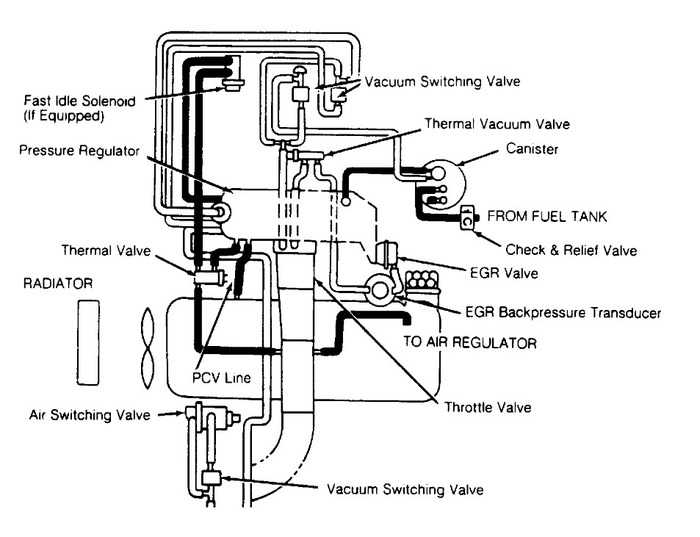

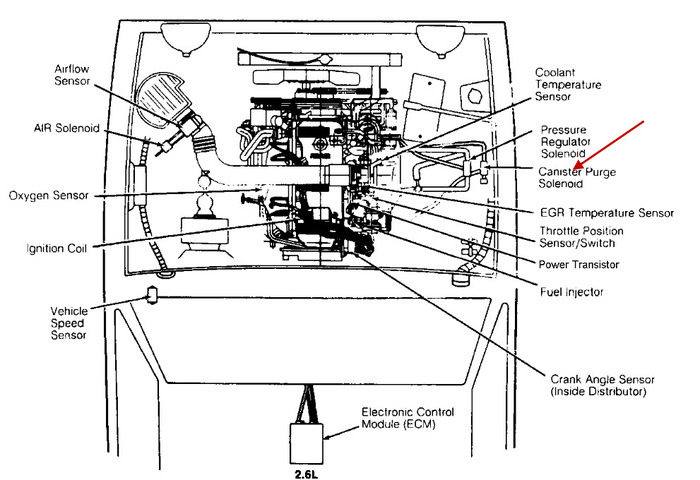

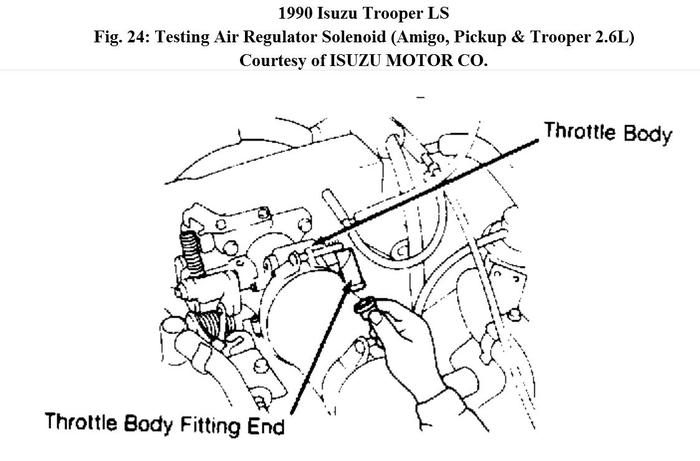

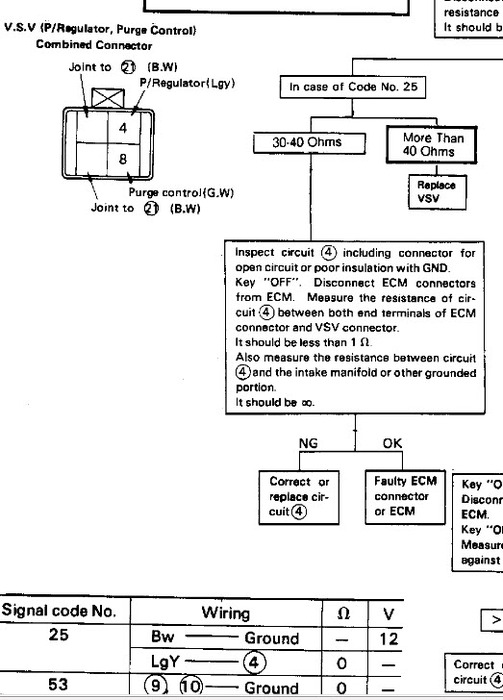

Idle is set at 950, the throttle sensor is correctly adjusted. There is no water in the fuel. I have replaced cracked vacuum lines and the EGR valve. I have lubricated the Air regulator. Fast idle does not kick in when I turn on the A/C, for that matter the core fan does not come on either. I pinching off the hose to the fuel regulator has no effect. When you tac up the rpms it back fires. I would say that the system was running on failsafe mode but for the code 12. Fuel pump relay is good. I have tried swapping out the ECM but no change idle. I haven't actually RR the Air Regulator just read on line you can put penetrating oil down the breather tube to free it up. Hope this is enough info.

We live in Africa so swapping out parts willy nilly is not an option. When I order parts they can take as long as three months to get here. I have a 1990/1991 Isuzu Workshop Manual but I am a carpenter not mechanic and non of the locals know anything more than I.

Saturday, September 29th, 2012 AT 3:05 PM