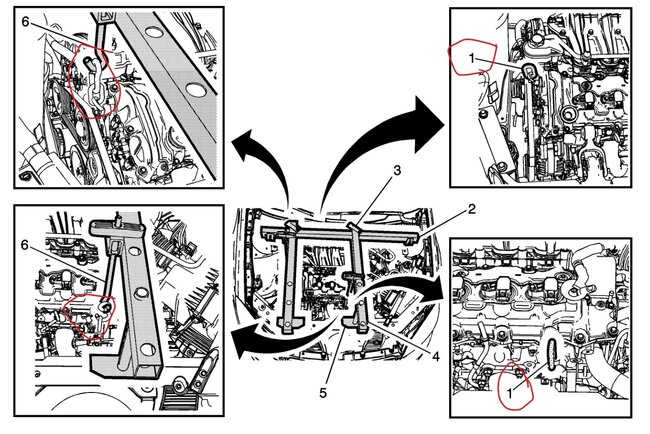

Not useless, you just need some short chains or similar that reach a couple bolts on the engine, those are what you connect to. I just showed the spec tools to give you an idea of how they work. As an example I hang fully assembled big blocks using a plate bolted to the intake manifold. In your case put the bar across the engine bay and see what is below it that is a solid point. Front cover bolts, rear transmission bolts, empty holes in the block. You look for those, then use some quarter inch chain or similar with a longer bolt to connect to those points. The subframe bolts are not that long, They will run out of threads long before you get the clearance you need. What support bar do you have? One like the image? If so they are sold bare because of all the odd options, and you just make up something that works. OH one thing, When you get the balancer out, look at where the seal is seated in the cover. Then examine the snout on the balancer for wear damage from the seal. If you can feel it with a fingernail you can install the seal to a different depth to avoid having the new seal in the groove.

Image (Click to make bigger)

Thursday, August 14th, 2025 AT 5:43 PM