It is strange that our database does not have the labelling of the fuses.

Go through the following and see if you can come up with anything.

DIAGNOSTIC PROCEDURE

1. CHECK IVT CONTROL SOLENOID VALVE POWER SUPPLY CIRCUIT

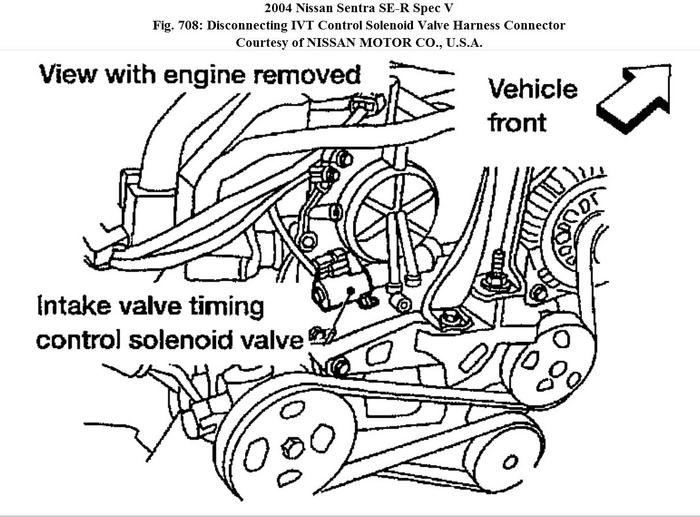

a) Turn ignition switch OFF.

B) Disconnect intake valve timing control solenoid valve harness connector.

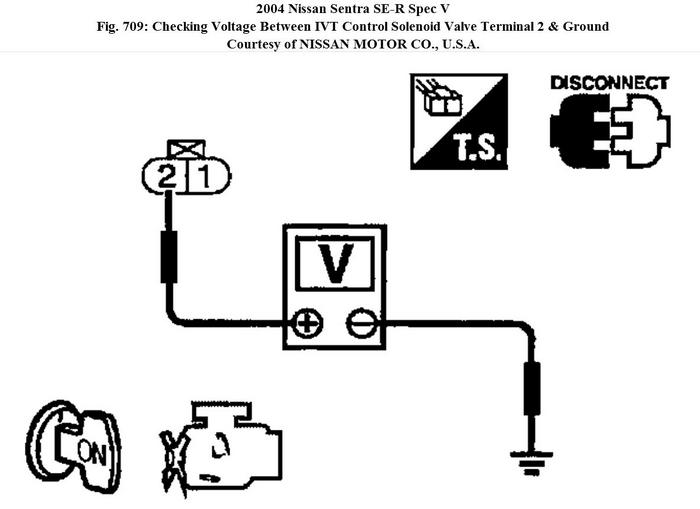

C) Turn ignition switch ON.

D) Check voltage between intake valve timing control solenoid valve terminal 2 and ground with CONSULT-II or tester.

Voltage: Battery voltage

OK or NG

OK: GO TO 3.

NG: GO TO 2.

2. DETECT MALFUNCTIONING PARTS

Check harness for open or short between intake valve timing control solenoid valve and ECM relay.

Repair harness or connectors

3. CHECK IVT CONTROL SOLENOID VALVE OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

a) Turn ignition switch OFF.

B) Disconnect ECM harness connector.

C) Check harness continuity between ECM terminal 11 and intake valve timing control solenoid valve terminal 1.

Continuity should exist.

D) Also check harness for short to ground and short to power.

OK or NG

OK: GO TO 4.

NG: Repair open circuit or short to ground or short to power in harness or connectors.

4. CHECK INTAKE VALVE TIMING CONTROL SOLENOID VALVE

Refer to "COMPONENT INSPECTION ".

OK or NG

OK: GO TO 5.

NG: Replace intake valve timing control solenoid valve.

5. CHECK INTERMITTENT INCIDENT

Refer to "TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT ".

INSPECTION END

COMPONENT INSPECTION

INTAKE VALVE TIMING CONTROL SOLENOID VALVE

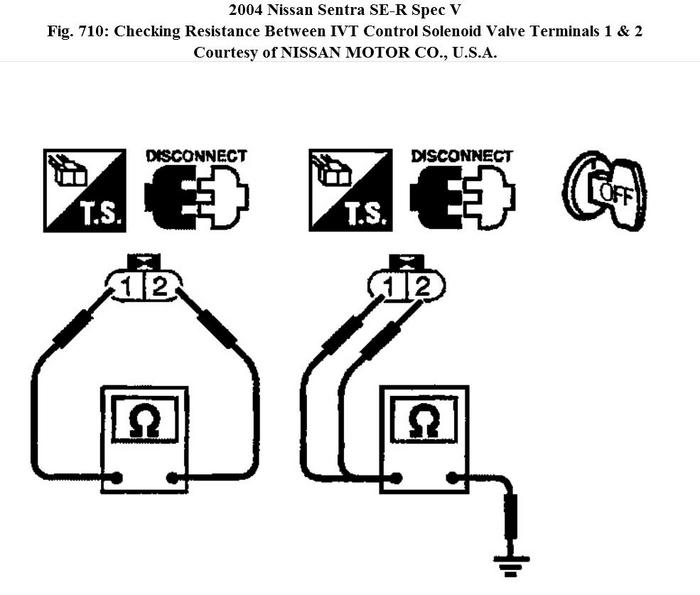

1. Disconnect intake valve timing control solenoid valve harness connector.

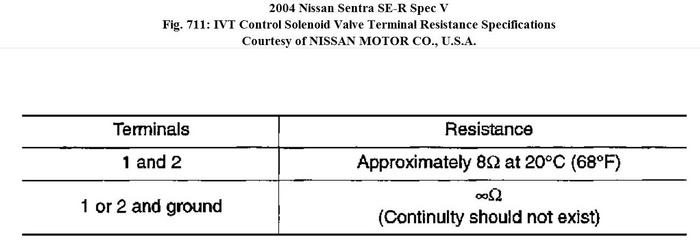

2. Check resistance between intake valve timing control solenoid valve terminals 1 and 2 under the following conditions.

Refer to diagram.

Images (Click to make bigger)

Saturday, July 30th, 2011 AT 3:59 PM