I actually did this kind of stuff to a dozen cars. Each car had up to 50 switches to create defects I called "bugs" for my students to diagnose. Some symptoms, like the inoperative starter, could have up to five or six switches in different places within the circuit. The kids just had to narrow each one down to between the closest available test points, meaning connector terminals, relay socket terminals, and things like that.

You also must decide whether you want any modification to be permanent or easily removable. Leaving extra wires can cause a lot of confusion for the next owner of your truck if they have to find a problem in that circuit.

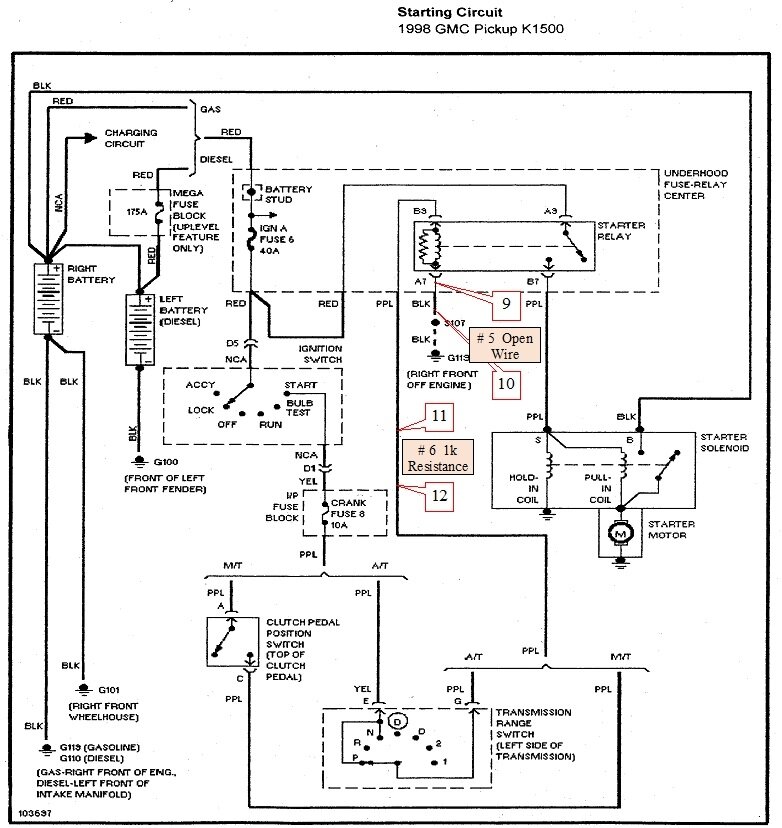

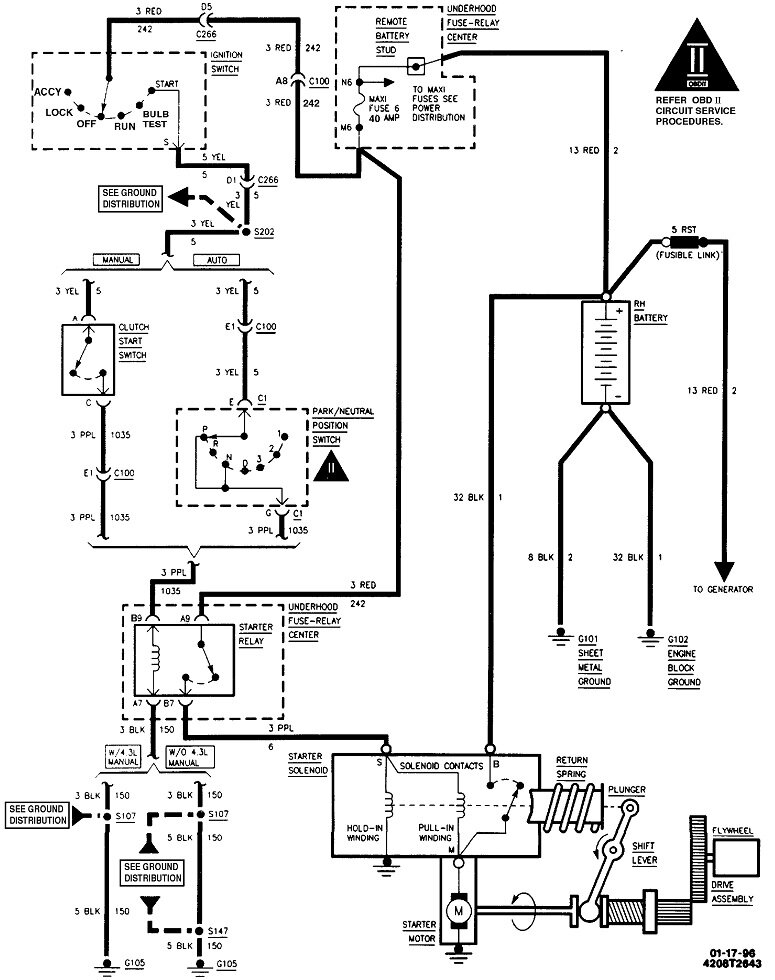

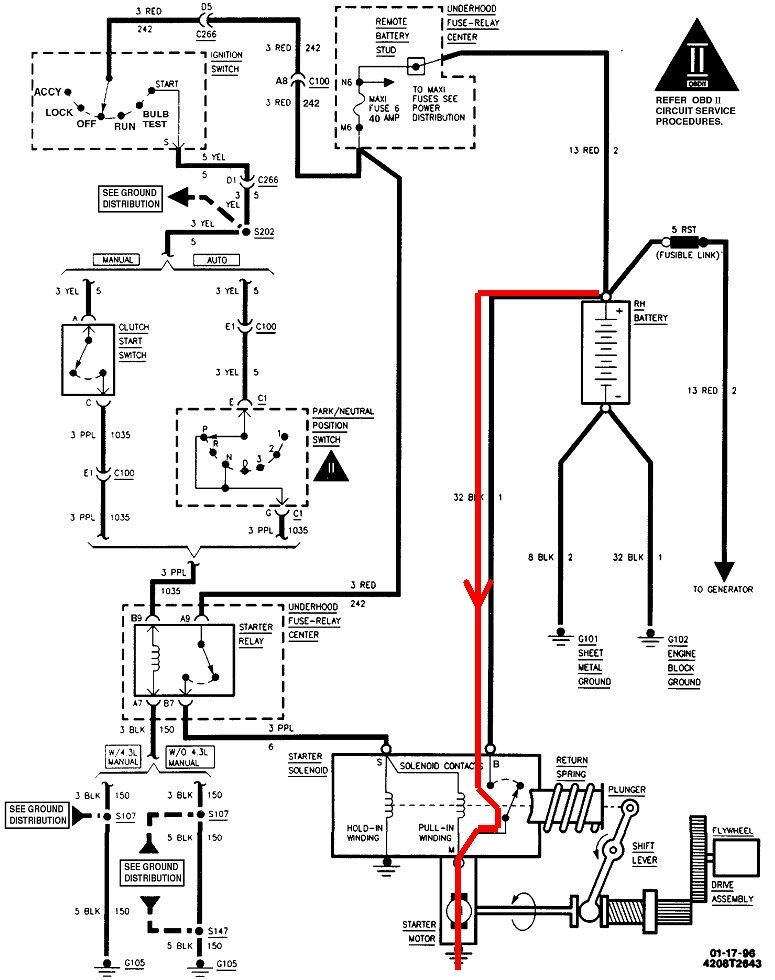

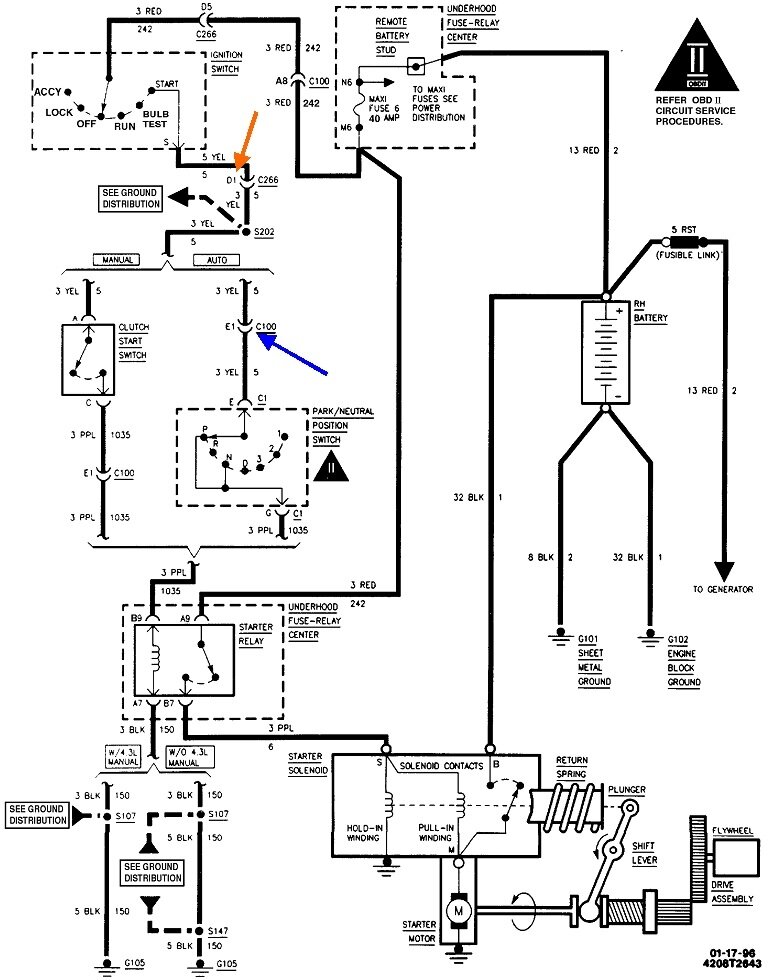

This first diagram is from my notes to myself for the two switches I put in the starter circuit of a '98 GMC that was donated to my program. It's drawn a little different, but it's basically the same as for your truck. Your diagram is in the second image.

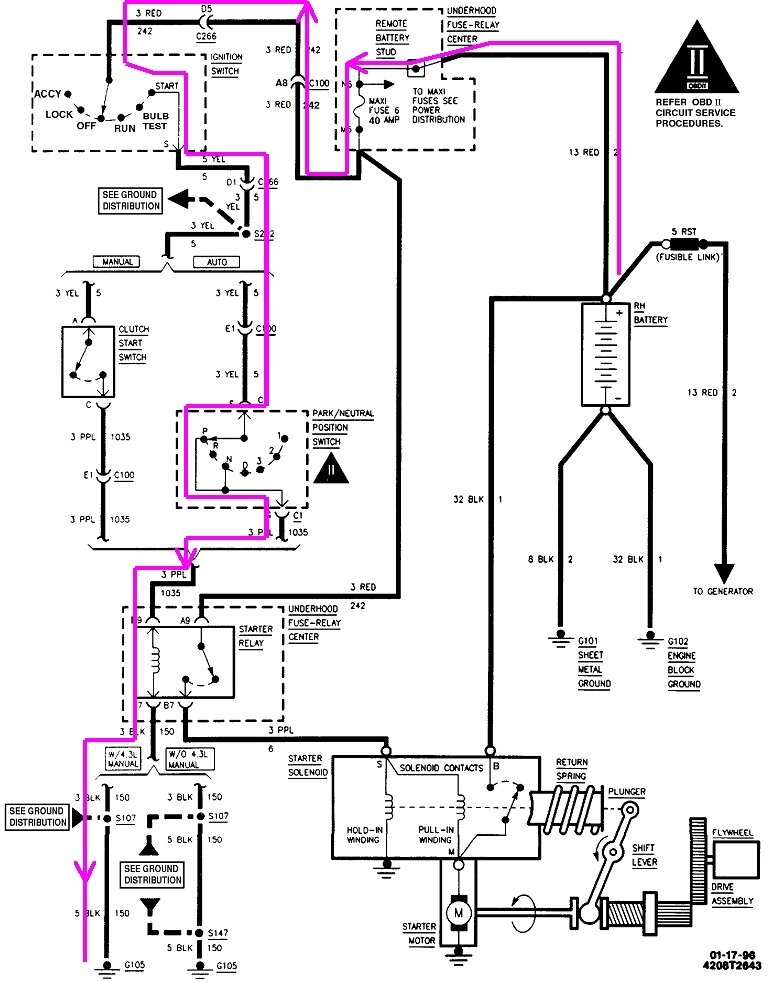

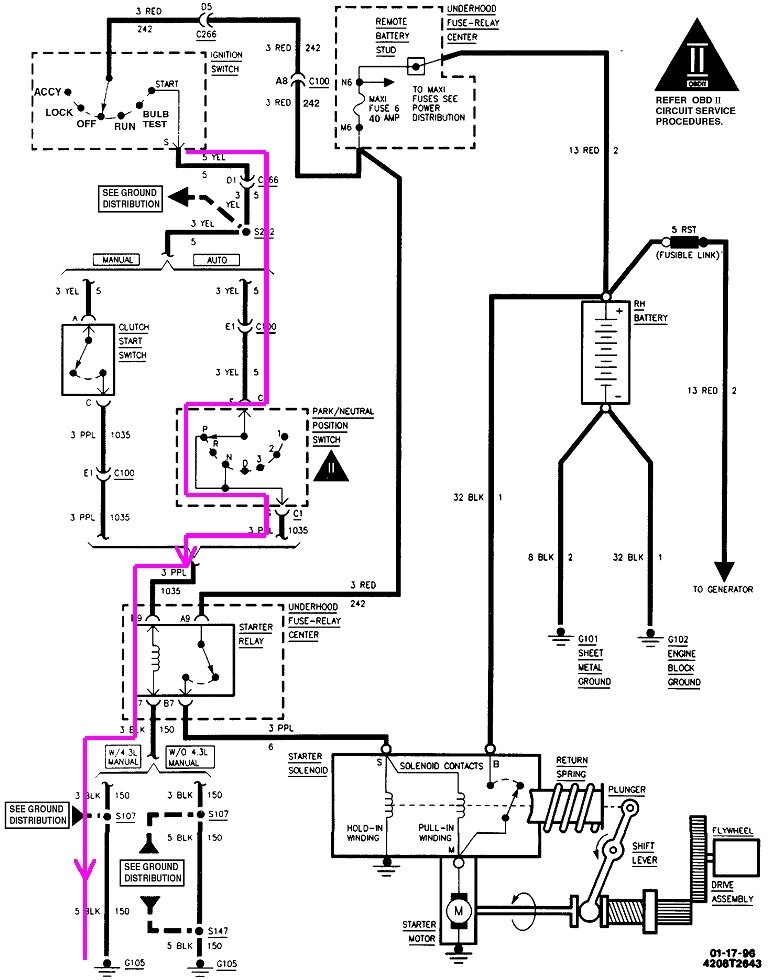

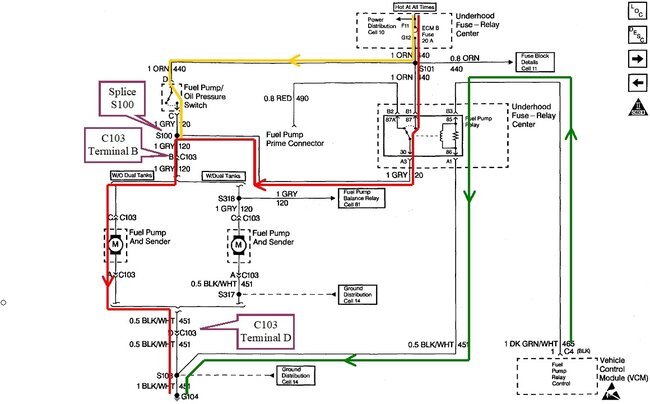

For reference, all starter circuits can be broken down into three parts; the low-current circuit, the medium-current circuit, and the high-current circuit. In the third diagram, I traced the low-current circuit in purple. Current will be very low, as in much less than one amp. Switch contacts can easily handle that, and the wires can be a small diameter. This is the circuit where you'll want to put the added-on switch.

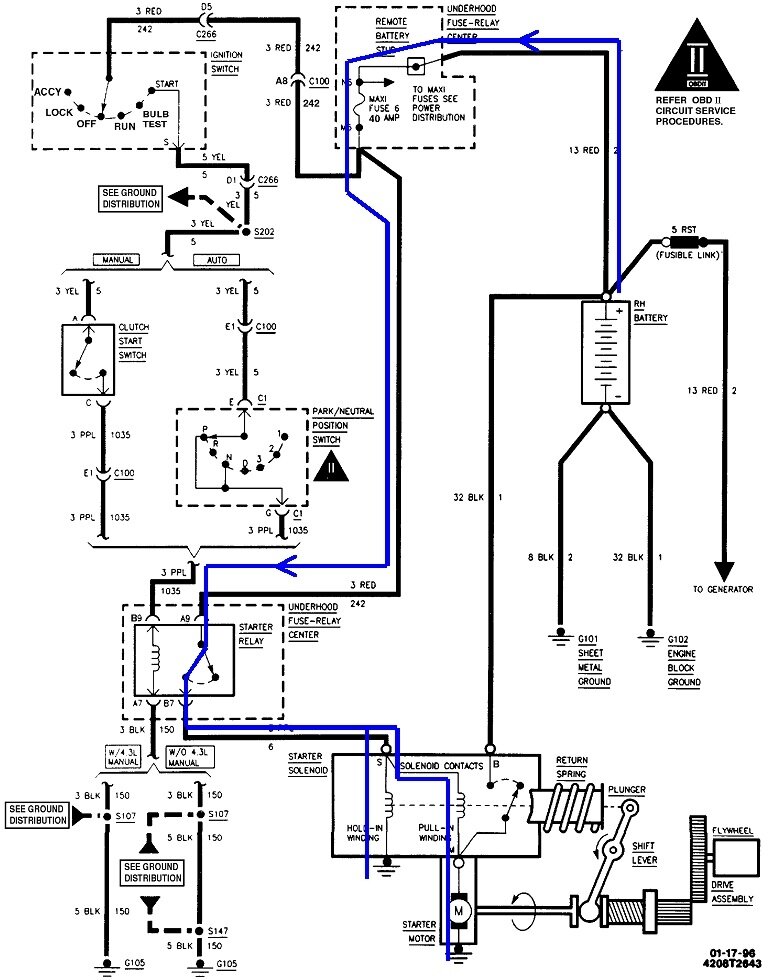

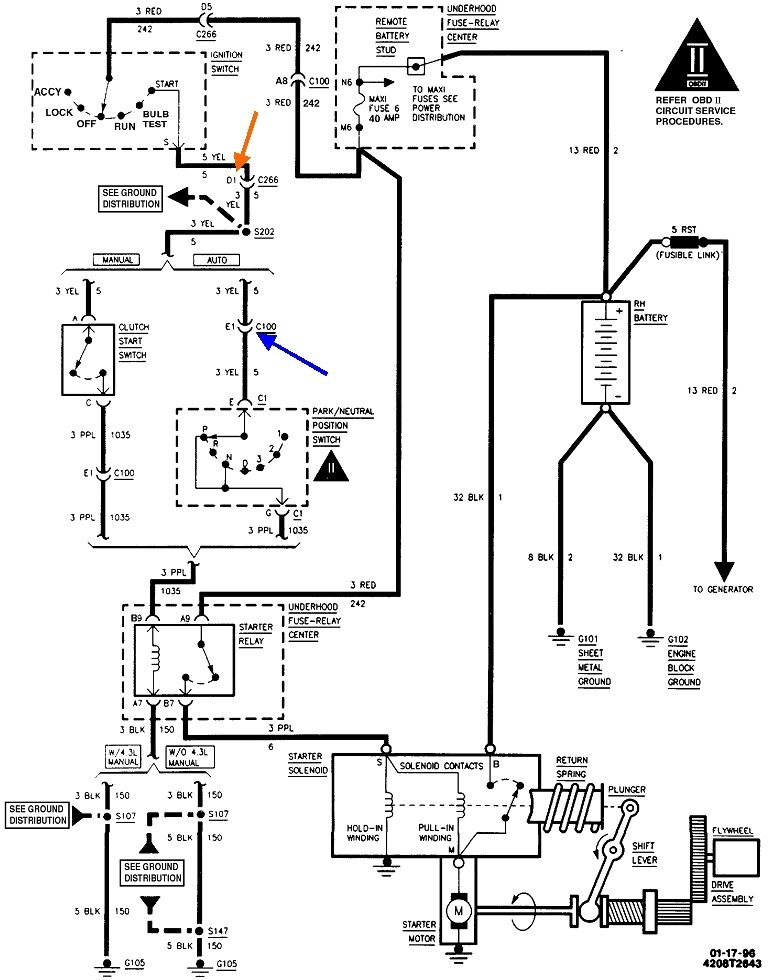

To complete the story, the ignition switch in "crank" sends current through the neutral safety switch, then the coil of the starter relay and turns it on. When that relay turns on, the medium current flows through the relay's contacts, then through two coils inside the starter solenoid on top of the starter motor. In the fourth diagram, that circuit is in blue. The electromagnetic fields are needed from both coils to build enough strength to pull the drive gear into engagement with the ring gear. Current through the "hold-in" coil goes to ground. Current through the "pull-in" coil continues on through the starter motor itself which has extremely low resistance, so it's like it's just a piece of wire. Total current flow through the two coils is around 10 to 15 amps. That's too much for the contacts in the ignition switch, but the relay can handle that.

Once the solenoid has engaged fully, a contact switches on the high-current circuit shown in the fifth diagram in red. This can be as high as 300 amps to get the starter motor spinning. Once it's up to speed, that will quickly drop to less than 200 amps. Due to that very high current, connections must be near perfect, but it's where we'll find most problems. It's also the least complicated part of the system. One note of interest here, once the solenoid switches on, battery voltage is applied to the starter motor right at the point where the pull-in coil is connected. That puts full battery voltage on both sides of that coil which bypasses it. Once the drive gear has engaged, it takes much less energy to hold it in place during cranking. By bypassing it, that few amps becomes available to go through the starter motor too. That little bit extra can be just what's needed on a real cold day to get an engine started.

Finally, in the sixth diagram, I outlined the section where you can cut in and add a switch. That can't be done in the part between the battery and the ignition switch because that feeds everything else controlled by that switch, such as the heater fan, radio, wipers, and power windows. That section can have rather high current, in the area of five to ten amps. You'd need a pretty beefy switch there.

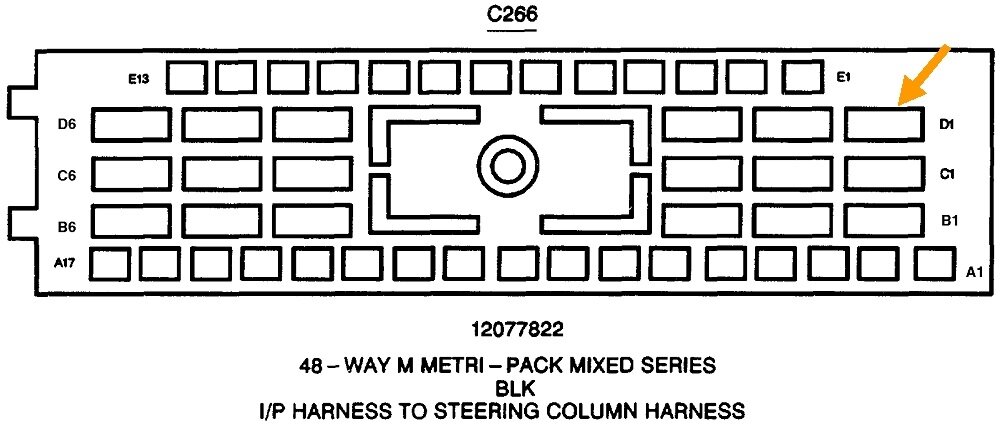

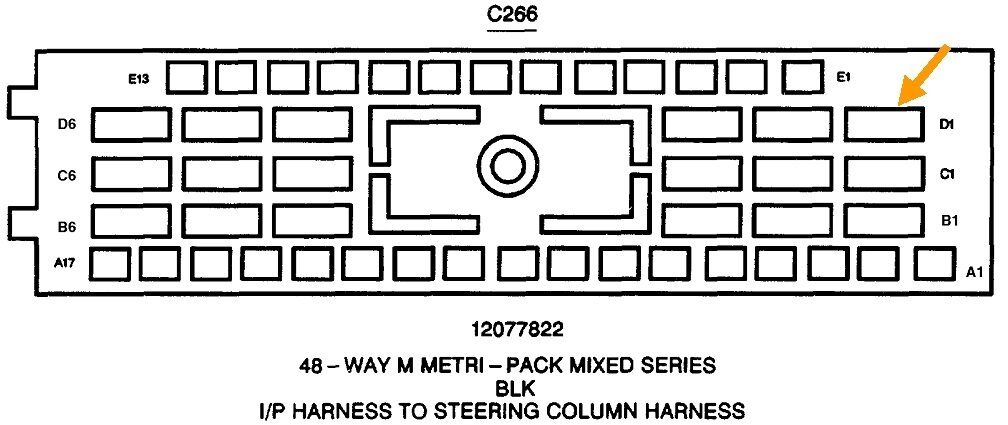

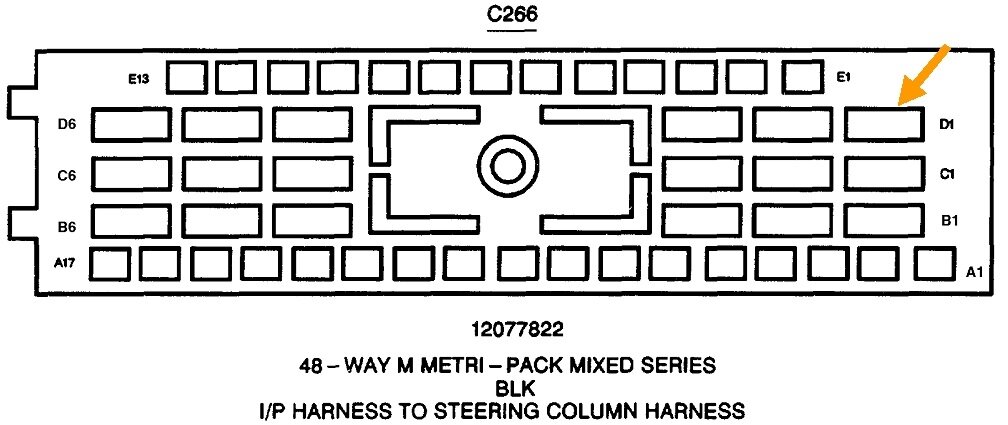

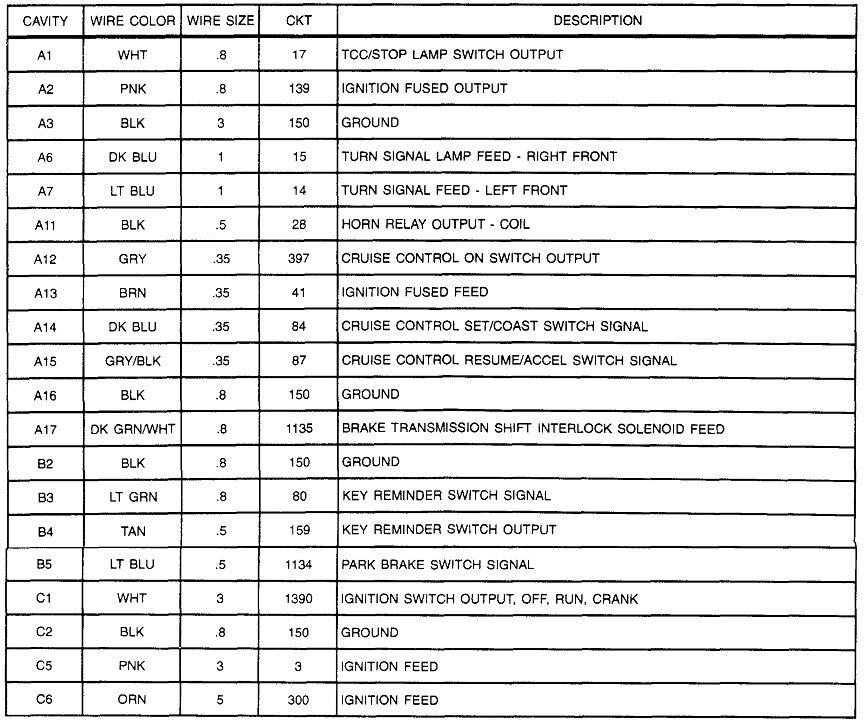

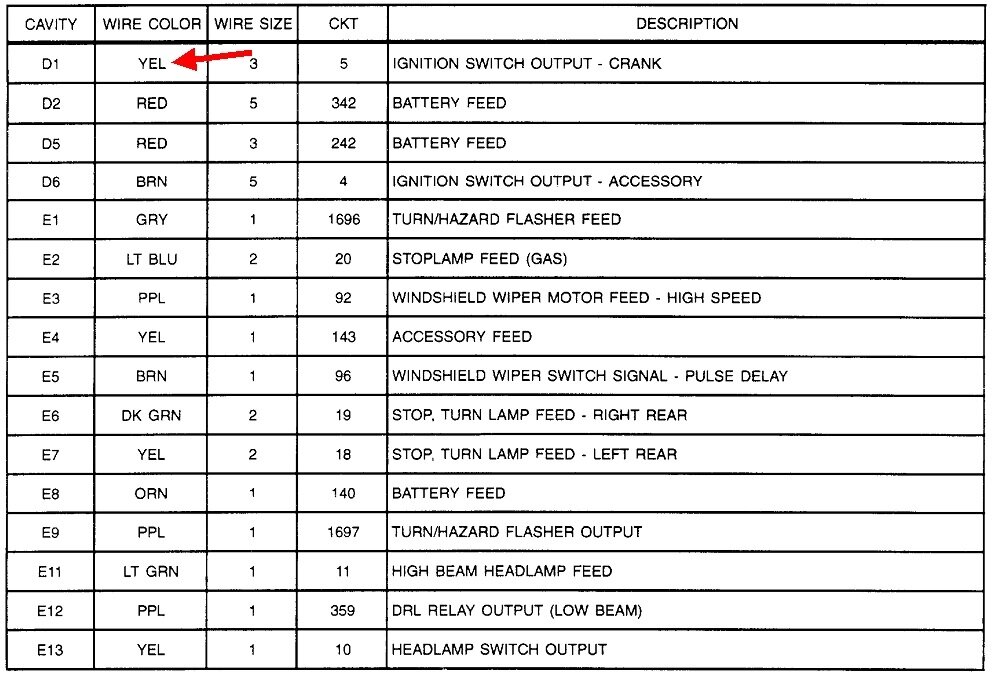

My preference would be to stay inside the cab. Look for connector C266 under or near the steering column. The diagram shows terminal "D1" as a yellow wire for this circuit. That's shown in the seventh drawing. If you plan on making this permanent, just cut that yellow wire on either side of the connector and extend them to the new switch. I like to be able to put things back the way they were, so the way I'd do this is to visit a pick-your-own-parts salvage yard, and pull out that wire with both of the mating terminals from the connector. On your truck, pull one of the terminals out of your connector and plug it into one of those you just harvested. Plug the other one into the connector. If you were able to get enough wire with each terminal, they might reach to the new switch, otherwise you'll just have to add some additional wire. Either solder the wires to the switch terminals, or you can use crimp-style universal terminals, but I always solder them too.

If you use a toggle switch, you'll have to remember to switch it to "No-Crank" mode every time you want it to do its thing. If you use a momentary push button, it's set automatically, but you'll have to press it every time you want to start the engine.

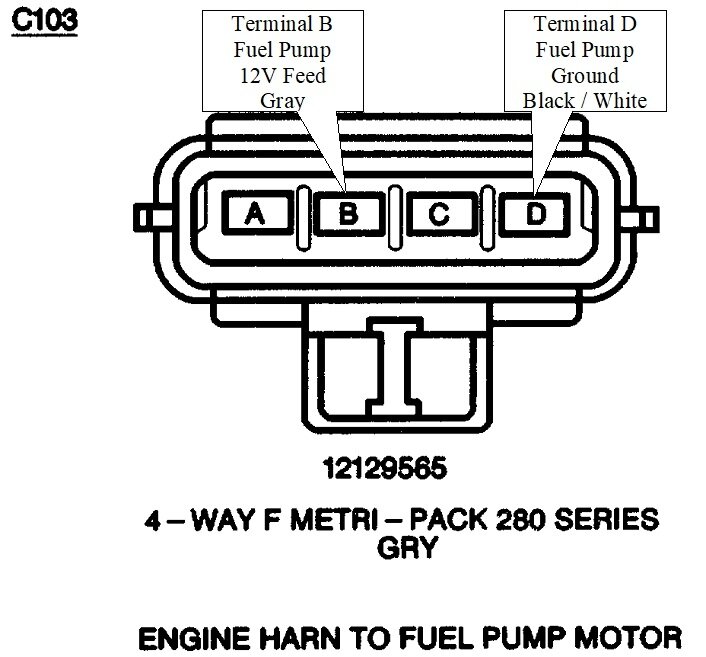

I'll work on the fuel pump circuit next, but that one will require going outside the cab, either under the hood or in back under the box.

By the way, if you need to make the diagrams bigger, copy and paste them into a typing program such as MS Word where they can be expanded. I can help with that if necessary.

Images (Click to make bigger)

Thursday, January 18th, 2024 AT 6:01 PM