually be 18.0 volts, but the battery itself is limiting how low the voltage will go.

We can measure ripple voltage, but not accurately. When you measure charging voltage with the engine running, that is done on the "DC Volts" scale on the meter, and the battery disregards ripple voltage by smoothing and averaging out system voltage. On the "AC Volts" scale, the meter measures the change in voltage over a short period of time and disregards, or blocks out, any DC voltage. In the sixth waveform, ripple voltage is 0.5 volts, (14.5 � 14.0 volts).

The voltmeter is what prevents us from measuring ripple voltage accurately. There's at least a dozen individual coils of wire around the stationary stator assembly. Each one gets some voltage induced into it as the north � south magnetic fields from the field coil rotates past them. That creates at least 24 voltage pulses per revolution. Multiply that by three phases, then there's 72 pulses per revolution. Next, the crankshaft pulley is roughly six times larger in circumference than the pulley on the generator. The generator spins six times faster than engine speed, so now there's at least 432 voltage pulses per crankshaft revolution. Engines typically idle at around 800 rpm, or 13 revolutions per second. That means ripple voltage will be at a frequency of almost 5,616 hertz.

Voltmeters can only be accurate at one frequency on the "AC Volts" scale. They are designed to be accurate at 60 hertz which is found in home wiring. At any other frequency, the meter will reduce how well it responds. It may see a voltage to measure, but the value will drop off as the frequency gets further from 60 hertz. AC voltmeters used by the military can be accurate up to 400 hertz, but even those can't measure ripple voltage accurately.

When it comes to the professional charging system tests, the testers want us to put the generators at a speed where they're most efficient. That's at 2,000 rpm. Automatic testers know when that is reached by measuring the ripple voltage frequency. It will be near 14,256 hertz now. There are a few tester models that are designed to be accurate around that frequency. They can measure ripple voltage as an actual voltage and include that on a paper printout. Most testers just display ripple voltage on a relative bar chart with six or seven LED lights. The number of lights lit up or flickering indicates whether ripple voltage is "high" or "low". No exact voltage is given.

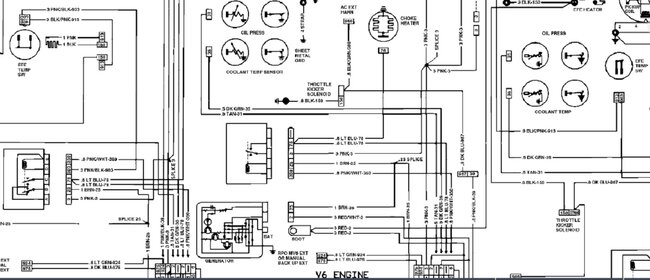

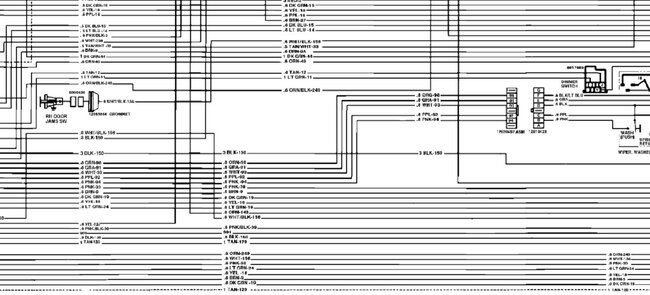

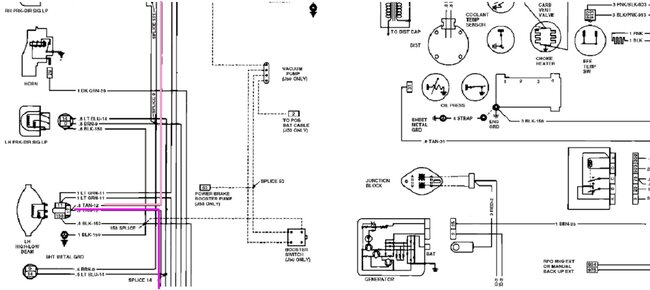

Enough suspense. The third method of operation with AC generators is when there's a failure of one diode. One of the three phases is lost, as shown in the lower waveform in the third image. Ripple voltage here is 5.2 volts, (14.5 � 9.3 volts), but it would simply show up as "high" on the tester.

The high ripple voltage verifies the other symptom of this failure. That is the maximum current the generator will be able to develop is exactly one third of its rated current. That's roughly 22 amps from your 65-amp unit. Up to three of those amps goes right back to run the field coil, so what you're left with is barely enough to run two headlights, the tail lights, ignition system, and an electric fuel pump. There's nothing left over to run the heater fan or to keep the battery charged. The battery has to make up any difference until it slowly runs down over days or weeks.

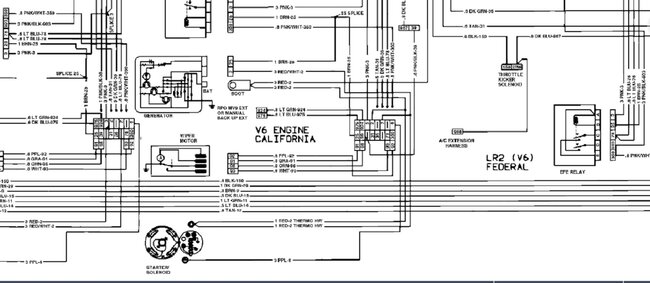

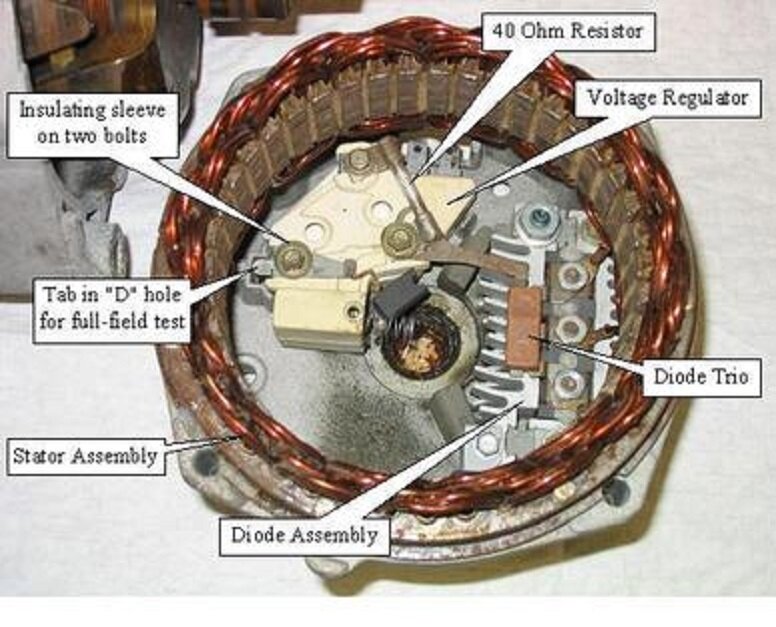

So a diode failure is the second type of failure for an AC generator after a total failure to charge, but there is a third failure method that only applies to this GM generator. Remember the story of how this generator can be used as a single-wire system for a hot rod? There still has to be a current source for the field coil and to run the built-in voltage regulator. That is done internally with a "diode trio". They tap off a tiny fraction of current from each of the three stator windings, rectify that through the very small diodes in the diode trio, and use that to supply the field coil, and it is used to go back out on your brown wire to turn off the "Battery" light.

A failure of one of the diodes in the diode trio is somewhat common. Very often owners don't notice the only clue, but mechanics do when they drive the vehicle into the shop for other services. That is the "Battery" light will be lit very dimly. When the phase currently producing current is the one with the bad diode in the diode trio, no current is supplied to the field coil, and no voltage is applied to the warning bulb. The bulb only turns on one third of the time, so it is dim. Current to the field coil drops out but the other two phases will still be contributing a little, so the electromagnetic field becomes weaker. That translates into less current being developed in the stator coil. The clue here, besides the dim light, is the maximum current that can be developed is less than the design value, but considerably more than the one third in the previous failure. You might be able to get as much as 45 to 50 amps under the full-load output current test.

There's one more observation, but you're unlikely to ever notice it. When building "bugged cars" for my students to diagnose, one was a failed diode in the diode trio that could be switched in or out. In the failed mode, charging voltage actually jumped up about 0.3 volts. That is due to how the voltage regulator responds. In this design, they see the momentary voltage dropout from the diode trio. The voltage regulator sees that and increases current flow through the field coil to make a stronger magnetic field. That causes higher voltage to be developed in the stator. Once the regulator sees the return of voltage from the diode trio, it takes longer to respond to that, so it keeps the field current at that higher value. Voltage regulators in other designs from other manufacturers can respond differently. They can cause output voltage to drop, even to the point of producing no output current.

Back in the 1970s through the '90s, it was common to repair these generators. Voltage regulators, diode trios, and worn brushes were common failures.

I have to stop here and point out we normally do not repair starters and generators today except for ourselves. For customer vehicles, we don't want to risk angering someone if the repair goes sour. It is also not a good value when we have to charge for the additional time. It's less expensive to just replace the assembly with one with a warranty. We can save money for ourselves by replacing just the defective parts when time isn't a consideration, but then we have only ourselves to blame if we have to do the job a second time.

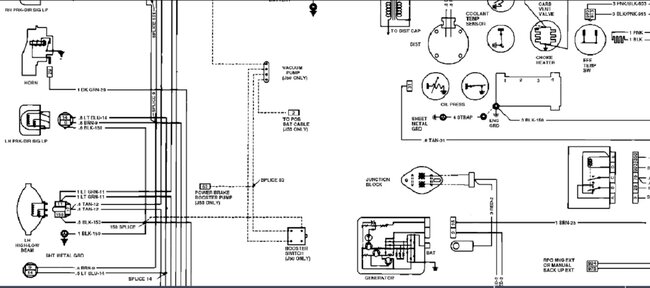

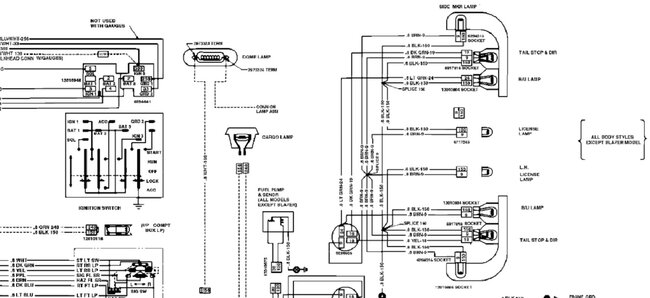

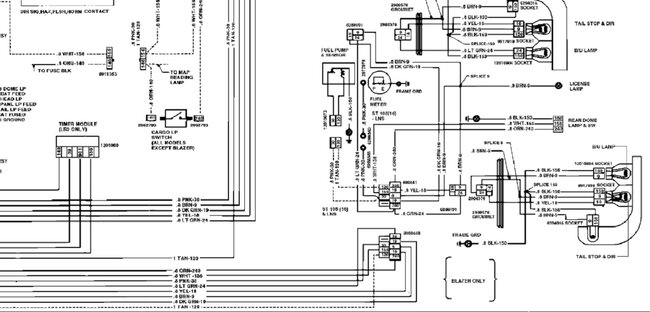

The fourth photo shows the inside of the rear half of the housing. Only half of the main diode block can be seen. They're between the three nuts and the finned aluminum heat sink. The other half is to the right, buried under the stator coil. Three tabs on the diode trio are attached under those three nuts too.

The two halves of this housing can be reassembled four ways by turning one part a quarter or half turn. It will work fine any of those four ways, but only three of them are legitimate. Which orientation the rear half is positioned to depends on the engine size and car model and year. When not rotated to the proper orientation, the rear mounting bolt hole will be in the wrong place, and the wires may not reach the two terminals, or they might not be accessible. All three versions are available at the auto parts stores. In the event the one you need is out of stock, either of the other two versions can be used, but the rear half must be turned to match that of the one you removed. Remove the four bolts, then spin the rear half, but do not pull it away from the front half as you do that. If you're repairing your generator, it is standard practice to mark both halves of the housing to know how to reassemble them in the right orientation.

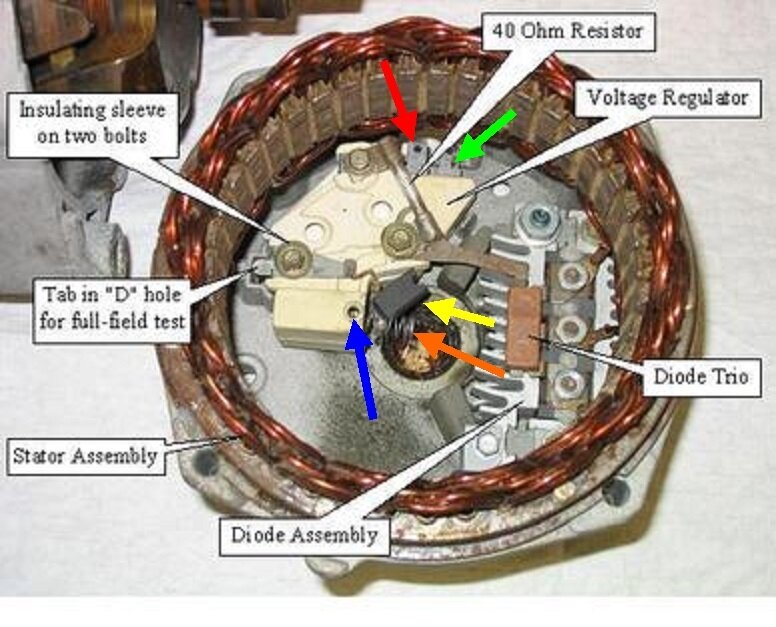

If you accidentally pull the rear half off, stop and refer to the fifth photo. There's two springs, (orange arrow), that get pushed into their tubes by two brushes, (yellow arrow). Those brushes are held on by short braided wires, so they won't fall out. Once both are pressed in all the way, stick a stretched-out paper clip or a toothpick through the hole, (blue arrow) to hold them in. A new voltage regulator comes with a new brush assembly. They will come with a thin wooden stick in that hole holding the brushes in. That stick or paper clip must stick out the hole right behind it in the housing. Once everything is fully reassembled, that stick is pulled out, then the spring-loaded brushes will snap into place. If you do that slowly, you'll hear the two clicks.

For fun, the red and green arrows are pointing to the two terminals you see on the outside.

Testing

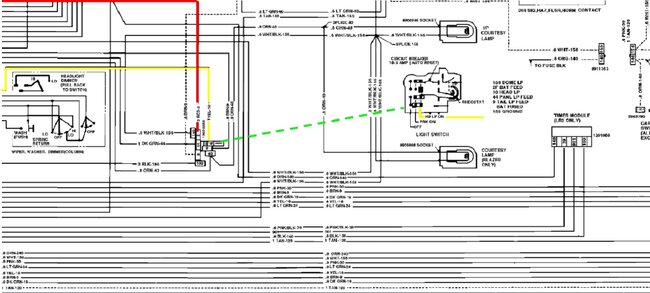

When you measure the charging voltage at the battery, and it is between 13.75 and 14.75 volts, while that is good, it only means it is okay to perform the rest of the tests, but those full-load output current and ripple voltage tests require the professional load tester. When charging voltage is too low, there's one more test you can do yourself, and it's usually pretty easy. There's two different circuit designs for how voltage regulators are connected. Every charging system uses one of those designs. This is important in knowing how to do this test. It involves bypassing the voltage regulator. If the regulator is defective, bypassing it will cause the generator to charge wide-open. It's important to not raise engine speed above idle as doing so can make charging voltage go very high. That can destroy computers and burn out any light bulbs that are turned on. Do this bypass test just long enough to see the results, typically just a couple of seconds.

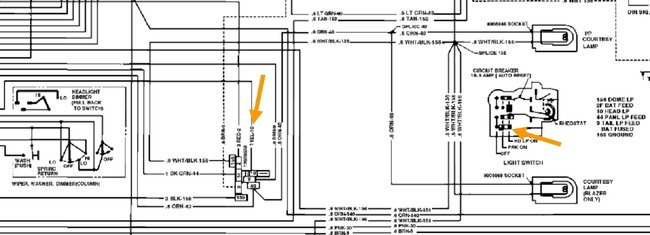

With Ford's regulator design, we have to apply 12 volts to one terminal to bypass it. That's easiest to do right at the regulator, on the inner fender. With Chrysler alternators, there are two wires plugged into it. The blue one is the 12-volt feed for the field coil and the remote-mounted external voltage regulator. The green wire at either location gets grounded to bypass the regulator. That's easiest to do right at the back of the alternator. Newer Fords in the '90s use the same circuit, but have a designated "test" terminal built in on the back of the generator. That also gets grounded.

Your GM generator has the same design Chrysler uses but they provided a test point. In the fourth photo, the "D" hole is pointed out on the left side. The tab is visible through that "D"-shaped hole on the rear housing. Don't worry if you can't see it. You just have to be able to reach it to stick something metal into the hole. A small screwdriver or pick works well. Stick it into the hole until it touches that tab, then move it to one side so it also touches the metal housing. That shorts out that point to bypass the voltage regulator, removing it momentarily from the circuit. Now the generator is "full-fielded" and will charge as hard as possible. If the regulator had been causing a no-charge condition, during this test you'll see system voltage rise noticeably, and / or the headlights will become brighter. You're also likely to hear the whine of the straining generator.

If you do not see voltage rise during the full-field test, chances are the voltage regulator is okay, and something else is causing the problem. For a no-charge condition, suspect worn brushes, especially on high-mileage vehicles. This almost always starts out as an intermittent problem that gets progressively worse over weeks and months. For low-charge conditions, suspect a failed diode. Those can be replaced in one block of three, but since they're snapped together, it's easier to replace the complete block of six. The regulator is already running the field coil as hard as possible to get output current up to where it needs to be, so bypassing it doesn't change anything.

The last failure is that diode trio. The dim "battery' light is the only clue and symptom. This is the least important failure and the repair often gets put off until other repairs are needed.

The question often arises about "upgrading" to a replacement generator with a higher output current. There are also kits available for modifying the generator you already have. All that's needed to get that higher current is to add a few inches of copper wire to the stator coils, and to replace the six diodes with those than can handle the higher current. When contemplating this modification, it's important to remember it doesn't matter what the generator is capable of. They all are just going to develop the amount of current that is needed, and no more. Similarly, a massive water pump can fill a municipal water tower in a few days, but once full, it will only pump as much water as needed to keep the tower full, and no more.

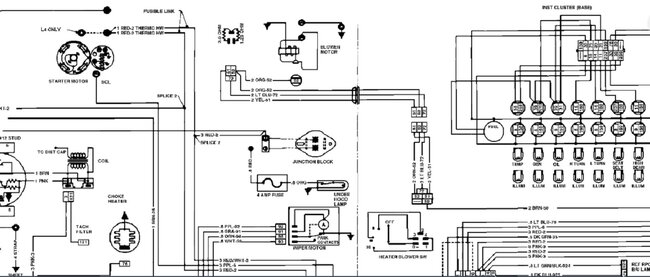

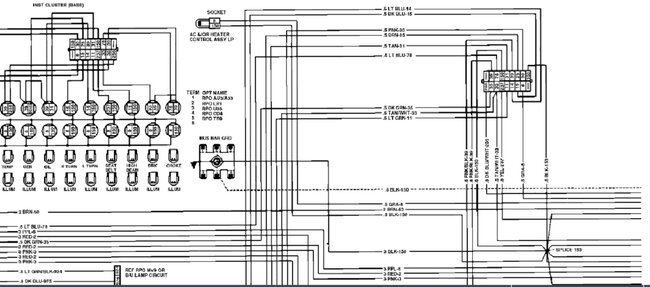

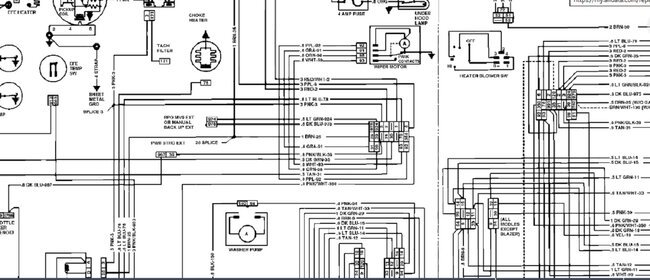

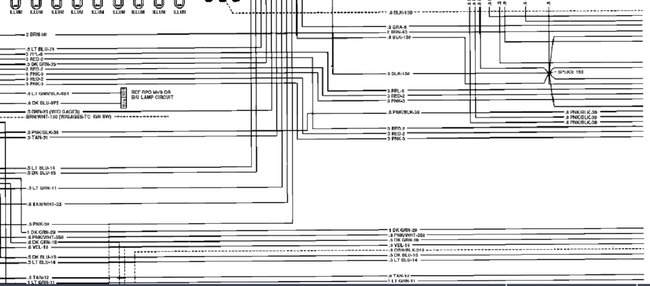

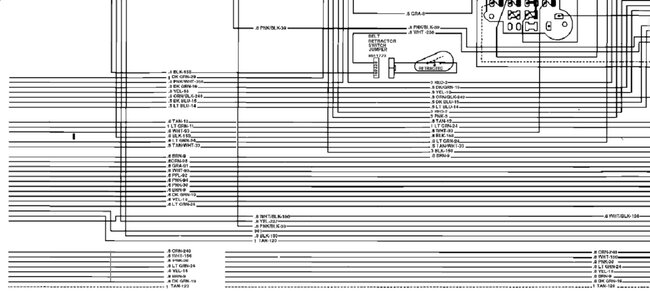

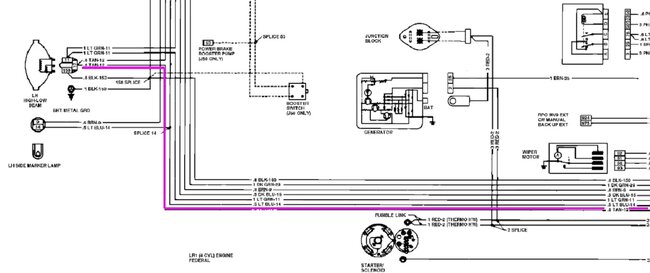

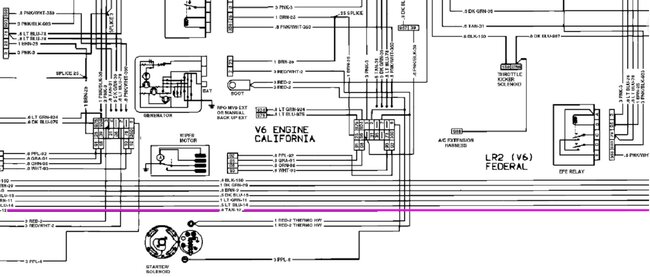

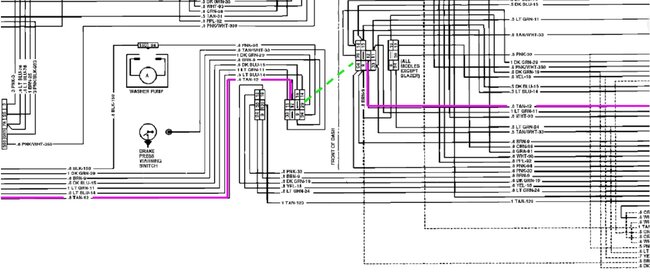

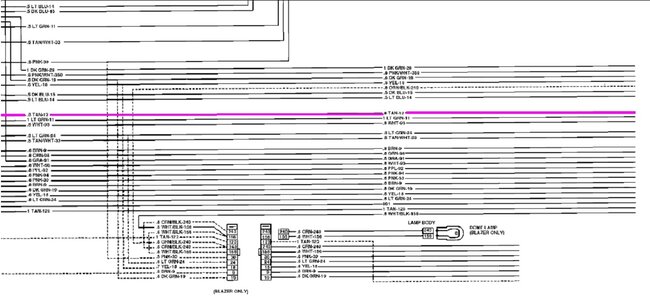

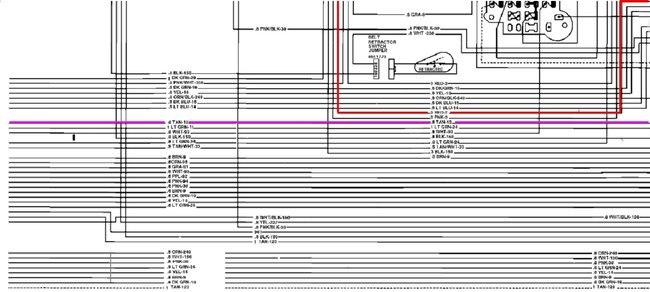

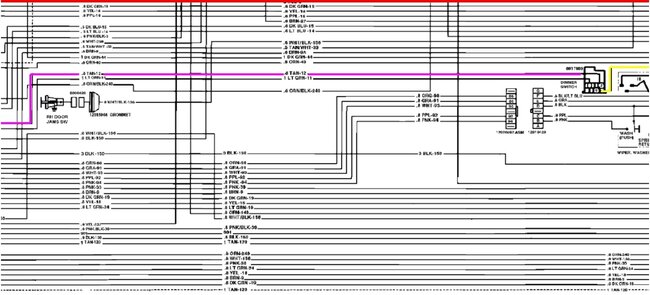

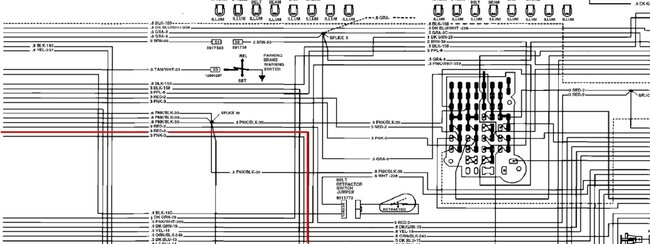

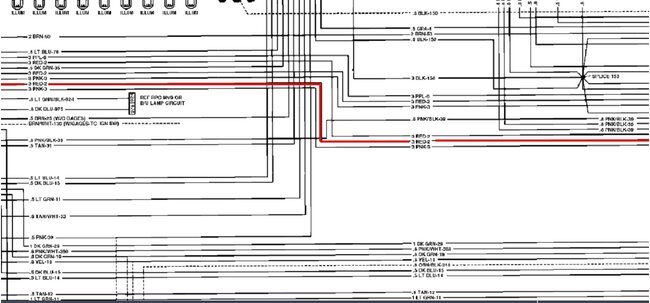

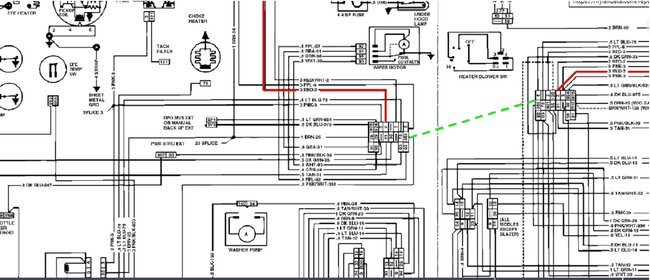

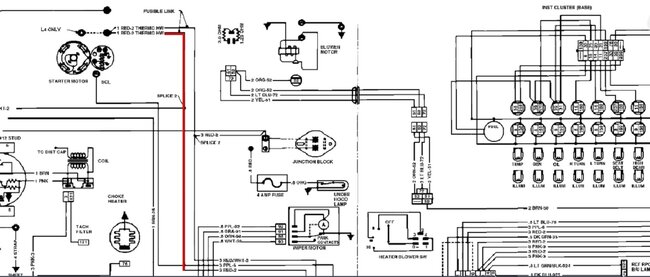

The only time any generator will produce its full rated maximum current is during the professional load test. With the correct size generator, the fuse link wire is large enough to handle that for more than the few seconds the test takes. It's when a larger generator is installed that this can lead to trouble. It works just the same as the original one, until that full-load test is performed. The larger unit's maximum current can exceed the rating of the fuse link wire and cause it to burn open. For those applications that use the larger generator, a larger fuse link will be used, as well as possibly larger wire for the rest of that circuit. Often you'll find three different fuse link sizes listed on diagrams for multiple different applications. Always replace one with another of the same gauge and insulation color.

That covers everything I can think of related to generator failures. You won't be tested on this, so just tell me what you find for voltages, then we'll figure out where to go next.

Images (Click to make bigger)

Monday, March 27th, 2023 AT 4:07 PM