Monday, January 5th, 2009 AT 11:12 PM

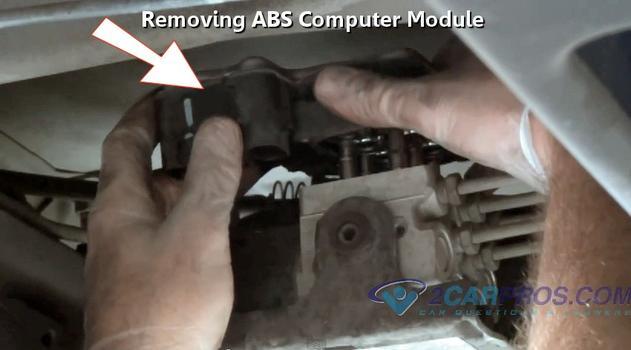

I pulled it down the driveway to test and found the speedometer is out and the o/d off light is flashing. I did some research and found that this is normally caused by the abs sensor in the rear diff (also acts as the vss through gem) so I replaced it. This didnt fix a thing. I checked all the wiring and it looked good. Have not been able to test it yet but will if no other ideas. Could this problem be caused by the G.E.M or the P.C.M?