Thank you for your advice, and yesterday I did the loosing of that bolt. The bolt started to show more thread but the pulley stayed firm in its place. I tried to push it down in order to release the belt. Nothing happened, I went afraid that I maybe did something wrong, and tighted back the bolt to its former status.

After that, I wrote you the question about the steps, and it seems that I was doing right, but the pulley won't move.

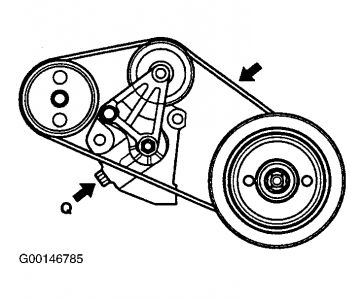

My question is, what do I do next? After releasing the tensioner bolt, can I hit the pulley down using a rubber hammer? Do I must spray D-40 to the pulley?

Actually, this situation of the still standing of the pulley is the reason why I asked you about the removing of the belts I the first place, because I thought that I maybe need to loose other bolts or similar.

Monday, November 8th, 2010 AT 6:09 PM