Thanks Joe. On the ground I am going to be certain and loosen the bolt tomorrow because the small cable going into wiring harness is behind the large cable on the bolt and I cannot see it. The bolt is tight, the cables seem attached well when I try to move them, but they are covered with cable panduit.

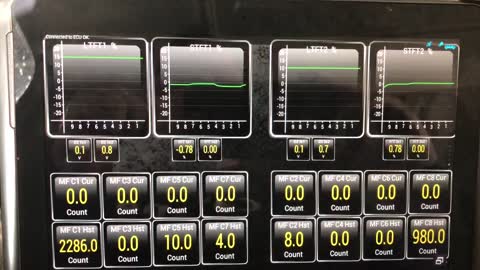

I am only getting P0300 code and none of the 301-308 codes. My cheap Ancel AD310 plug in is limited. However, today I purchased Torque Pro application and it does more. It shows me the cylinder current and history misfire data. I am not a mechanic and not sure what is normal but I am now aware 1 and 8 seem to be the culprits.

I am attaching my dashboard I built. It is a video of me accelerating hard, then slowing down. Left side is all bank 1, right side bank 2. Graphs are LTFT and STFT, small icons are O2 and Trim sensors, and bottom are cylinders left to right as 1, 3, 5, 7 then 2, 4, 6, 8 showing the current misfires on top row and history on bottom row.

Plugs are new, plug cables are new, coils original but have been swapped around with no change. Intake gaskets replaced with Fel-Pro metal frame type and torqued to spec (89 in pounds). Injectors are new ($120.00 set off Amazon), CAM sensor new, MAP new, Purge Solenoid new, Throttle body new, Fuel Regulator new, fuel filter new (Fuel pressure 42 psi per spec for 2004 Tahoe 5. Z Flex), all hoses and lines on intake new except the fuel purge tube is original. Original MAF but I did clean it.

I built a smoker can that connects to bicycle pump and smoke test passed with flying colors. No smoke from intake anywhere, but after pumping for a couple minutes I do see smoke from oil dip stick tube.

Compression testing on cylinders 2-8 is 179-186 psi (4% variance), cylinder one dry test is 160 psi, wet test 160 psi, but it can reach 180 psi if I double the start cycles from 5 to 10 count. It reached 151 psi after only to cycles and have read that 80% of pressure should occur in first two cycles.

Leak down on number one was 85/80 (5% leakage) with leak detected mostly at throttle body and some from oil inlet. I forgot to listen to exhaust. I want to think pressure measurements are okay for combustion to occur? Tomorrow or Sunday I will leak down test #8.

I am not rich but car is paid off so I have thrown parts and new tools at it just to learn how to do it. If I can fix it myself I basically get experience and tools for free I can use in future.

I have also pulled the valve covers off and connected coils so I could watch valves. All sixteen valves are moving /rockers/springs clicking so I understand this means lifters are working and thus camshaft loves are okay? I replaced valve cover gaskets also.

Video (Click to make bigger)

Friday, November 23rd, 2018 AT 5:42 PM