Lots of dandy information here so just let me add a few comments I thought of. First of all, no instructor will ever teach that an alignment should leave the car drifting to the right. The thought is that if you fall asleep at the wheel, you'll drift into the ditch instead of oncoming traffic. To me that is an excuse for why someone didn't align my car properly. Experience here plays a much bigger role than learning in a school because you have to become familiar with the stretch of road you use for test-driving customers' cars. I was the alignment specialist at a very nice Chrysler dealership through all of the '90s, and for those ten years I always followed the same route and knew how the cars should act. I knew they should pull a lot to the left in one spot and that they'd drift a little to the right in another spot. If that's what the car did, I knew they owner wouldn't be back with a pulling complaint. Without that experience the only thing you have to go on is the numbers on the alignment computer screen. If the car pulls when you're done, you don't know if it's the road, the tires, the brakes, or you messed up the alignment.

As I mentioned earlier, I watched a coworker align two '70s cars, a Lincoln Continental and a Chevy Impala, with a carpenter's level, and the stupid idiot, (my friend), got good results. That can work for a lot of cars but it's very easy to have no pull and a straight steering wheel when both tires are tipped in or out too much on top. As long as they're equal, those two things will be okay but there can be tire wear on the inner or outer edges that will take a long time to show up.

Getting back to that drift to the right, that WILL occur on most roads if you set "camber" exactly equal on both sides. That's the tip in or out on top of the wheel / tire. I can't remember the specs for every car but a huge percentage of GM front-wheel-drive cars call for 0.00 degrees, and that's what you would get with a carpenter's square. Beyond that, we always adjust the left wheel to tip out on top a fuzz more than the right one. Camber makes a tire want to steer or pull in the direction it's leaning, so it has to be right for proper tire wear, and it has to be equal to go straight. The reason for making the left wheel higher is to offset "road crown". All roads slant to the right so rain will run off. When camber is exactly equal on both sides, the car will drift to the right because of that road crown. That adds to why many people think it's normal to have that drift. I found that every Chrysler front-wheel-drive model needed exactly 0.06 degrees more camber on the left to make them go straight. You'll never see that with a carpenter's level. Besides the fact the tire bulges out on the bottom from the car's weight, that tiny amount would equal about 1/64" at the top part of the sidewall. If you tried to make that adjustment sitting on the ground instead of slip plates, Chryslers and most GMs are adjusted at the two lower strut mounting bolts like saturntech9 said. That brings the top 2/3 of the wheel and tire out, (if that's the way you're adjusting it), but since the lower ball joint becomes the pivot point in effect, the bottom 1/3 moves in as the wheel moves. The tire tread is going to stick to the road and the sidewalls will just flex. You will only see the results of that change with a level or square at the top of the tire, not at the bottom, so you'll only see half of what really took place. It would be more accurate to place the level between the upper and lower edges of the wheel, not on the sidewalls of the tire. That is why we need slip plates on the alignment rack, ... So the bottom of the tire can slide around freely.

The only thing I would feel fairly confident on after using a square is you got both wheels set the same. I learned over time that most GM front-wheel-drive cars are quite forgiving of road crown. Where Chryslers need 0.06 degree camber pull to the left, GMs didn't need any extra camber to go straight.

By the way, the reason I jumped on the cross member at first is you said there was engine work, clutch work, and now the steering rack. Any of those are potential reasons to remove the cross member, and by far the most common complaint after that is miserable steering control and the steering wheel shifts position as the car goes up and down over bumps.

"Caster" that saturntech9 mentioned is the angle of an imaginary line drawn between the two steering pivot points as you look from the side of the car. In your case that's the lower ball joint and the upper strut mount. On older vehicles that was the lower and upper ball joints. Caster is easiest to visualize if you look at the rake of a bicycle or motorcycle fork. It tilts to the rear on top. That's positive caster and is what makes it possible to ride no-handed. Weight on the assembly makes the tire squirt out straight ahead. On cars it makes each wheel want to turn toward the center. They offset each other when the steering linkage is connected between them. Caster has very little effect on tire wear but it mainly affects pulling to one side and steering wheel return after cornering. Big heavy cars and trucks used to be easy to steer up to the late '50s and early '60s because they used negative caster, but steering wander became a problem when higher speeds on the highways became common. Making the caster positive and higher, in the area of 3 degrees, got rid of the wander and made the vehicles more stable, but it made it a lot harder to turn the steering wheel. That's why they added power steering. The biggest thing is that it must be the same on each side. Positive caster makes the left wheel want to turn to the right just from having the car's weight on it, and the right wheel wants to turn to the left. When you connect the steering linkage between them, they balance each other out and the car goes straight. When caster is higher on one wheel, that one wants to turn toward the center of the car harder than the other one and that results in a pull. Here's the clinker though. On 99 percent of front-wheel-drive cars, unequal caster results in no noticeable pull. I've never gotten an acceptable answer although it might be related to my next comment, but on rear-wheel-drive cars caster has exactly half the effect on pull as camber. '60s and '70s Chryslers called for 1/2 degree camber on the left and they specified 1/4 degree on the right, knowing that was what was needed to offset road crown. GMs often called for around 3/4 degree and we also put in that 1/4 degree pull to the left. However, if you wanted to, you could achieve the exact same offset to road crown by adjusting in 1/2 degree more caster on the right. These were big, heavy cars, but that tiny 1/4 degree was very noticeable when it was missing. I had one front-wheel-drive car in the mid '90s that had 3.0 degrees difference in caster after crash damage was repaired. I sent it back to the body shop, but they assured me nothing was wrong. Surprisingly it did go perfectly straight after the alignment. Caster wasn't adjustable and it didn't cause a problem. That's why front-wheel-drive cars don't have caster adjustments. The few older imports that did only had two settings depending on how you rotated the upper strut mount. Even they knew it wasn't critical. As far as moving the upper strut mount forward or backward, I don't remember ever finding it necessary to attempt that, but on most cars, shifting the strut could lead to the coil spring rubbing on the inner fender. One notable exception is the Camaro / Firebird that has caster adjustment capabilities built in, but those are rear-wheel-drive.

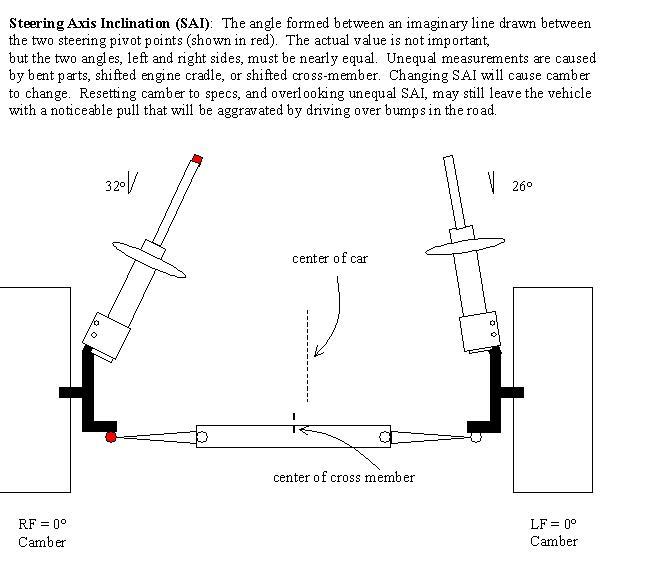

Your comment about a brake pull got my attention too because that is no longer a reliable indicator of anything due to design changes in the suspension geometry. Older cars had about 70 percent of the weight on the two front tires. Front-wheel-drive models have about 80 percent on the front. We used to have the brake hydraulic system split so one half ran the front brakes and the other half ran the rears. With so much weight on the front, if you'd pop a brake line and only had the rear brakes working, the car would go and go until they found you in the next county. To address that, all front-wheel-drive vehicles I'm familiar with use a "split-diagonal" hydraulic system. Each front wheel is on a different system so if you pop a line you'll still have 50 percent of your braking power. The left front and the right rear wheels are on the same system. Now the issue is if you pop a line, only one front brake will work. On older cars that would result in a real hard brake pull to that side. I drove a car that a guy blocked the leaking line to one front wheel. It just about tore the steering wheel out of your hands when you hit the brakes. The reason that doesn't happen on front-wheel-drive cars is the engineers changed a non-adjustable alignment angle called "scrub radius". In my pretty artwork up above, I described SAI as the line through the upper and lower steering pivots. If you extend that line down to the road, it used to intersect the tire tread right in the middle. The effect of that was to make the left half of the tread stick to the road, (or "scrub), and try to turn the entire tire to the left. The right half of the tread wanted to turn the tire to the right, and the two forces balanced each other out. By the way, altering ride height, installing taller tires, or installing wheels with a deeper offset, like we liked to do in the '70s, changes scrub radius. Now that we're smarter we understand the ramifications of doing that, ... So we don't.

On the front-wheel-drive cars scrub radius is changed so that imaginary line intersects the road further outside on the tire tread. Now, perhaps 3/4 of the tread wants to pull toward the center of the car and only 1/4 wants to pull away from it. The two tires still offset each other equally and the car goes straight, but when you have a brake hydraulic failure on, ... Let's say the left side, when you hit the brakes, the right brake will make that tire want to pull back which turns it to the right. With 3/4 of the tread now pulling to the left, that is enough to offset that and the car stops in a straight line without having to do anything with the steering wheel. I've found that on most Chryslers you won't see anything in the steering wheel but you'll of course have a mushy brake pedal from the leak. On almost all other cars you'll see a very tiny wobble in the steering wheel when you hit the brakes but the car will still stop in a straight line. That barely perceptible wobble will go unnoticed by almost all car owners but it's a valuable clue, especially on GM cars. They have a valve in the brake master cylinder that shifts position to block off the two ports feeding the hydraulic system with a leak. You don't lose all the brake fluid that way, which is nice, but other than the red "brake" warning light on the dash, you won't have any other symptoms. People have been known to drive like that for months staring at that light and not realizing they only have half their brakes. The steering wheel wobble is the clue.

The other somewhat common complaint is new brake pads wear out real quickly on one side but look like new on the other side. People who understand how brakes work assume one caliper is sticking and not releasing, but in reality it is the only one that is working and has to do all the stopping. The warning light will usually not be on and you won't really feel the loss in braking power.

Sorry to get so far off the subject, but that is why brake pulls act differently than you would expect. To illustrate scrub radius further, my daily driver is an old rusty trusty '88 Grand Caravan. It's getting so bad that I've had to weld up holes rusted right through the wheels. Right now I have one leaking so badly I have to pump that tire up every morning. It drives perfectly straight, but when I come home late at night the left tire is down to about 20 pounds, which is real easy to see, and it makes the van pull hard to the right. All our experience and common sense says a vehicle should pull toward the flat tire but in this case it pulls the other way. That tire is scrubbing much harder on the road surface than the right tire, and 3/4 of that tread is pulling to the right. Try explaining that to a knowledgeable customer complaining of a pull to the right being caused by the left tire.

As for your string to adjust front toe, we used to do that on race cars where it wasn't real critical on short tracks, but you have to remember that is setting "total toe" which only addresses tire wear. If both wheels are misadjusted to the same direction, left or right, an equal amount, total toe will still be correct but the car will steer that way. To make up for that you have to turn the steering wheel the other way to bring the wheels back to straight ahead. That's the complicated way of saying the steering wheel will be off-center. With rack and pinion steering it's easy to know which way to turn a tie rod to turn the wheel, and you can turn each one an equal amount in opposite directions, (lengthen one, shorten the other), to keep total toe the same but center the steering wheel. On the alignment computer however, most cars call for 1/16" total toe-in, plus or minus 1/16", and to get that 1/16" of change requires turning a tie rod about 1/32" of a revolution. I used to put chalk lines on them so I could see how far I was turning each one, and I learned it was impossible to set them precisely by doing it freehand. You need the precision of the alignment computer to get it right.

I had to change the first outer tie rod end at 200,000 miles, and being the smart guy I thought I was, since I was just replacing one part, I drove the van to see where the steering wheel was, then stopped and adjusted that same tie rod until the steering wheel was straight again. Logic says if total toe was correct before and the steering wheel was straight, if it's straight now, total toe should be right again. Guess again. There was some feather-edging that showed up a couple of months later. Of course, being the smart fellow I REALLY am, I knew how to "read" that pattern and know which way to tweak the adjustment. The point is the tire wear will show up eventually before you'll see a crooked steering wheel when toe is off just a little.

Sorry for getting so long-winded. As a former instructor, I can't help myself when someone takes an interest in how their car works and wants to learn more. That's why a lot of us are here.

Wednesday, October 23rd, 2013 AT 2:19 AM