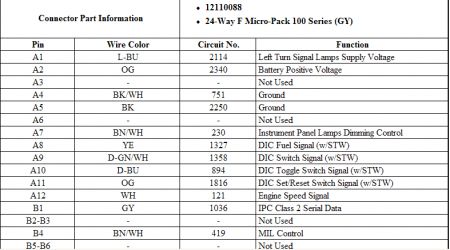

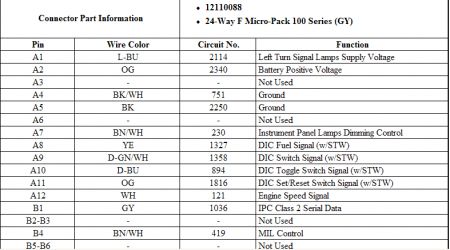

Probably in the cluster, starting point is Tech II scantool! Only thing you can check without it is the connector and pins on the cluster. Here's the layout, yellow is the fuel signal.

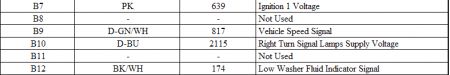

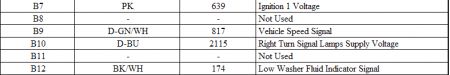

And also check this connector, Important!

Posted By: Administrator 1 Flag Post For Monitor Review

Shop: Mitchell 1 Admin

Date: 6/29/2007 3:37:12 PM

Models:

2004-2007 Buick Rainier

2002-2007 Chevrolet Trailblazer, Trailblazer EXT, Trailblazer SS

2002-2007 GMC Envoy, Envoy Denali, Envoy XL, Envoy XUV

2002-2004 Oldsmobile Bravada

2005-2007 Saab 97x

The following diagnosis might be helpful if the vehicle exhibits the symptom(s) described below.

Condition/Concern:

A vehicle may exhibit: 4WD inoperative, SIR lamp, erratic fuel gauge operation and/or a Service Stability Message. Possible DTCs are C0186, C0196, C0327, C0455, P0452, P0453, P0461, P0462, P0463, P0464 and or U1088. A possible cause of these symptoms is a loose connection or backed out terminal(s) at the C101 connector, a 38-way connector mounted along the under hood fuse block. This harness may be routed tightly around the UBEC that could induce any of the concerns listed.

Recommendation/Instructions:

All terminal connections should be checked in this connector for integrity. Female terminals should be inspected for pin drag and Male terminal should be fully seated in the body cavity of the connector. Be certain that no terminals are bent or damaged in any way. Re-route the harness to prevent future harness and/or connector strain.

Note: When servicing this connector special care should be made not to damage other terminals. Fully seat the connector squarely with both hands and then latch the locking portion of the connector (CPA). Do not use the lock mechanism on the connector to pull the connector halves together as this may cause terminals to bend or a poor connection.

Source: GM Preliminary Information Bulletin #PIT3208D - (06/19/2007)

Friday, April 3rd, 2009 AT 2:25 AM