Hello Rick

Okay, gonna go over a couple of things so we can brainstorm this together.

When you put the motor in, you didn't do anything to the valves - lifters???

You said it has compression - you took a reading at each cylinder?

You stated it had fuel; did you record the fuel pressure - Ignition on - engine off 40.5 to 47 psi?

If the car doesn't start within about 2 seconds the ECM turns the pump off.

Here is some info on the fuel relay

When the key is first turned "ON," without the engine running, the ECM will turn the fuel pump "ON" for two seconds. This builds up the fuel pressure quickly. If the engine is not started within two seconds, The ECM will shut the fuel pump "OFF" and wait until reference pulses are present. As soon as the engine is cranked, the ECM turns the relay "ON" and runs the fuel pump.

As a back up system to the fuel pump relay, the fuel pump can also be turned "ON" by the oil pressure switch. The oil pressure switch is a normally open switch which closes when oil pressure reaches about 28 kPa (4 psi). If the fuel pump relay fails, the oil pressure switch will run the fuel pump.

An inoperative fuel pump relay can result in long cranking times, particularly if the engine is cold, and this should set Code 54.

An inoperative fuel pump would cause a no start condition. A fuel pump which does not provide enough pressure can result in poor performance.

I would check the relay if you have good pressure and you know you have spark. . .a good strong blue popping spark when cranking.

Here is some info on the cold start injector to check.

You have a good filter installed?

See if what I have provided helps at all. I would check fuses, compression; make sure there is good spark, good fuel pressure, the fuel relay, coolant sensor, cold start valve.

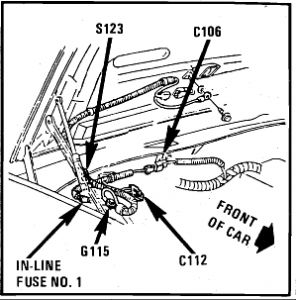

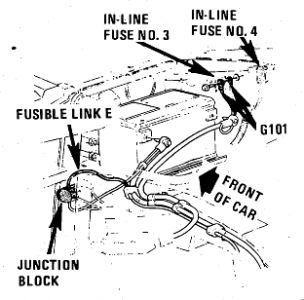

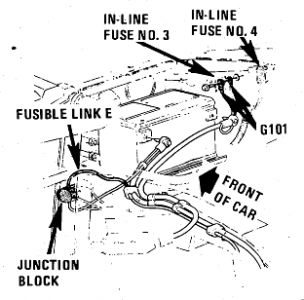

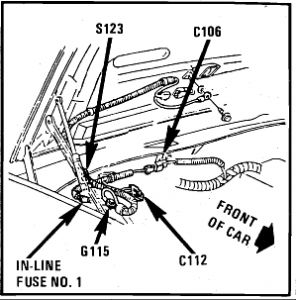

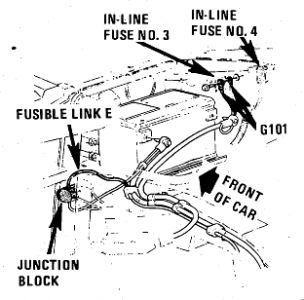

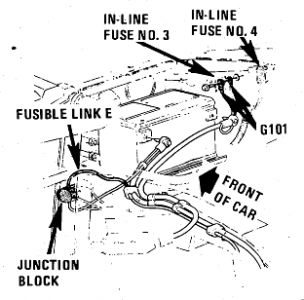

I have attached inline fuse info

Let me know if this helps.

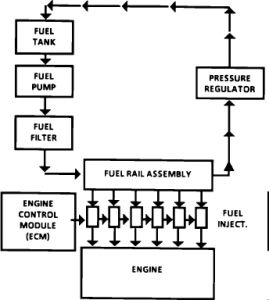

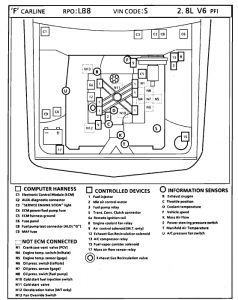

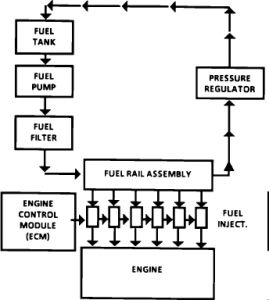

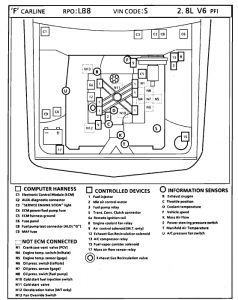

The fuel metering system consists of the following components:

Fuel pump electrical circuit.

Fuel supply components, including:

Fuel lines and pipes.

Fuel pump.

Fuel tank.

Fuel rail assembly, including:

Fuel injectors.

Fuel pressure regulator.

Cold start valve.

Throttle body assembly, including:

Idle air control valve.

Throttle position sensor.

BASIC SYSTEM OPERATION:

The fuel supply system begins with gasoline in the fuel tank. An electric fuel pump, located in the fuel tank with the fuel level gauge sending unit, pumps fuel to the fuel rail through an in-line filter. The pump is designed to supply fuel at a pressure above the pressure needed by the injectors. A pressure regulator located on the fuel rail keeps the fuel available to the injectors at a constant pressure. The unused fuel is returned to the fuel tank by a separate line.

MODES OF OPERATION:

The ECM uses voltage inputs from several sensors to determine how much fuel to give the engine. The fuel is delivered under several conditions, called "Modes." All modes are controlled by the ECM, and are described below.

Starting Mode:

When the ignition is first turned "ON", the Electronic Control Module (ECM) turns "ON" the fuel pump relay for two seconds, allowing the fuel pump to build up system pressure. If the engine is immediately started, the fuel pump will continue to operate. If the key is left in the "ON" position, but the engine is not started, the ECM will turn the pump "OFF." Fuel delivery in the "Starting" mode is split between the port fuel injectors, which are ECM controlled, and the cold start valve assembly, which is controlled by a coolant temperature sensitive switch.

Fuel delivery from the port injectors (which deliver fuel in all operating modes) is controlled by changing the amount of time the injectors are turned on or "pulsed" by the ECM. The ECM checks the coolant temperature sensor, throttle position sensor, and determines the proper air/fuel ratio for starting. This ranges from 1.5:1 at -36 °C (-33 °F) to 14.7:1 at 94 °C (201 °F).

Clear Flood Mode:

If the engine floods, it may be cleared by pushing the accelerator pedal down all the way. The ECM then will completely turn off the fuel. The ECM holds this injector rate as long as the throttle stays wide open, and the engine speed is below approximately 637 rpm. If the throttle position becomes less than approximately 75%, the ECM returns to the starting mode.

Run Mode:

The run mode has two conditions, called "Open Loop" and "Closed Loop".

Open Loop:

When the engine is first started, and engine speed is above 637 rpm, the system goes into "Open Loop" operation. In "Open Loop", the ECM ignores the signal from the Oxygen sensor, and calculates the air/fuel ratio based on inputs from the coolant temperature and manifold pressure (MAP) sensors.

The system will stay in "Open Loop" until the following conditions are met:

The Oxygen sensor has a varying voltage output, showing that it is hot enough to operate properly. (This depends on temperature)

The Coolant temperature is above a specified temperature.

A specified amount of time has elapsed after starting the engine.

Closed Loop:

The specified operating conditions vary with different engines, and are stored in the memory calibration module (Mem-Cal). When these conditions are met, the system goes into "Closed Loop" operation. In "Closed Loop," the ECM calculates the air/fuel ratio (injector on-time) based on the signal from the Oxygen sensor. This allows the air/fuel ratio to stay very close to 14.7:1.

Acceleration Mode:

The ECM responds to rapid changes in throttle position and air flow, and provides extra fuel.

Deceleration Mode:

The ECM responds to changes in throttle position and air flow, and reduces the amount of fuel. When deceleration is very fast, the ECM can cut off fuel completely for short periods.

Battery Correction Mode:

When battery voltage is low, the ECM can compensate for the weak spark delivered by the integrated direct ignition (IDI) module by:

Increasing the injector pulse width.

Increasing the idle speed.

Increasing the ignition dwell time.

Fuel Cut-Off Mode:

No fuel is delivered by the injector when the ignition is "OFF." This prevents dieseling. Also, fuel is not delivered if no reference pulses are received from the ignition module, which means the engine is not running. This prevents flooding.

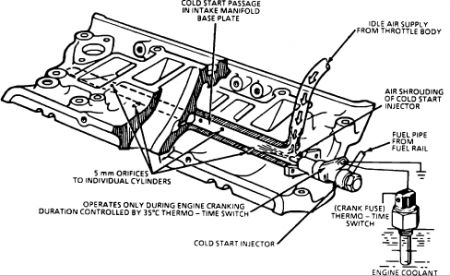

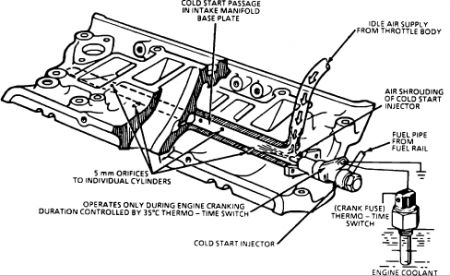

Cold Start Injector

DESCRIPTION:

The Cold Start Valve is a non-ECM controlled solenoid operated valve used to provide fuel during the "Starting Mode". It is mounted to the intake manifold and is controlled by a coolant temperature switch. The cold start valve is different from a port injector in that it is not pulsed, instead, it is either on or off.

Fuel from the cold start valve is sprayed into the passage in the intake manifold where it mixes with air from the Idle Air Control (IAC) Valve, and is directed through branch passages to the cylinder ports. By injecting the fuel further back from the cylinders, and adding air to the fuel, the mixture is highly vaporized before entering the cylinders and provides a more combustable mixture for improved cold starting.

OPERATION:

Fuel delivery from the cold start valve occurs only during cranking, and only when the engine coolant temperature is below 35 °C (95 °F). The cold start circuit receives it's power directly from the starter solenoid, and is protected by the crank fuse. The cold start fuel injection switch (thermo-time switch) provides the ground path for the circuit. It is a bimetal switch which opens the circuit at a specified coolant temperature. The bimetal is also heated by the winding in the switch which would allow the valve to stay "ON" 8 seconds at -20 °C or below. The time the switch stays closed varies inversely with coolant temperature. In other words, as the coolant temperature goes up the maximum cold start valve "ON" time goes down.

Sunday, November 9th, 2008 AT 8:22 PM