Hi,

The first thing to do is check and confirm there is proper fuel pressure and ignition spark to the plugs. Take a look through these three links:

https://www.2carpros.com/articles/car-cranks-but-wont-start

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

https://www.2carpros.com/articles/how-to-test-an-ignition-system

The fastest thing to do is this. See if it starts using starting fluid and then stalls. If it does, then we know it is a fuel-related issue. If it doesn't, then it's likely ignition-related issues.

As I was reading through your post, the first thing that came to mind was a plugged catalytic converter. Have you ever checked for that condition? It will cause a power loss as you mentioned.

https://www.2carpros.com/articles/how-to-test-a-catalytic-converter

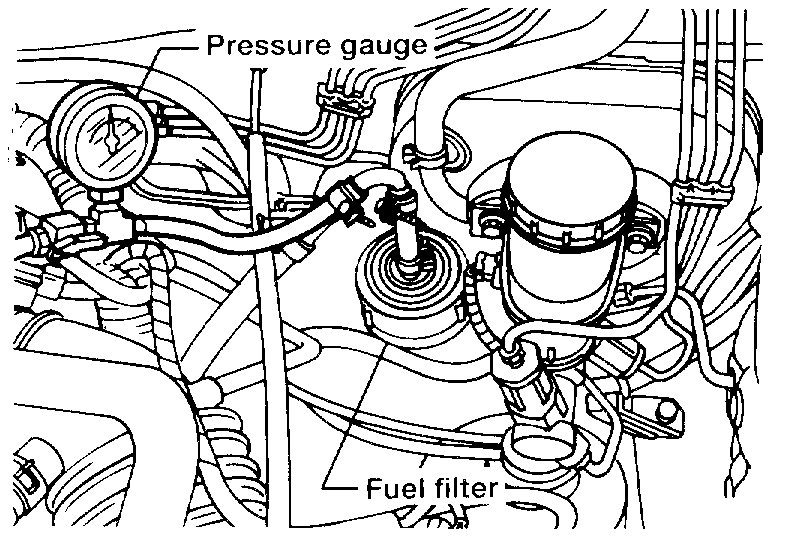

Here are directions specific to your vehicle for testing fuel pressure. The manufacturer's specs are included. Also, the picture below correlates with the directions.

________________________________

1998 Nissan-Datsun Sentra GLE L4-1597cc 1.6L DOHC MFI (GA16DE)

Fuel Pressure Test

Vehicle Powertrain Management Fuel Delivery and Air Induction Fuel Pump Fuel Pressure Testing and Inspection Component Tests and General Diagnostics Fuel Pressure Test

FUEL PRESSURE TEST

See pic 1 below

- When reconnecting fuel line, always use new clamps.

- Make sure that clamp screw does not contact adjacent parts.

- Use a torque driver to tighten clamps.

- Use Pressure Gauge to check fuel pressure.

- Do not perform fuel pressure check with system operating. Fuel pressure gauge may indicate false readings.

1. Release fuel pressure to zero.

2. Disconnect fuel hose between fuel filter and fuel tube (engine side).

3. Install pressure gauge between fuel filter and fuel tube.

4. Start engine and check for fuel leakage.

5. Read the indication of fuel pressure gauge.

At idling:

With vacuum hose connected Approximately 235 kPa (2.4 kg/sq.cm, 34 psi)

With vacuum hose disconnected Approximately 294 kPa (3.0 kg/sq.cm, 43 psi)

If results are unsatisfactory, perform Fuel Pressure Regulator Check.

________________________________

Let me know what you find or if you have other questions.

Take care and God Bless,

Joe

Image (Click to make bigger)

SPONSORED LINKS

Tuesday, February 23rd, 2021 AT 7:38 PM