Wow. Excellent process of elimination. Plus the paper on the tailpipe shows you are "old school." So for the benefit of those that are reading this that don't know that trick, it is to test for a valve issue on the exhaust side.

If the paper is pulled into the tailpipe then you have a valve hanging open and the suction of the stroke will pull the paper in.

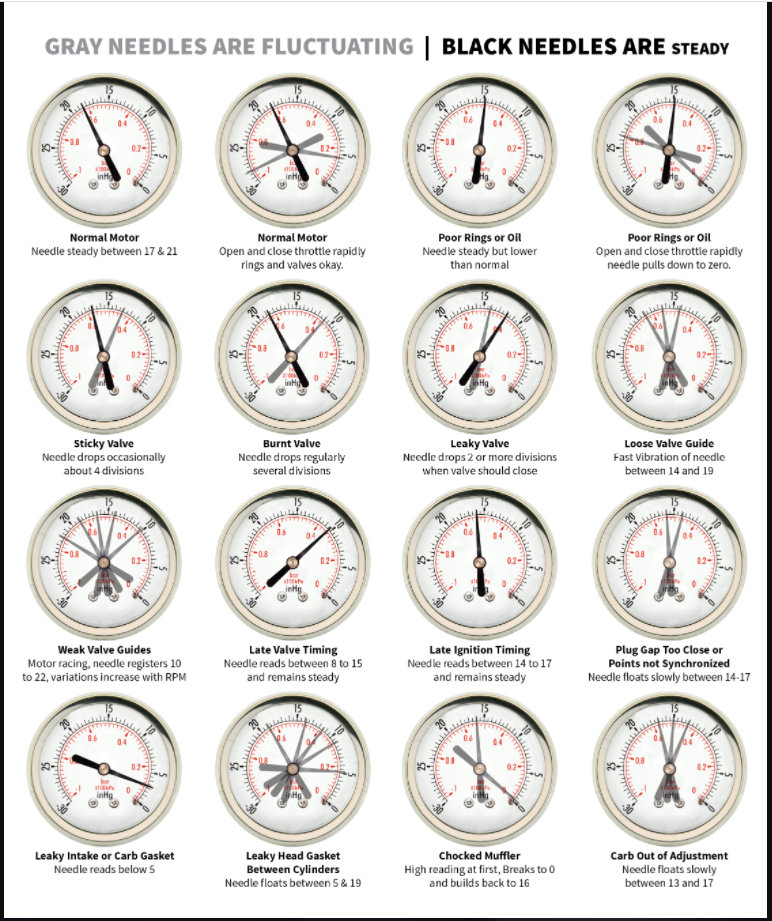

We still need to test for an intake valve issue so we need a vacuum gauge on the engine and let it run.

Also, we need to perform a compression check.

https://www.2carpros.com/articles/how-to-test-engine-compression

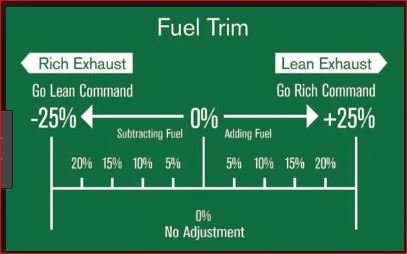

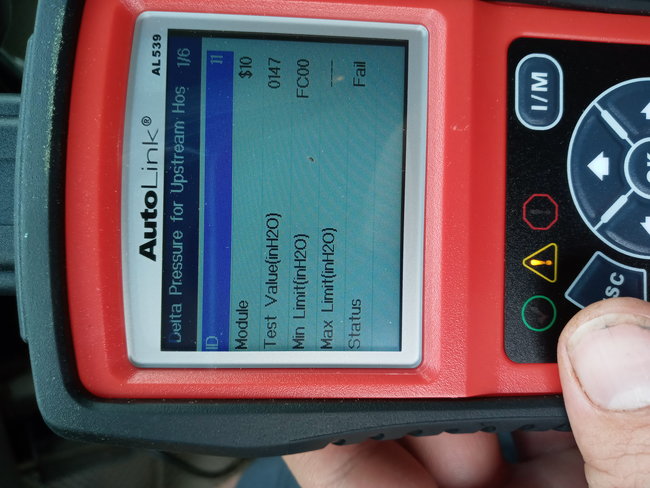

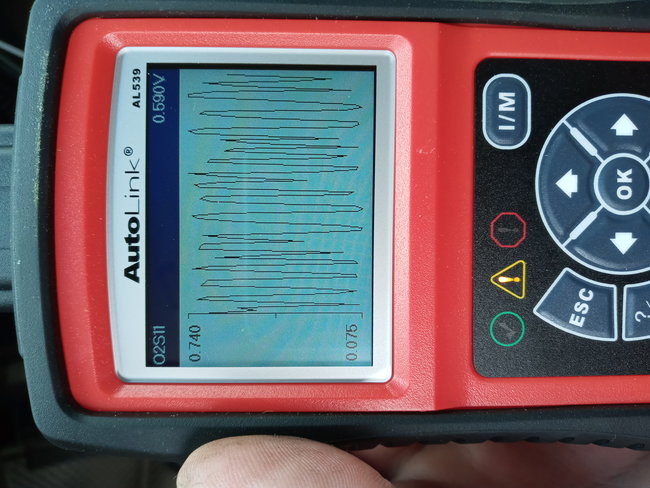

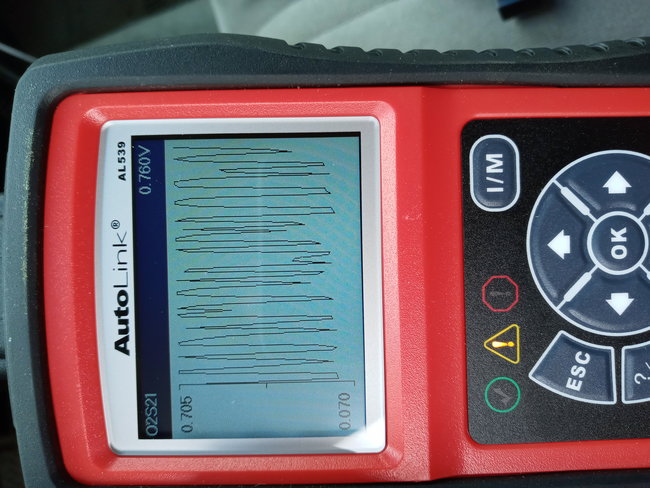

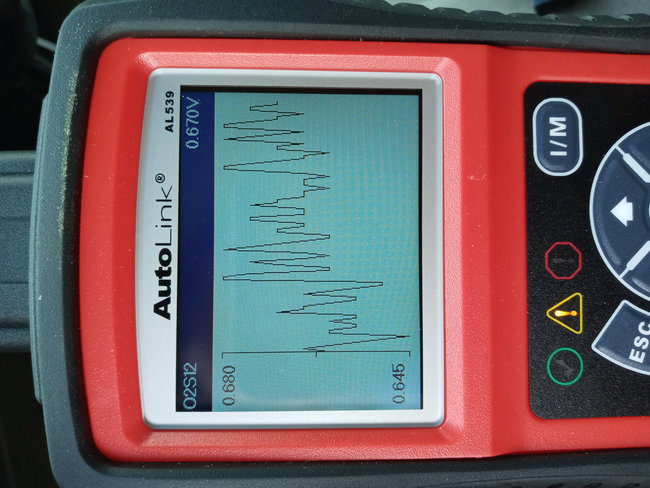

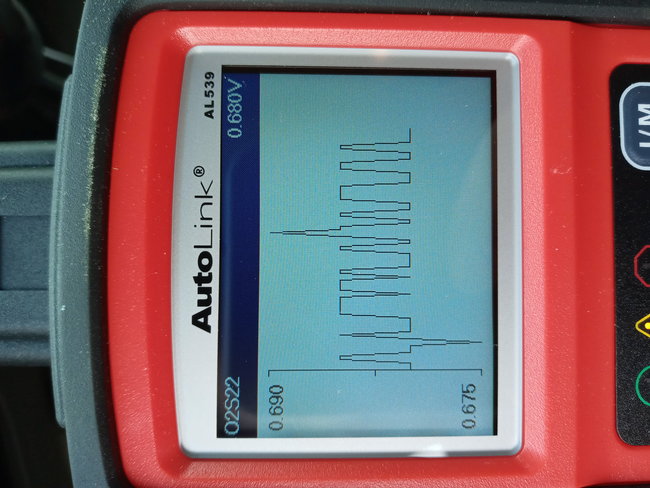

Lastly we need to monitor the o2 sensor data to see if we have a rich or lean condition. So hopefully your scan tool can monitor this.

If we have neither rich or lean, then I suspect the balancer issue will come into this.

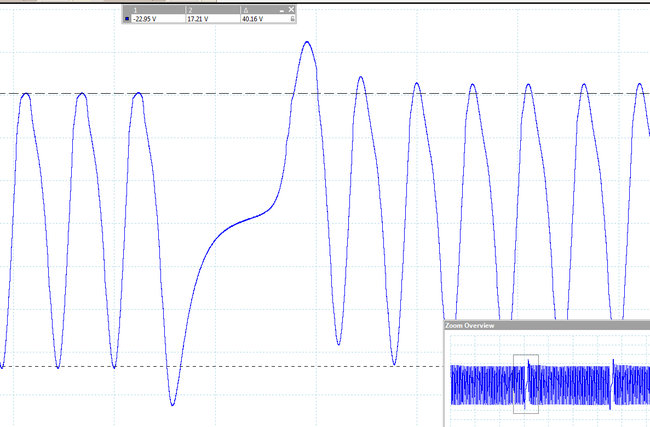

Have you inspected the tone wheel for cracks in the teeth?

Also, below is a chart that will help with vacuum gauge readings but if you can get a video of the gauge, that will as well.

Let us know what questions you have on this. Thanks

Image (Click to make bigger)

Tuesday, May 4th, 2021 AT 4:08 PM