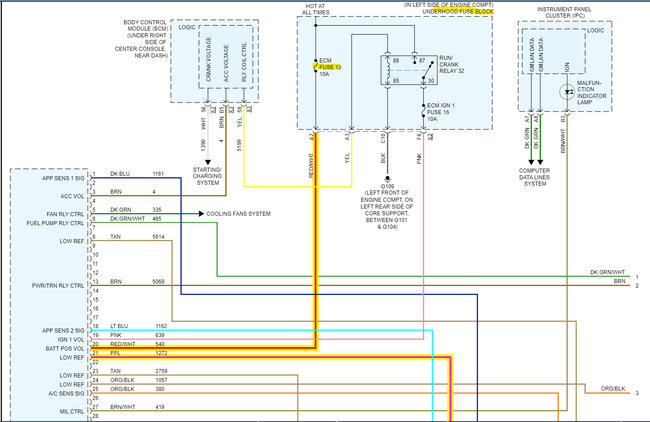

Hello Sean, the post was most likely moved or removed because your topic/issue should have been started in a question/post of its own. But wires overheat due to high resistance in the circuit, it may be that the pin in the ECM connector is spread apart and not making good contact with the ECM pins. That would be a location where the lack of a solid connection would cause it to get hot, or the ground itself is not good.

I wouldn't replace it with a high gauge wire. The wiring harness is engineered to carry the necessary current. If wires are melting, it's because of a problem that needs to be addressed.

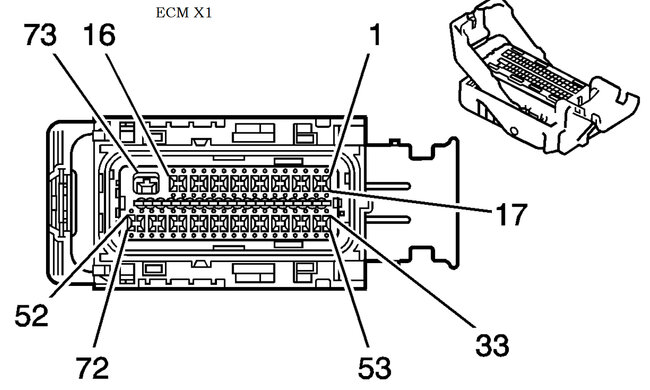

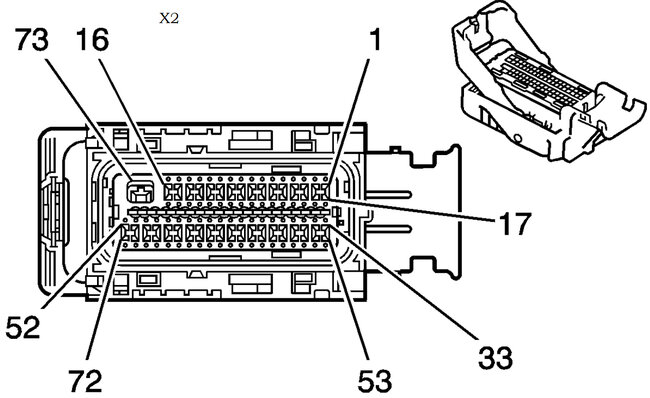

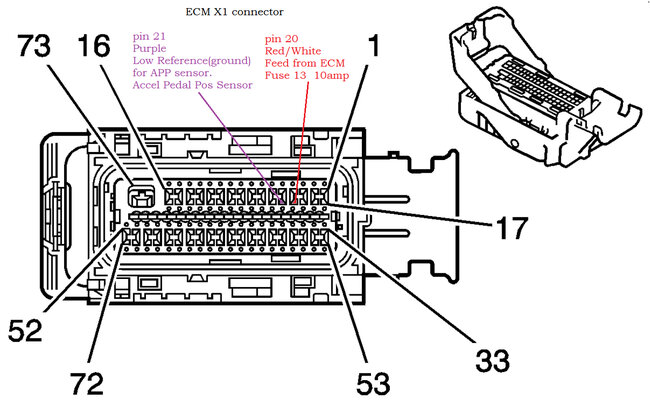

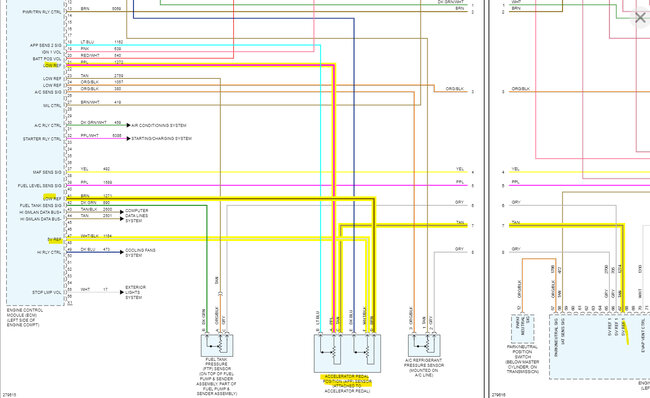

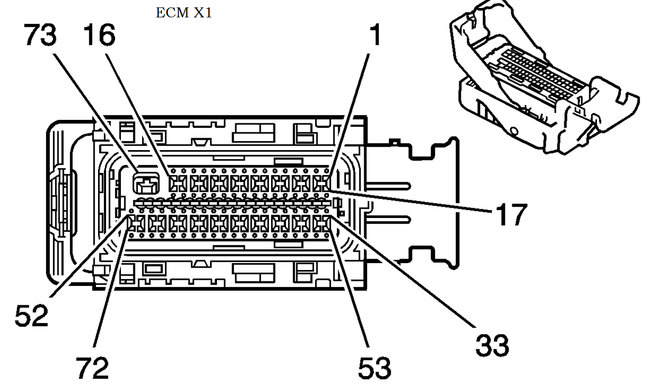

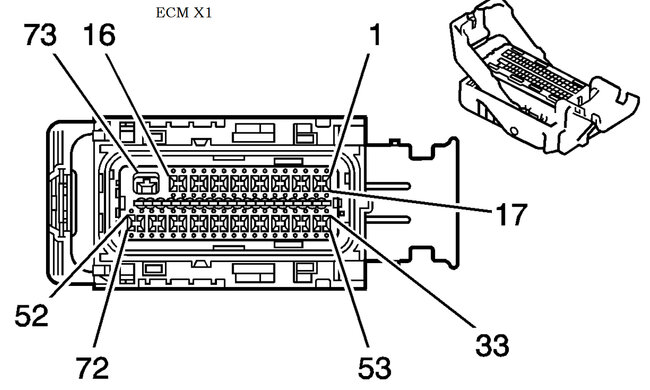

You need to check the pin tension inside the ECM connector first, use a pin that is slightly smaller than the one on the ECM side of the connection, and make sure there is good drag on the pin inside the harness side of the connector.

When these connectors are unplugged and plugged back in over the years or even just because its a ground or power wire, they carry more current than a sensor wire for example, so they heat up and cool down over many years, expanding and contracting, this can also cause them to end up with spread connector pins.

So, check the pin tension first. To actually de-pin the connector you will need to remove the connector's cover on the back if there is one, and from the back side there is a tab that is holding the pin into the connector, they are snap in tabs, and not easy to see. Use a bright flashlight to look into the back of the connector, the tab will be either on the top or bottom of the wire pin. These are small pins, probably only 2mm or so, you have to be very careful when trying to get the tab up so the pin will come out, don't force it at all, the wire should come right out when the tab is pulled up. I use a very small flat screwdriver, something like what is used for a pair of glasses screw.

They sell kits of different sizes for automotive connector pin removal tools for this.

Search YouTube for "automotive ECM pin removal method" and you will come up with many videos that show how to do it, because you don't want to damage the connector or the pin will never make good contact again.

You should load test that wire as well with a higher amperage test light such as a turn signal bulb or head lamp bulb. With the ECM connector unplugged use that pin as the ground for the bulb and B+ to power it, only do this test for a second or two, just to see if the circuit can carry current. Something else you can do during the load test is have a multimeter setup on DC volts going from that same pin to battery negative, this is a voltage drop test while load testing the wire.

It will tell you if there is excessive voltage drop from the ECM ground to battery negative terminal. You should see as close to 0volts as possible, there will be some voltage drop, but not much.

Hope this helps, in the future, start a new question/thread and someone will help you, that way the question won't be moved or removed on you.

Tuesday, April 15th, 2025 AT 12:35 PM