Hi and welcome to 2CarPros.

If it is working properly, it isn't necessary to replace anything. As far as the flywheel, you will see marks on it, but that doesn't mean it's bad.

Now, if you want to replace the clutch, it's recommend to replace everything at once. To remove the transmission more than you have to isn't an easy job.

Here are the directions for clutch replacement. The attached pictures correlate with these directions.

___________________________

Clutch, Servicing

Vehicle Transmission and Drive-train Clutch Clutch Disc Service and Repair Procedures 5 & 6 Speed M/T 02M Clutch, Servicing

CLUTCH, SERVICING

Clutch, servicing

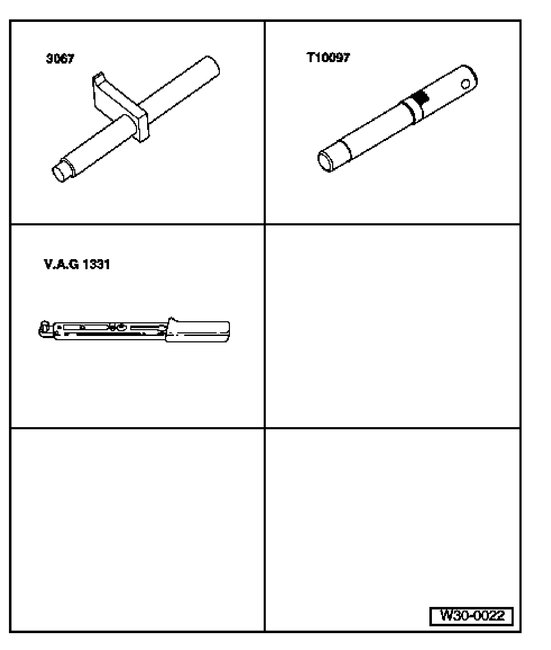

Special tools and equipment

3067 Counter-hold

T10097 Centralizing mandrel

VAG1331 Torque wrench or equivalent

(Transmission removed)

Note:

Before replacing the clutch and pressure plate note fault finding transmission No. 9 - Defects on the clutch and clutch mechanism

Replace clutch plates and pressure plates that have damaged or loose rivets

Select correct clutch plate and pressure plate according to parts list and engine code.

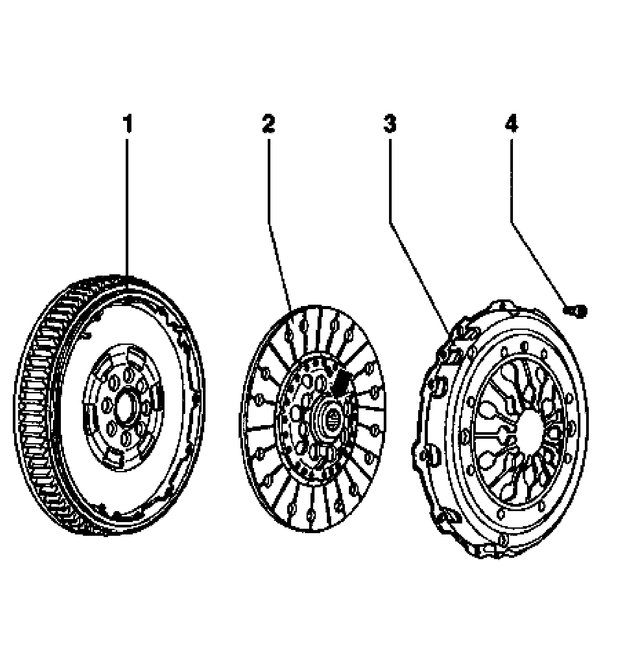

1 - Flywheel

2 - Clutch plate

Centering, Refer to Fig. 1

Lightly grease splines

Note: Clean input shaft splines and, on used clutch plates, the hub splines, remove corrosion and apply only a very thin coating of grease, Part No: G 000 100, to the input shaft splines. Then move clutch plate back and forth on the input shaft until the hub moves freely on the shaft. Excess grease must be removed.

3 - Pressure plate

Removing and installing, Refer to Fig. 1

Check ends of diaphragm spring, Refer to Fig. 2

Note: Pressure plates are protected against corrosion and greased. Only the contact surface may be cleaned, otherwise the service life of the clutch will be considerably reduced.

4 - Bolt Use Parts Supplier to check correct application

On two-part flywheel:

22 Nm

Always replace

On single piece flywheel:

20 Nm

Loosen and tighten gradually and diagonally

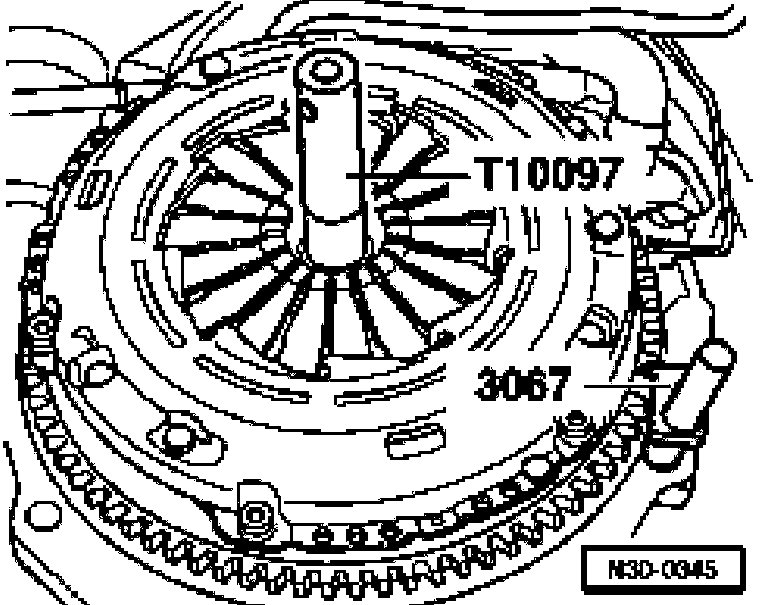

Fig. 1 Centering clutch plate with larger hub diameter and removing and installing pressure plate

Loosen and tighten bolts gradually and diagonally.

Reverse position of retainer 3067 when removing.

Note: Pressure plate contact surface and clutch plate must make full contact with flywheel. Tighten bolts diagonally and evenly to prevent damage to the centering holes in the pressure plate housing and the centering pins in the flywheel.

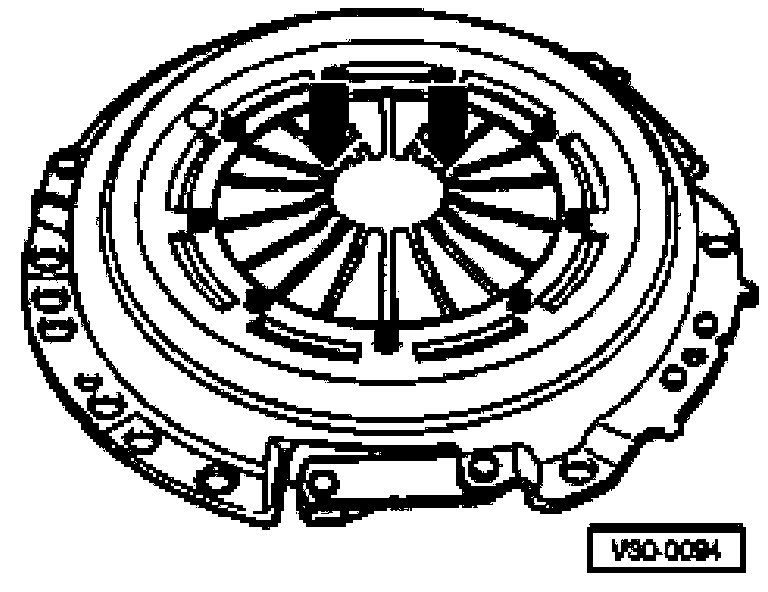

Fig. 2 Checking ends of diaphragm spring

Wear up to half the thickness of the diaphragm spring is permitted.

_________________________

Let me know if this helps.

Take care,

Joe

Images (Click to make bigger)

Friday, December 21st, 2018 AT 10:11 PM