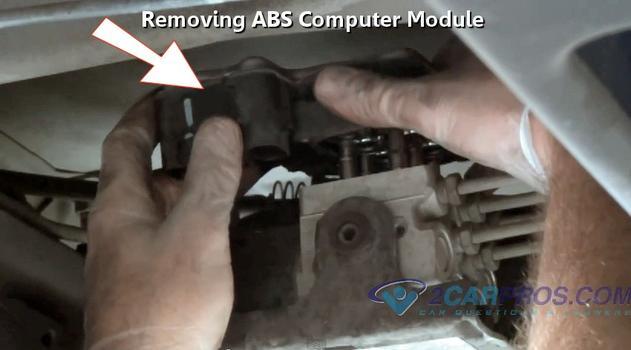

A wheel speed sensor is designed to provide feedback information to the traction control and ABS computer to help monitor tire rotational speed. This guide will help walk you through the replacement procedure which will be a little different for each application.

Supplies Needed

- Tool Set

- Replacement Wheel Speed Sensor

- Floor jack

- Gloves and protective eyewear

- Shop towel

- Lug wrench

Park the car on level ground with the transmission in park, the emergency brake set with the engine off, block the wheels so it is does not roll when lifted. Use the lug wrench to break lose the wheel lugs one turn before using a hydraulic jack to remove the tire. Note: Some wheel speed sensors can be removed separately, while other sensor designs are integrated into the wheel bearing hub assembly, which needs to be replaced as a unit.

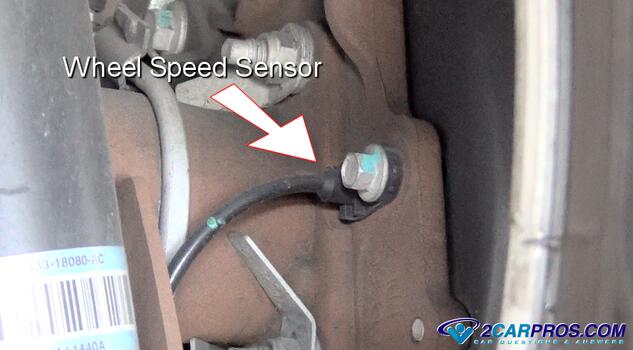

1. The wheel speed sensor is located near the tire to sense the rotation and give feedback data to the ABS/Traction Control computer, locate the sensor lead and disconnect it. The location for this connector will vary, on rare occasions it will be inside the car as the example below, so you might need to remove interior panels or wheel well plastics for access.

2. Locate the wire lead support brackets which are usually held on by a small bolt or clip. Simply remove the bolts or undo the clips to free the sensor lead, there may be more than one.

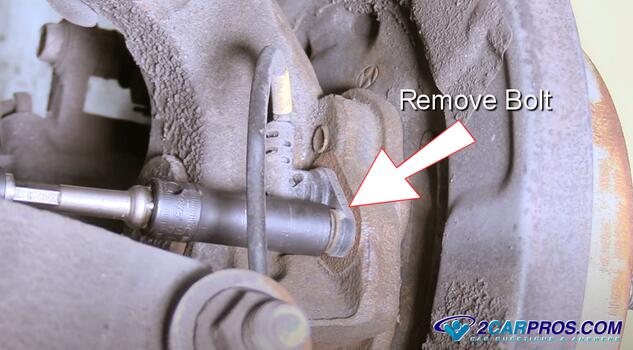

3. Locate the wheel speed sensor near the spindle or backing plate for the brake rotor and remove the mounting bolt which is usually 10mm.

4. Gently grasp and pull on the sensor body to remove it from its location, it can be a little stuck because an O ring is used to help seal the sensor. Use a flashlight to peer into the sensor port, slowly spin the tire to check the condition of the stator ring teeth.

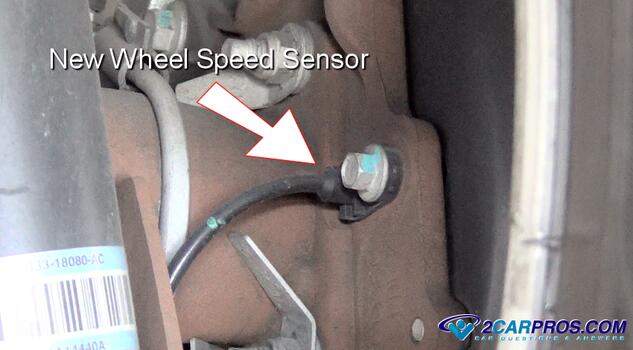

5. Match the new wheel speed sensor to the old unit to ensure proper installing and operation. Confirm the electrical connector is clean from dirt and grease before reassembly. Once the sensor has been replaced the ABS warning light should go out without resetting or clearing the codes in most cases. Some older systems might require a scan tool to reset the system, but this not typical.

Watch the Video!

Please watch this video of the job being done to glean additional helpful information.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel.