The dual ballast resistor showed up in '72 on Dodges and in '73 on Chryslers and Plymouths. That was part of the world's first electronic ignition system, one of Chrysler's many innovations. Each resistor fed a different terminal on the 5-pin ignition module on the firewall or inner fender. One part of that resistor was a very high-failure item resulting in the engine running only as long as you held the ignition switch in the "crank" position. That's because the failed resistor was bypassed by part of the ignition switch during cranking to develop a stronger spark for easier starting. It was common for people to carry spares in the glove box. They cost around $3.00.

By 1980 the high-failure resistor was left off. Only a single resistor was used, and the same five-pin ignition module was used, but it just had four wires going to it. In addition, some models use an Engine Computer, (another first from Chrysler), hung on the side of the air filter housing. Those also used the single ignition resistor. Those computers were very simple and limited in their capabilities by today's standards, but back then most mechanics didn't understand them or know how to diagnose problems with them. That included me. I did what a lot of other people did which was to replace the distributor with an older version that had the mechanical and vacuum advance built in and wire it to the five-pin ignition module. That's one possible reason you have two different resistors

There also was a single resistor associated with an EGR timer module on the firewall. I never worked on that circuit so I don't know much about it.

Ignition resistors are of the "wire-wound" type and will never be intermittent. They fail by burning open, then have to be replaced That break doesn't fix itself and work at times. What can be intermittent is the connectors plugged into them. This would be very uncommon, but expect to see the resistor's terminals are very rusty and making poor contact with the plugs.

What can be very intermittent is the pick-up coil in the distributor. In fact, your observation of stalling when warm, and working again after cooling down typically for about an hour, fits the pattern perfectly. There's two ways this coil fails. The first is in distributors with the vacuum advance unit on the side, the plate moves back and forth inside the distributor, and that causes flexing of the two wires. Eventually they break, but they usually make intermittent connections for a while before they fail completely. This failure will cause the engine to cut out, then resume running while you're driving and really isn't affected by temperature.

The pick-up assembly is a really long wire coiled up, then the ends are attached to a pair of terminals. Constant changes in temperature cause the wire to expand and contract, eventually leading to one end breaking off its terminal, typically when it heats up. This is the common failure where it works again after the engine cools down for about an hour.

You can verify this with a simple resistance reading, but that has to be done while the coil is in its failed state. You'll need a volt / ohm meter. If you need it, here's a link to an article that shows how to use it:

https://www.2carpros.com/articles/how-to-use-a-voltmeter

They're using an auto-ranging meter which has an expensive feature you don't need. Harbor Freight Tools has a perfectly fine meter for $7.00. I can help you set it up and use it if necessary. You can find these at Walmart and any hardware store too.

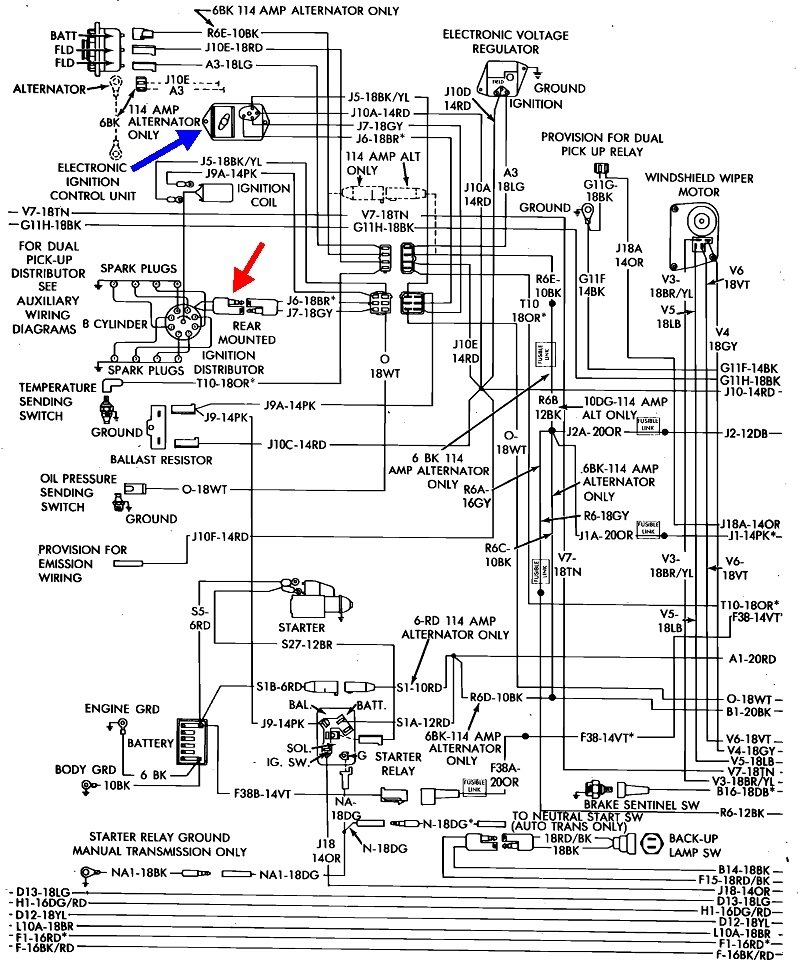

I added a red arrow showing where to measure. You'll see a two-wire plug coming out of the distributor. Most commonly the wires on the distributor side will be black and orange. (I had many of these vehicles, and still have two 1980 Volares). Specifications vary all over the place depending on which service manual you look at, but it can be boiled down to "good" or "bad". Most often the resistance is specified as around 700 to 850 ohms. To know what is correct for your pick-up coil, measure its resistance when the engine is cold. That value is not supposed to change very much with changes in temperature. However, when you measure it again while it's in its failed condition, you'll find an "open circuit', meaning a break in the circuit, the same as when you remove the test probes. That open circuit is proof that coil needs to be replaced.

You may notice some references on this diagram to a "dual pick-up" system. Those have two pairs of wires coming out of the distributor, and a relay mounted on the firewall that switches between them. Those used one pick-up coil while cranking, for easier starting, then it switched to the other pick-up coil for running. Symptoms were a little different when one of them failed. The engine would run either during cranking or while running. I've had a lot of these cars and worked on many more, but I only saw this dual system once. It's too uncommon to worry about covering it unless that is what you have.

If testing proves the pick-up coil needs to be replaced, I'll look for the instructions that should apply to your truck. There were two distributor designs. In one, the coil could just be unbolted and lifted out. The job only took a few minutes. In the other design, the distributor has to be removed and disassembled. While the job can be handled by a competent do-it-yourselfer, this is one time you might want to just buy a rebuilt distributor.

The air gap between the "reluctor", or toothed wheel, and the end of the pick-up assembly is critical. Most applications call for .012". I can tell you from painful experience the engine will not run with a gap of .018". It has to be measured with a brass / non-magnetic feeler gauge. A standard steel gauge can work but it will cause a drag and give the wrong "feel". That gap will already be set if you buy a rebuilt distributor.

Image (Click to make bigger)

Friday, August 13th, 2021 AT 9:39 PM