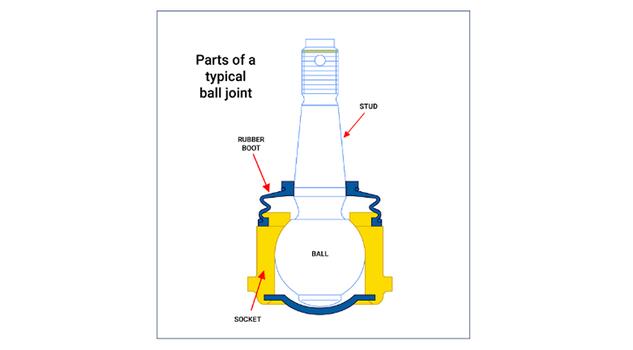

A ball joint is used to act as a universal swivel joint that connects the upper or lower control arms to the spindle which is where the axle bearing and wheel is supported. This joint is also responsible for allowing the steering to work as it is the bottom part of the pivot for the spindle and tie rod end. Constructed of a metal housing with a spherical metal ball, the ball joint is designed with the threaded stud attached at one end. This ball joint stud is designed with a slight taper which will lock into a tapered hole which offers a measure of strength when attaching the ball join to the spindle.

The ball is trapped inside the housing with enough clearance to move freely without play. Grease is used to lubricant the joint which may have a Zirk fitting that is used to refill the joint at regular service intervals. Most cars today have non-serviceable joints which are equipped with enough grease to last the duration of the ball joints' usability.

To replace or perform repairs on or near the ball joint such as replacing a control arm or a CV axle the ball joint will need to be undone which means taking the nut off of the joint and applying pressure while striking the spindle or control arm bulkhead with a hammer. Some ball joints have a cotter pin which is used as a safety device to keep the nut from coming off and the joint coming undone. Other designs have a self locking nut that doesn't require a cotter pin.

The most difficult part of removing any ball joint is disconnecting the taper fit stud at the end of the joint. Some ball joints are made into the lower or upper control arm while in other applications the joint can be unbolted separately. It is strongly suggested to have the car aligned after replacing a ball joint.

What Goes Wrong?

When the ball joint wears due to usage and the normal travel of steering and suspension parts the joint will have excessive play that will cause problems such as allowing the steering wheel to shake while driving and making popping and clicking noises as the car is being driven and going over bumps. Ball joint wear can also contribute to irregular tire wear.

How Much Does It Cost?

A ball joint without a control arm attached will run between $25.00 and $46.00 (US) each on Amazon. If the ball joint is not serviced separately and is included in the control arm you can expect to pay between $66.00 and $130.00 for each arm. The labor to replace a ball joint with the control arm will be between $160.00 and $280.00 depending on the manufacturer. To replace the ball joint by itself will run about the same for labor.

Credits

This guide knowledge base was created by the 2CarPros Team, and by Ken Lavacot: Automobile repair shop owner and certified master automobile technician of over 30 years. If you have question or need help please ask one of our experts we are happy to help. Please visit our 2CarPros YouTube Channel.