If I read that right, you have a long crank time, but once the engine starts, it keeps on running okay. Stop me if I have that wrong. This is the typical symptom for fuel pressure dropping when the engine is stopped. It should hold for weeks, but for sure at least overnight.

You should hear the fuel pump run for one second when the ignition switch is turned to "run". That is to insure fuel pressure is up for starting in case it dropped a little. That one second is not long enough if the pressure dropped real far or to zero. The pump doesn't resume running until the Engine Computer sees engine rotation, (cranking or running). That means if fuel pressure had dropped a lot, it can take some time for it to build back up to where the engine will run, and to add to the misery, battery voltage is drawn down to as low as ten volts during cranking. That means the fuel pump will be running considerably slower than normal at that time. Fuel pressure builds too slowly, and some will be bled off by the injectors trying to fire.

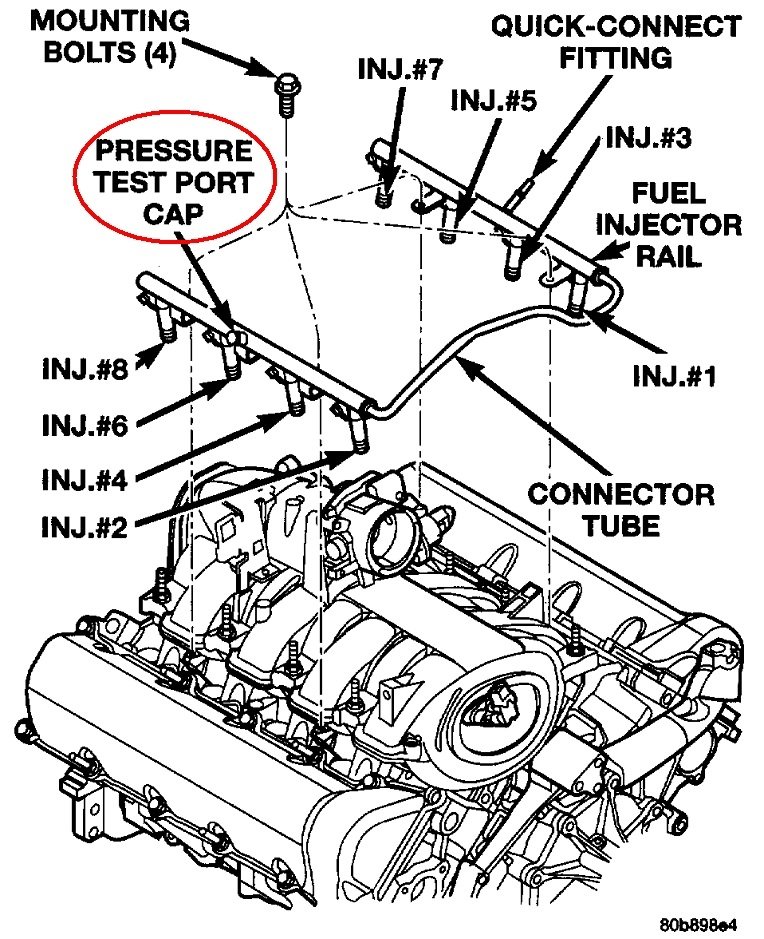

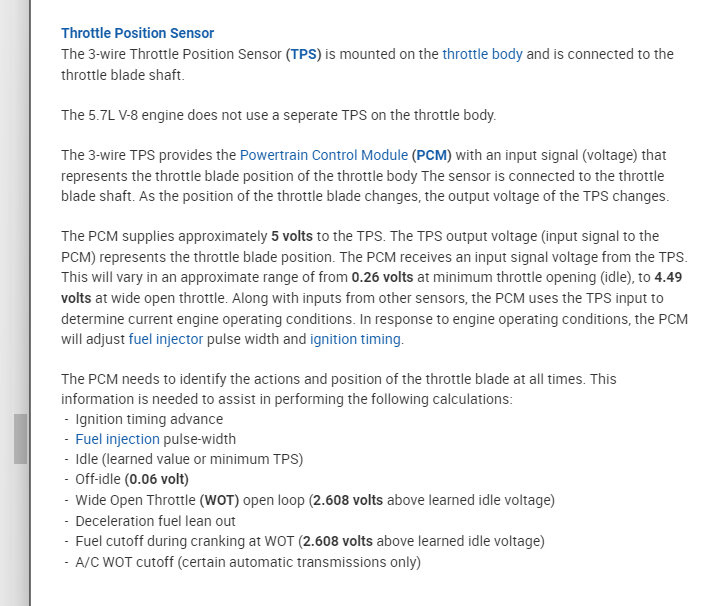

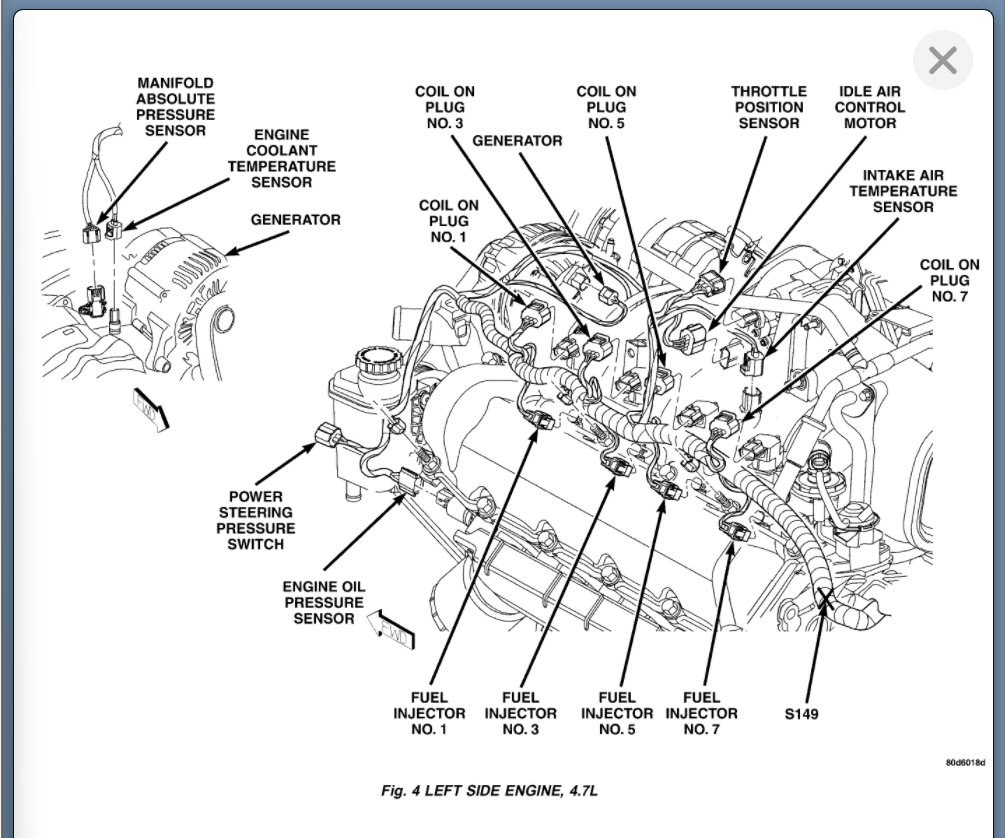

There's two ways to verify this. The proper way is to connect a fuel pressure gauge and watch what happens when the engine is stopped. I circled the fuel pressure test port in the drawing below. The second way to get a clue is to cycle the ignition switch multiple times before cranking the engine. The pump will run for one second the first time the ignition switch is turned to "run". Turn it off, then back to "run" a second time, and perhaps a third time, then crank the engine. The pump will have run longer and built more pressure. The engine will start quicker if fuel pressure is the problem. I don't recommend cycling the ignition switch more than three times. On some models, the cranking system will be locked out after three attempts, then you have to wait a minute or more before resuming. That can let the pressure bleed off again.

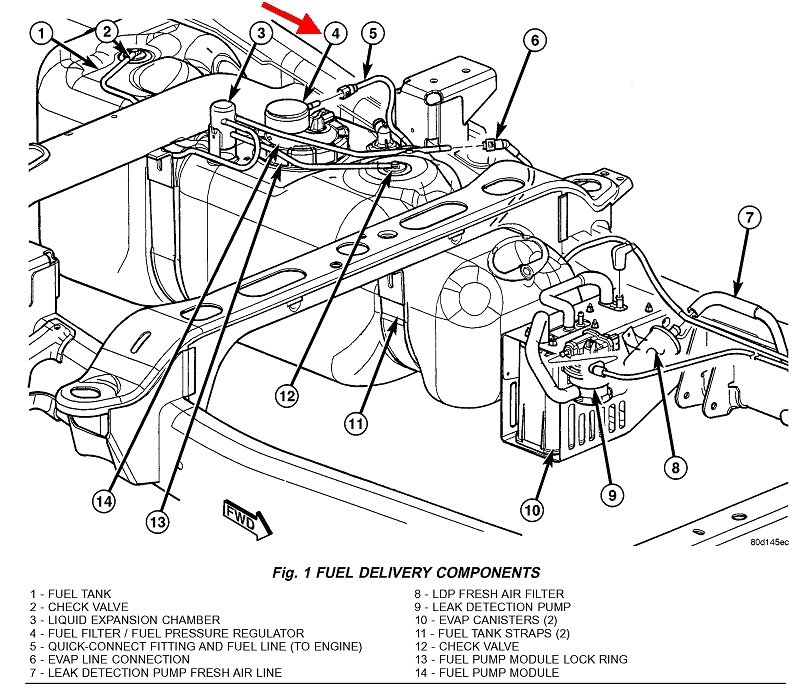

If you verify we're on the right track, there's four places fuel pressure can bleed down. The least common is through the check valve in the fuel pump. To find that, use a hose pinch-off pliers to block the supply hose where it transitions from the body to the engine. That will maintain pressure at the test port while it drops on the tank side of the pliers.

Another place is through a leaking fuel pressure regulator. This doesn't apply to your engine, but for those older models where the regulator is on the fuel rail, excess fuel passes through the spring-loaded regulator, then back into the tank. Use the hose pinch-off pliers to block that smaller return line. If the regulator is leaking, fuel can't get past the pliers to bleed down, so pressure will stay up. That style regulator is shown in the second drawing.

The third place also doesn't apply to your truck, but for the benefit of others researching this topic, it's the rubber o-ring with the red arrow in the second drawing. I've been involved with two of these, one on a brand-new car just delivered to the dealership, and one on a high mileage model. The owner refused to buy the 25-cent o-ring so we had to let the car go that way. Both had a very long crank time, but the engines ran fine once started.

The clue to a leaking o-ring is when the engine is stopped, fuel pressure drops to "0" within a few seconds. If the regulator's valve is leaking, it will take longer for pressure to drop; perhaps as long as two or three minutes. The two o-rings I found were cut. That's an issue with the person who installed those regulators. It's not something that develops on its own over time.

The third drawing is for your 2003 model. It shows the newer-style pressure regulator back at the tank. I haven't heard yet of someone solving a problem by replacing that type.

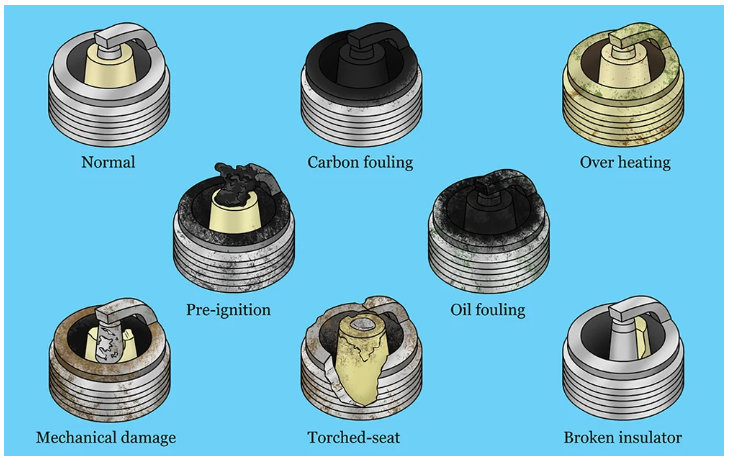

Probably the most common cause of dropping fuel pressure is a leaking injector. The clue is with the pinched-off fuel supply hose, (and the return hose on older models that have the pressure regulator on the fuel rail), you will still lose pressure at the test port. With both lines blocked, if fuel pressure drops off, it can only be past an injector or one of their o-rings in the fuel rail. If one of those o-rings is leaking, you'll smell and possibly see the gas seeping out. You're also likely to smell it inside the vehicle. You won't see or smell it if it's leaking from the injector's valve. To identify that, you have to remove the fuel rail with the injectors still attached, then look at each one to see if any are wet. The clue to a leaking injector is it typically takes hours for fuel pressure to bleed down.

Images (Click to make bigger)

Saturday, March 19th, 2022 AT 4:30 PM