Okay. But these wiring diagrams are completely horrible, thats because theyre older, and I can see quite a few issues with them,

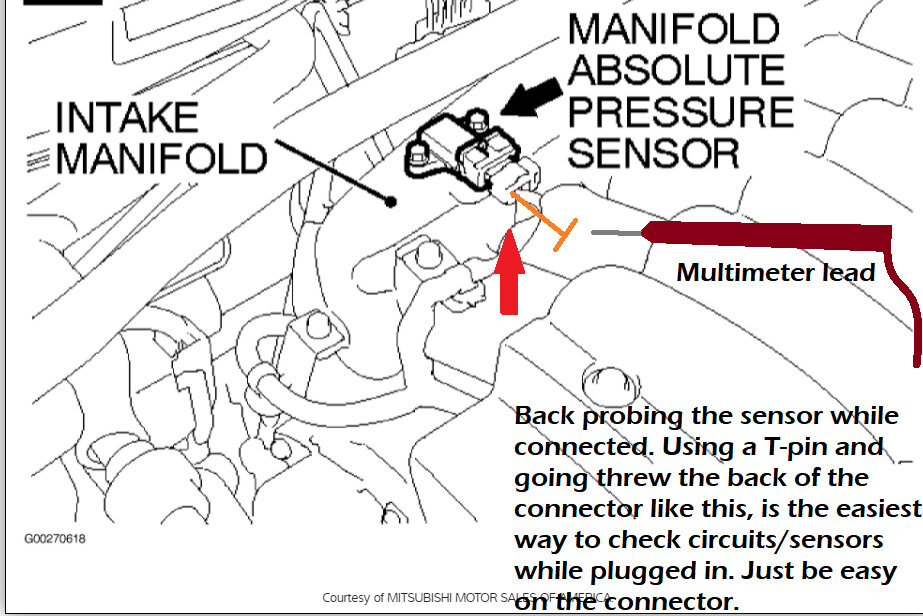

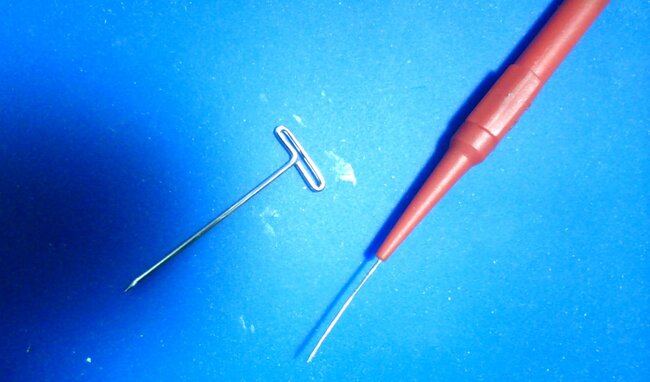

Dont bother with resistance/continuity testing now, right now you are looking for voltage, if it lights the test light up bright, you can verify its a full 12volts with a meter,

using a test light is faster and it puts a small load on the circuit,

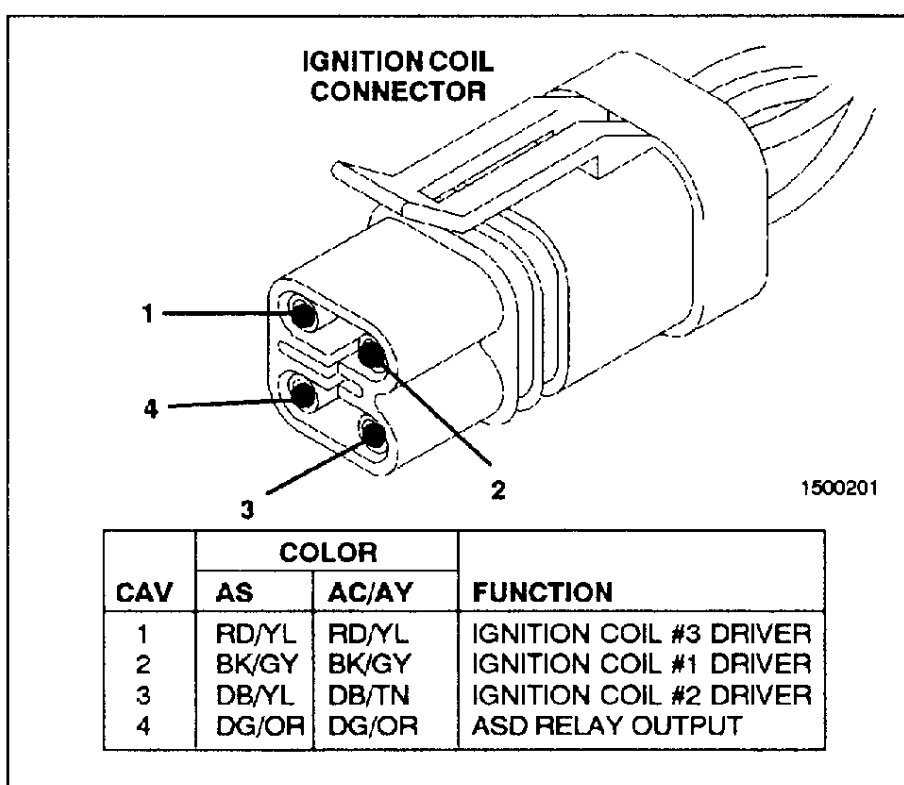

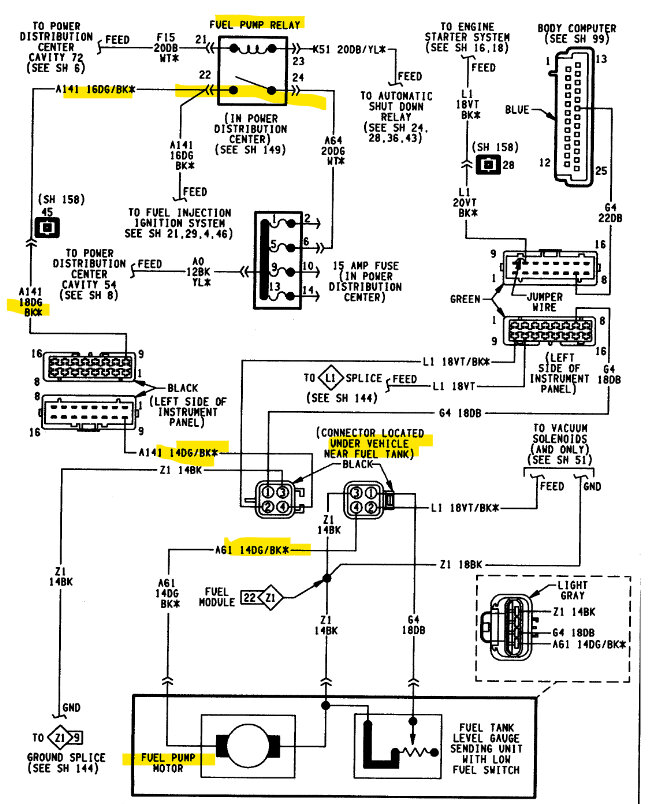

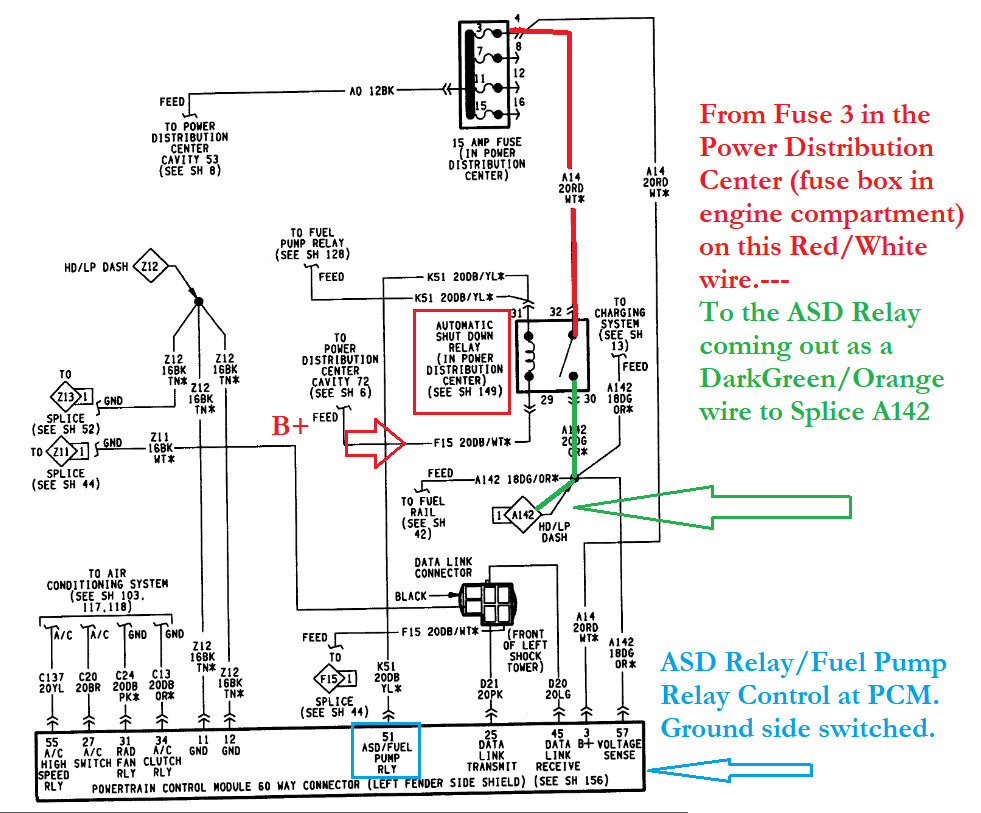

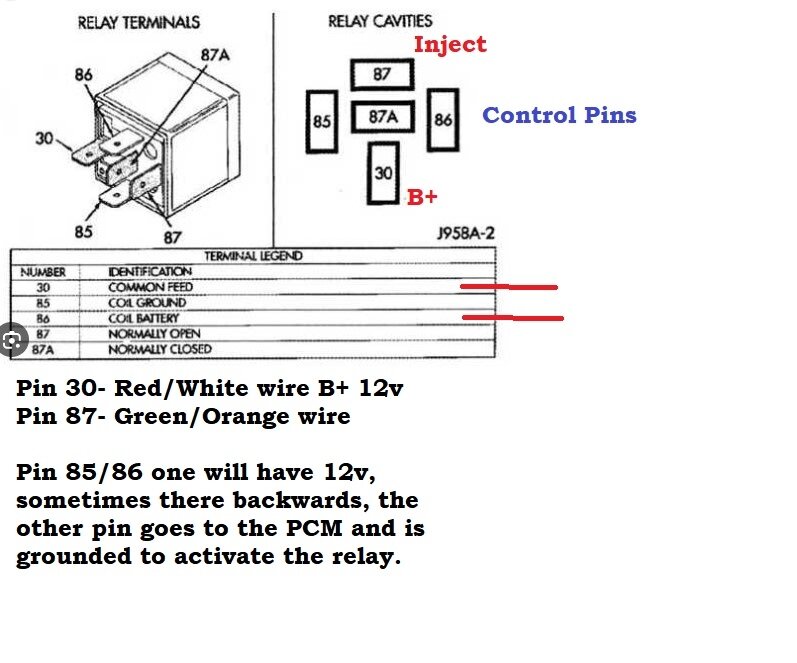

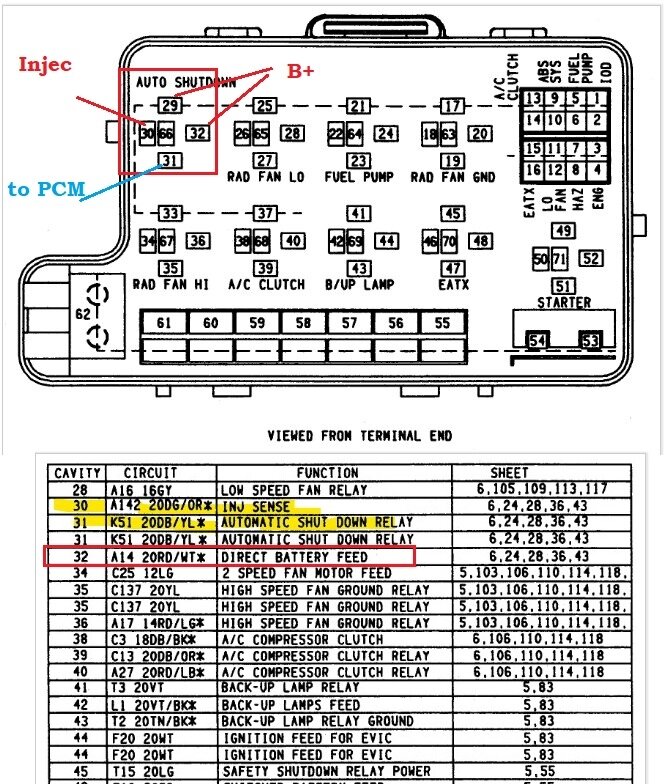

But with the ASD relay out, you should have 12v on two of the pins where the relay sits with the key On, If this is correct, the control side of the relay should be pins 85 and 86, one of those pins should have 12v with the key On, Pins 30 and 87 should be the Load side of the relay, so one of those pins should have 12v.

(And pin 87A is a normally closed contacts with pin 30 until the relay is activated. For now, just verify the 2 hot pins, the PCM should set a code if it doesnt sense power.)

on the Red wire, it should be Red/White. These diagrams have the relay contacts listed backwards in some cases and upside down in other,

So we will just go with basic ASD relay operations.

The Red/White wire going to pin 30 is the constant power feed with the key On, , thats coming from the Fuse #3. But if you have 12v on pin 30 and it lights the test light bright, it should be ok for now.

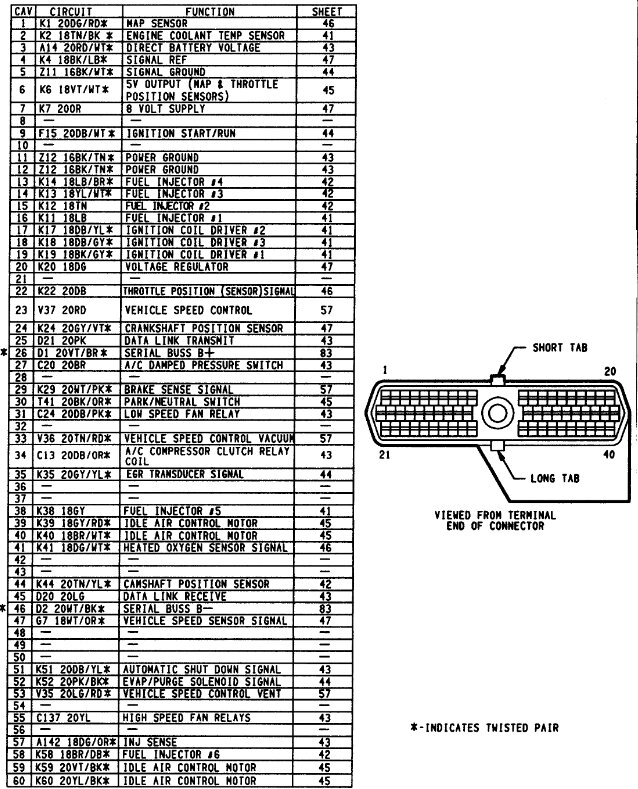

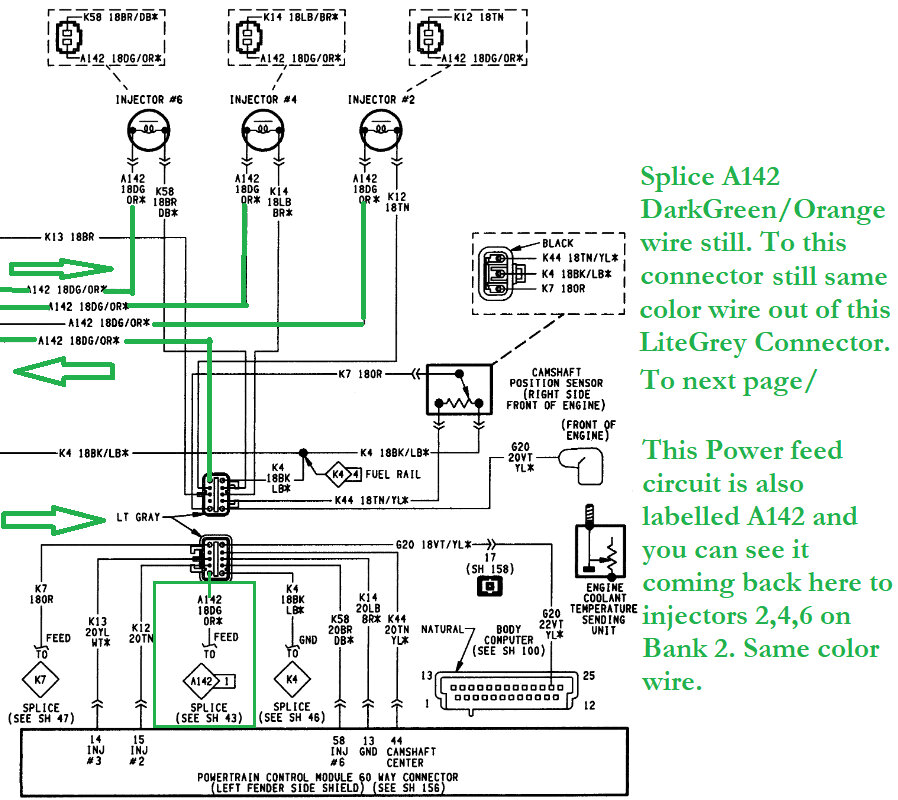

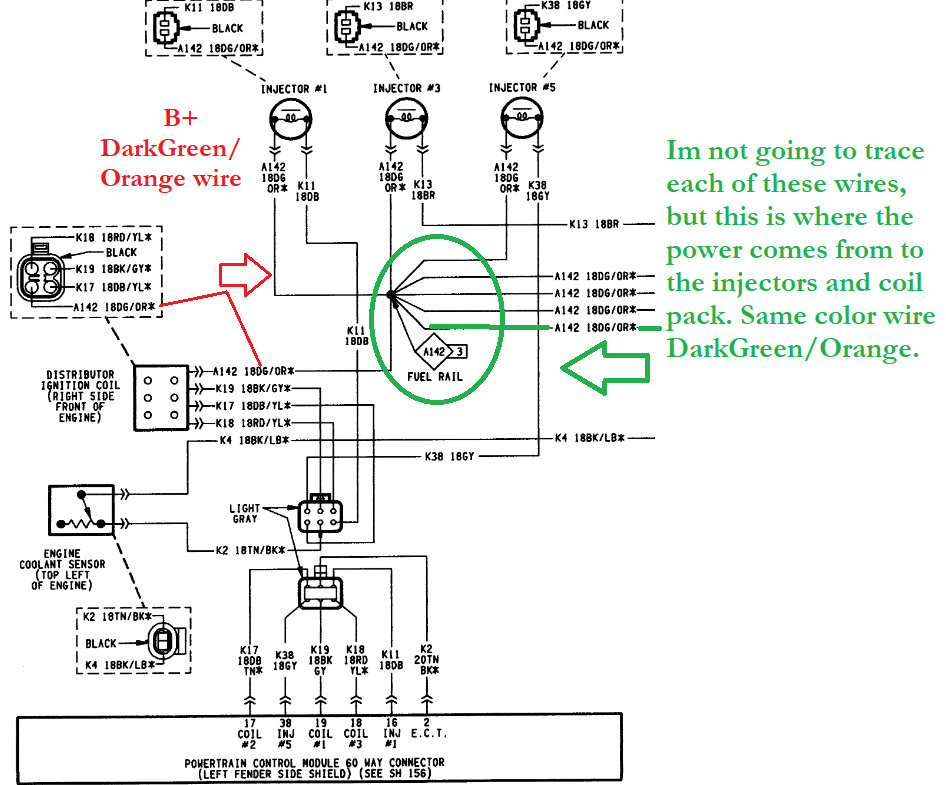

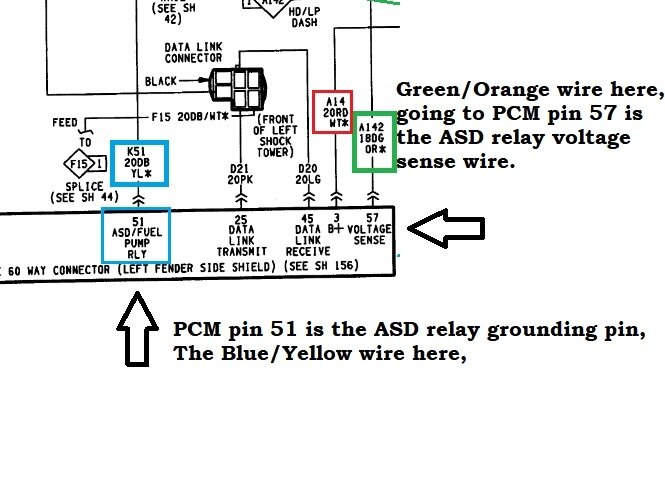

Pin 87 is where the power is going to exit the relay and head out to the injectors/coil etc. So those pins are the Load side. That should be the Green/Orange wire, So key On the relay should click and there should be 12v on the Green/orange wire (pin 87).

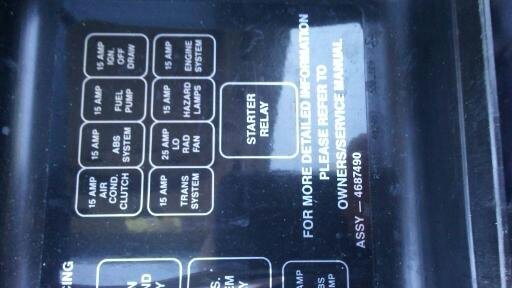

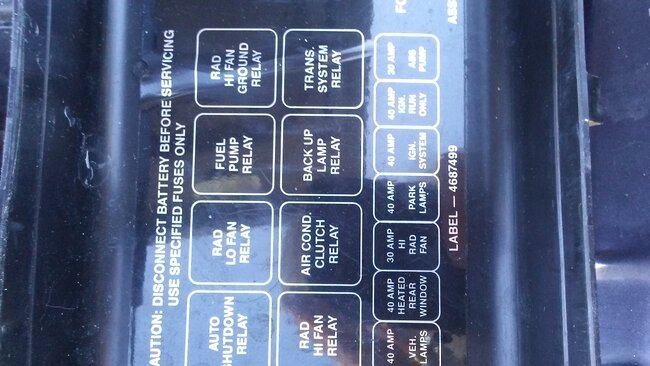

In the wiring diagrams they have these relays pins marked 29, 30, 31, 32 so thats useless here.

Right now all we know is that youre missing power to the coil and injectors so we need to solve that first.

There should also be a Blue/Yellow wire and a Blue/White, those should be the other 2 wires to the relay, One will have power, and the other goes to the PCM.

*(note here, the PCM is using the Green/Orange wire for its "Sense" going to pin 57 of the PCM, thats telling the PCM that power came through the relay. So it might be ok,

I think youre going to find a broken or very corroded connector somewhere. And there's voltage being lost there.

Images (Click to make bigger)

Monday, July 1st, 2024 AT 1:06 PM