Hi James and thanks for using 2CarPpros. Com.

Chances are that isn't an issue because the gears are different diameters. If you continue to turn the engine over, most likely it will line up again. Just in case, here are all the directions from Alldata for you to review. This way you can confirm that you did it correctly. All attached pictures correlate with these directions.

__________________________________________

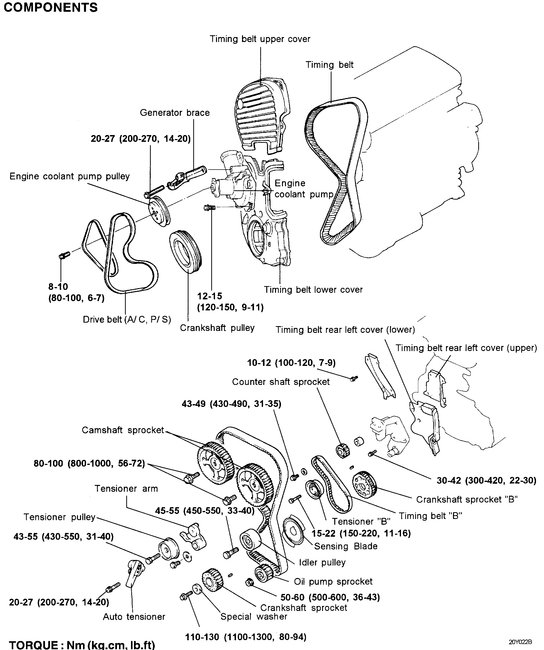

REMOVAL AND REPLACEMENT

REMOVAL

1. Remove the crankshaft pulley, engine coolant pump pulley and drive belt.

2. Remove the timing belt cover.

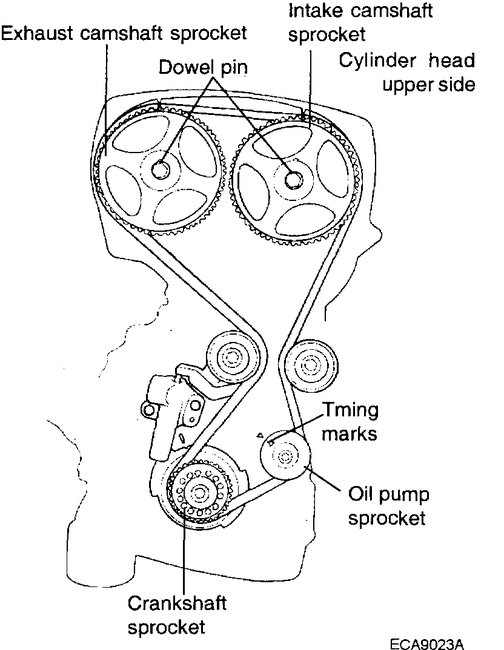

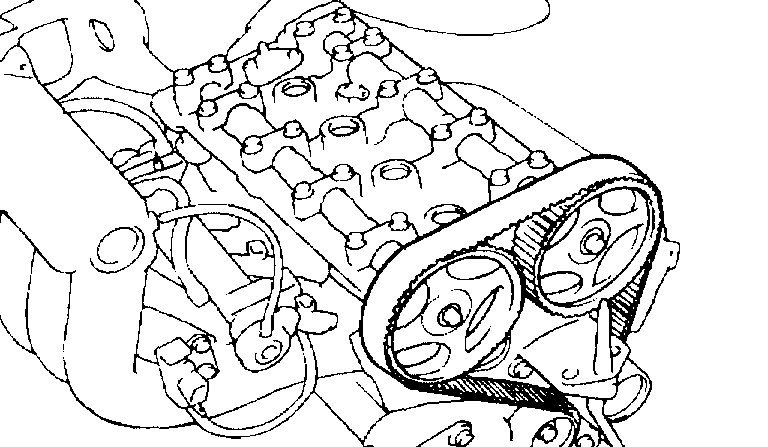

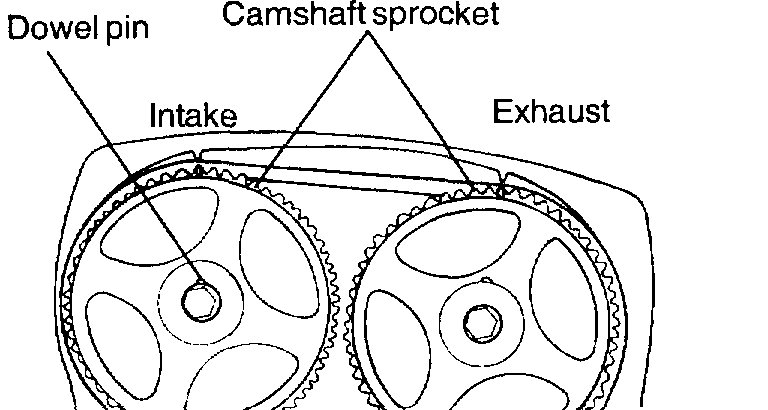

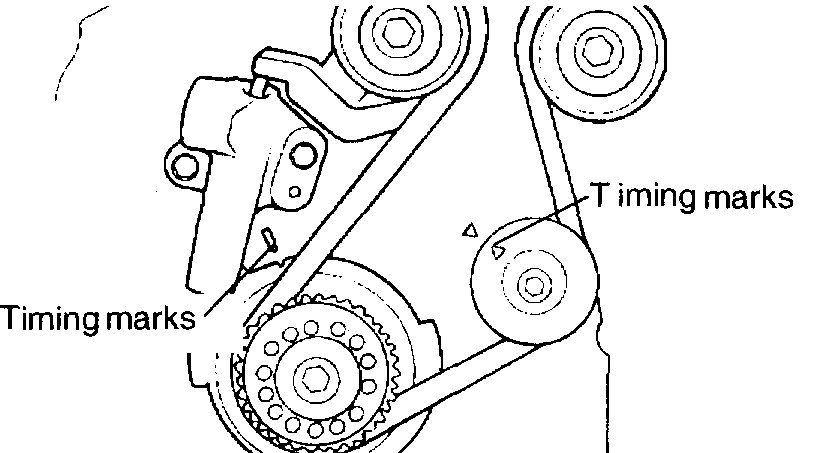

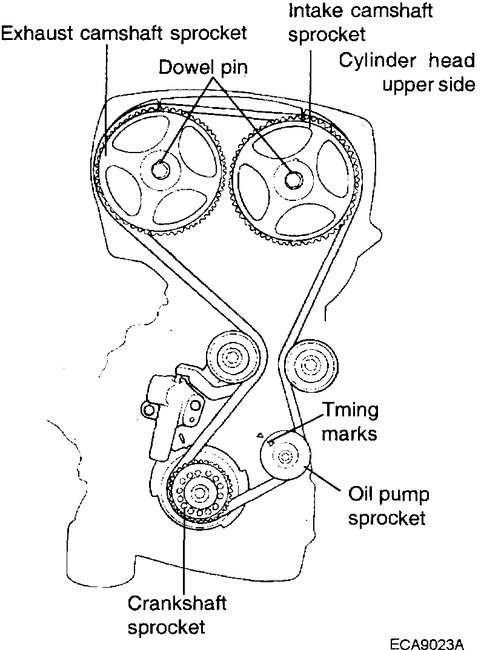

3. Turn the crankshaft clockwise and align the timing marks so as to bring the No.1 cylinder to compression top-dead-center position. At this time the timing marks of the camshaft sprocket and the upper surface of the rocker cover should coincide, and the dowel pin of the camshaft sprocket should be at the upper side. Remove the auto tensioner.

CAUTION: Rotate the crankshaft clockwise.

4. Remove the timing belt.

NOTE: If the timing belt is reused, make an arrow mark indicating the turning direction (or the front of the engine) to make sure that the belt is reinstalled in the same direction as before.

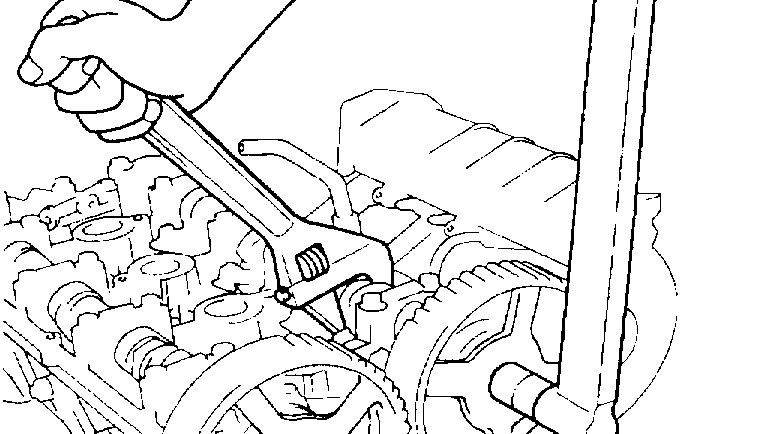

5. Remove the camshaft sprockets.

NOTE: Be careful not to damage the cylinder head with the wrench.

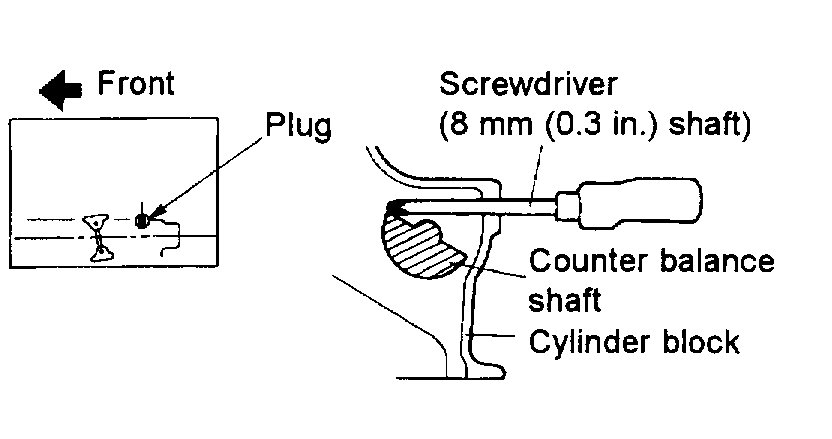

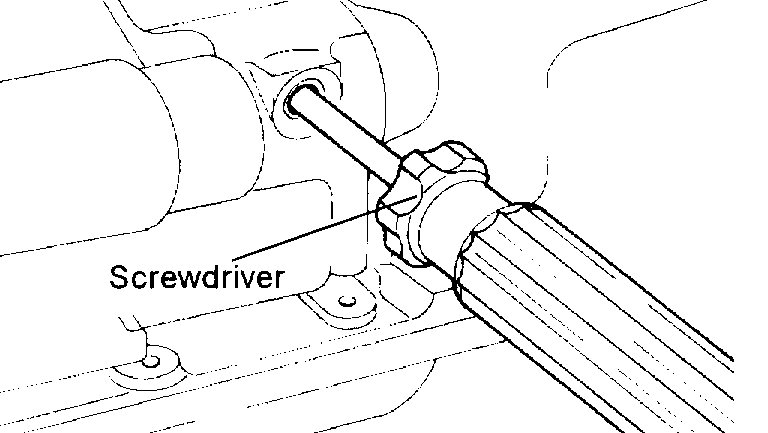

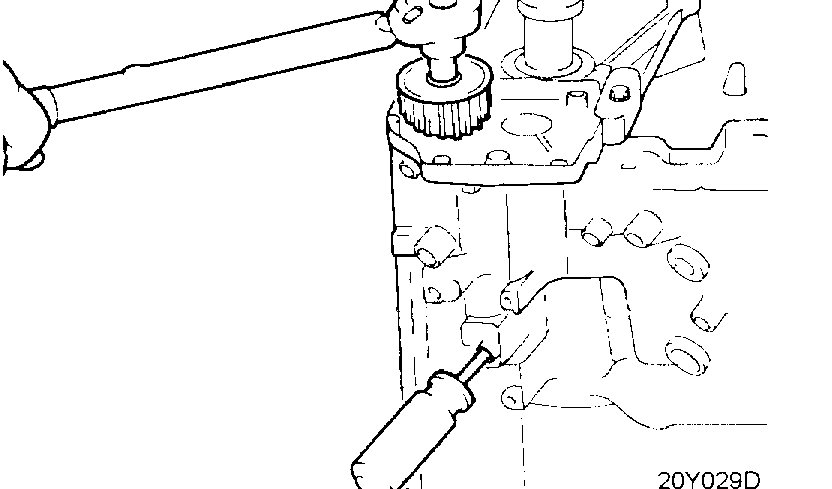

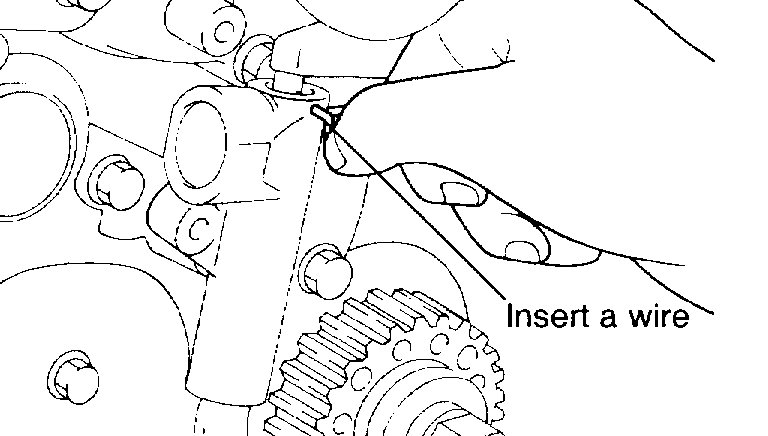

6. When the oil pump sprocket nut is removed, first remove the plug at left side of the cylinder block and insert a screwdriver to check the left counter balance shaft in position. Screwdriver used for this purpose should have a shaft 8 mm (0.3 inch) in diameter which can be inserted more than 60 mm (2.36 inch)

7. Remove the oil pump sprocket retaining nut and remove the oil pump sprocket.

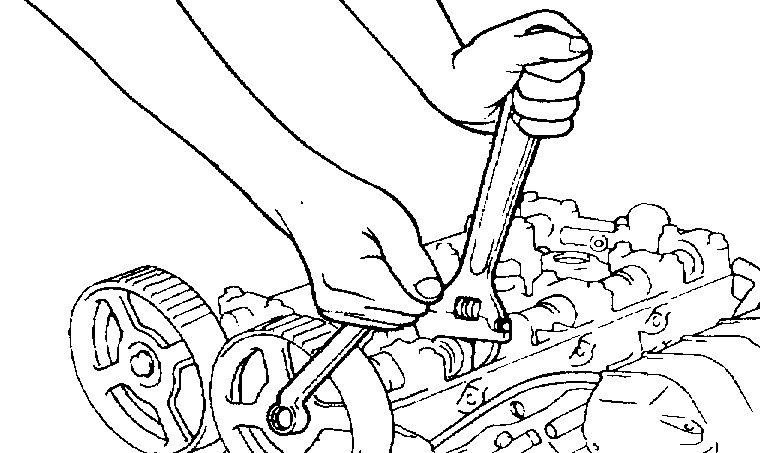

8. Loosen the right counter balance shaft sprocket mounting bolt until it can be loosened by hand.

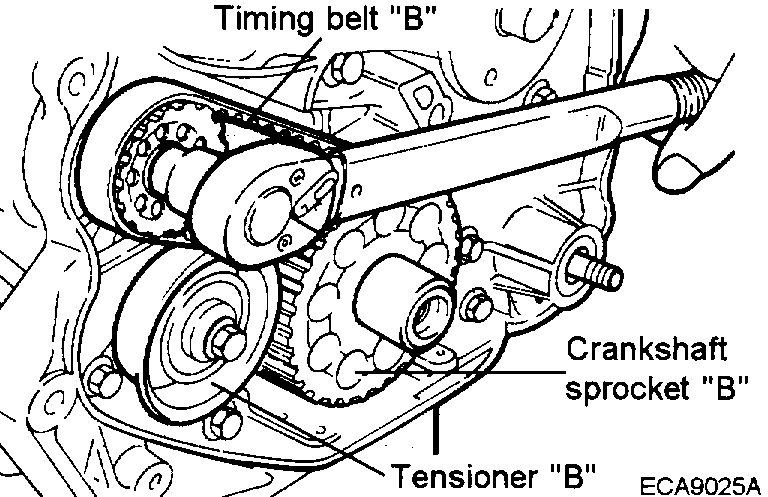

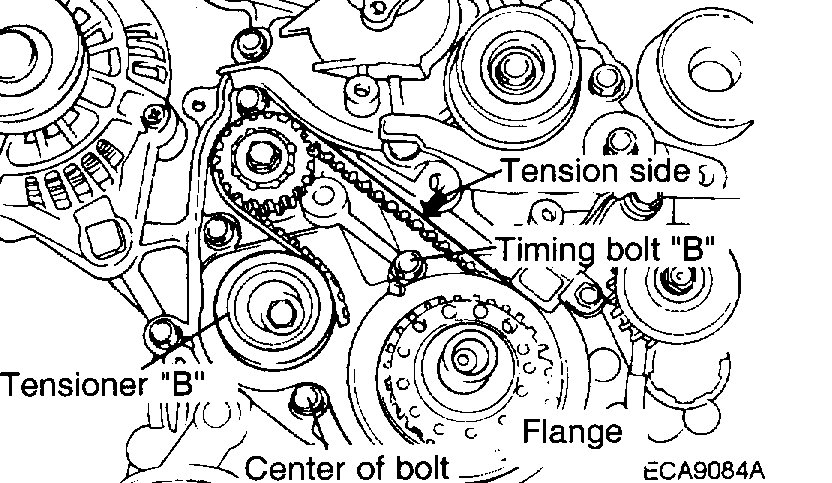

9. Next, remove tensioner "B" and remove timing belt "B".

CAUTION: After timing belt "B" has been removed, do not attempt to loosen bolt while holding sprocket with pliers, etc.

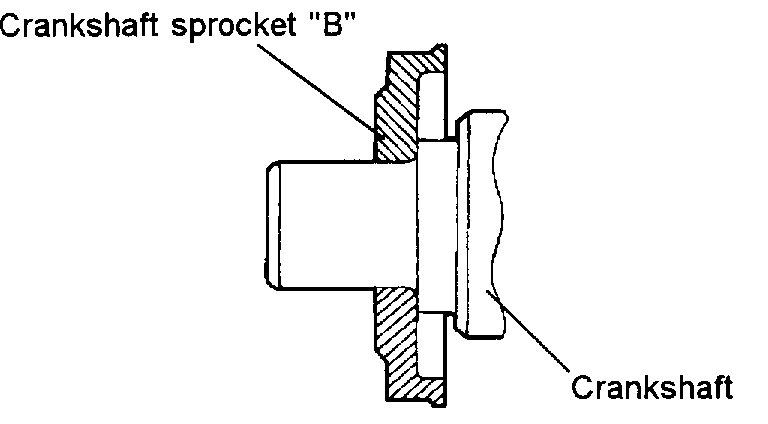

10. Remove the crankshaft sprocket "B" from crankshaft.

INSPECTION

Sprockets, Tensioner Pulley, and Idler Pulley

1. Check the camshaft sprocket, crankshaft sprocket, tensioner pulley, and idler pulley for abnormal wear, cracks, or damage. Replace as necessary.

2. Inspect the tensioner pulley and the idler pulley for easy and smooth pulley rotation and check for play or noise. Replace as necessary.

3. Replace if there is grease leak.

Auto Tensioner

1. Check the auto tensioner for leak and replace as necessary.

2. Check the rod end for wear or damage and replace as necessary.

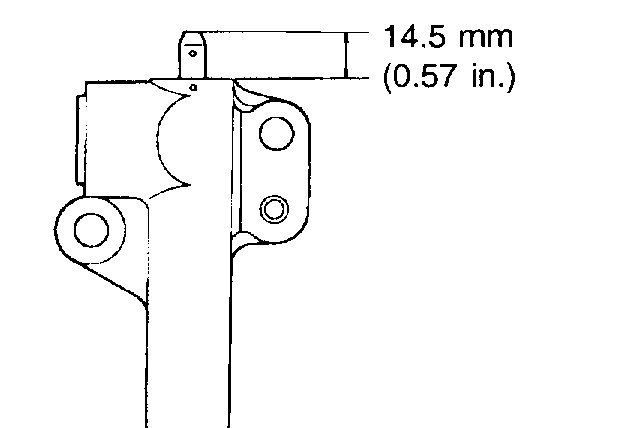

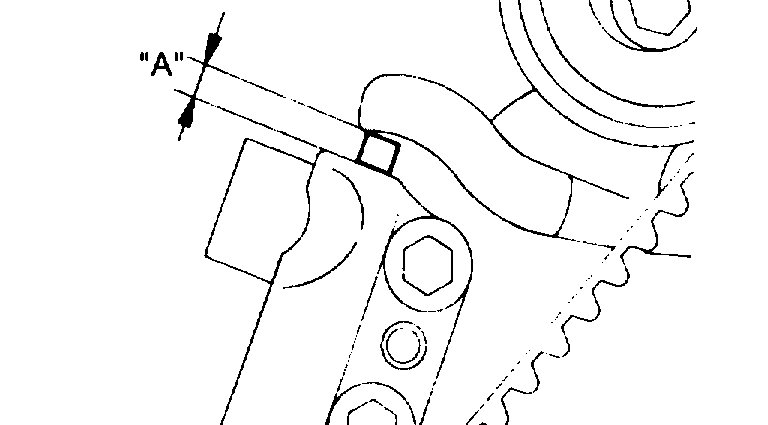

3. Measure the rod protrusion. If it is out of specification, replace the auto tensioner.

Standard value 14.5 mm (0.57 inch)

4. Using a softjaw vise, push the auto tensioner rod. If the rod can be easily retracted, replace the auto tensioner. You should feel a great deal of resistance when pushing the rod in.

CAUTION: Clamp the auto tensioner in the vise so that it can be level. Use soft jaws in the vise to avoid damaging the auto tensioner.

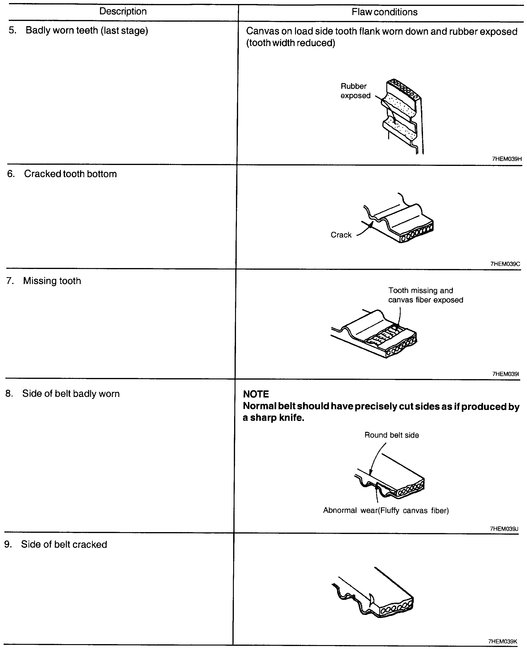

Timing Belt

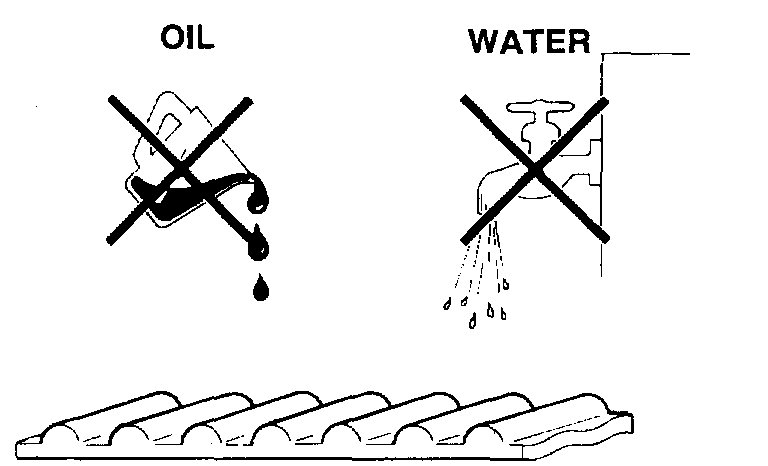

1. Check the belt for oil or dust deposits. Replace if necessary. Small deposits should be wiped away with a dry cloth or paper. Do not clean with solvent.

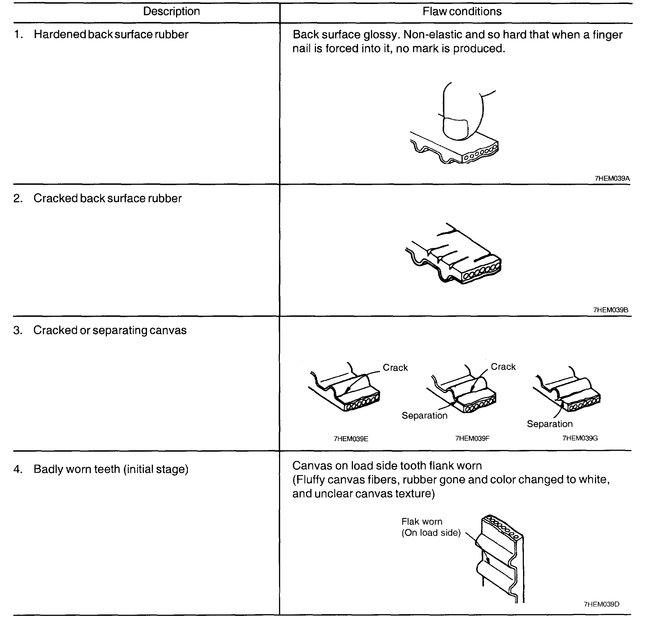

2. When the engine is overhauled or belt tension adjusted, check the belt in detail. If the flaws are evident, replace the belt with a new one.

INSTALLATION

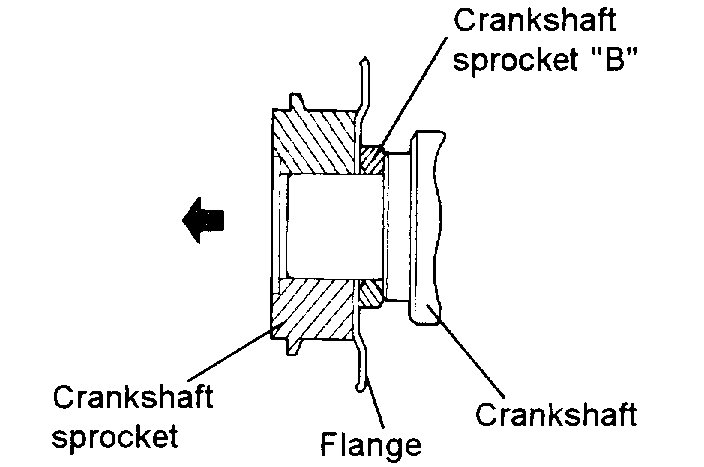

1. Install crankshaft sprocket "B" into crankshaft.

CAUTION: Pay special attention to the direction of the flange. If it is installed in the wrong direction, a broken belt could result from it.

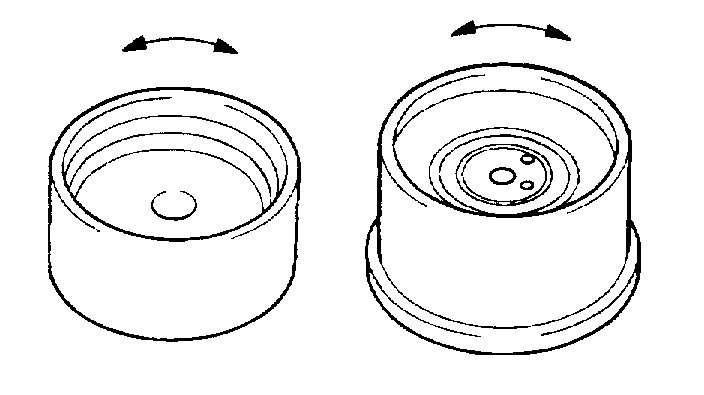

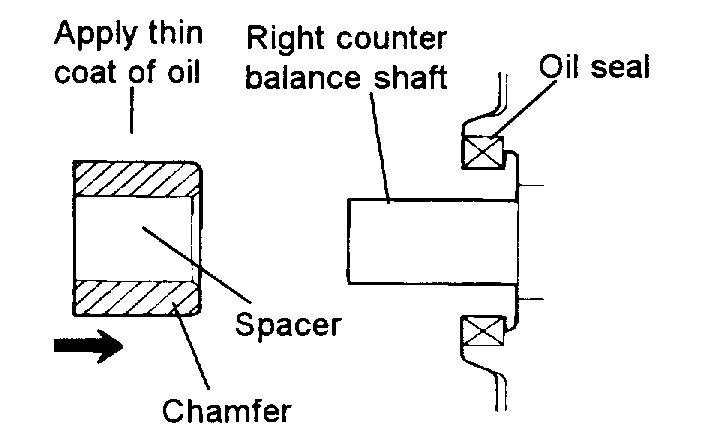

2. Lightly apply engine oil to the outer surface of spacer, and then install the spacer to the right counter balance shaft. Be sure to install as the direction shown in illustration.

3. Install the counter balance shaft sprocket onto the right counter balance shaft, and then tighten flange bolt by hand tightly.

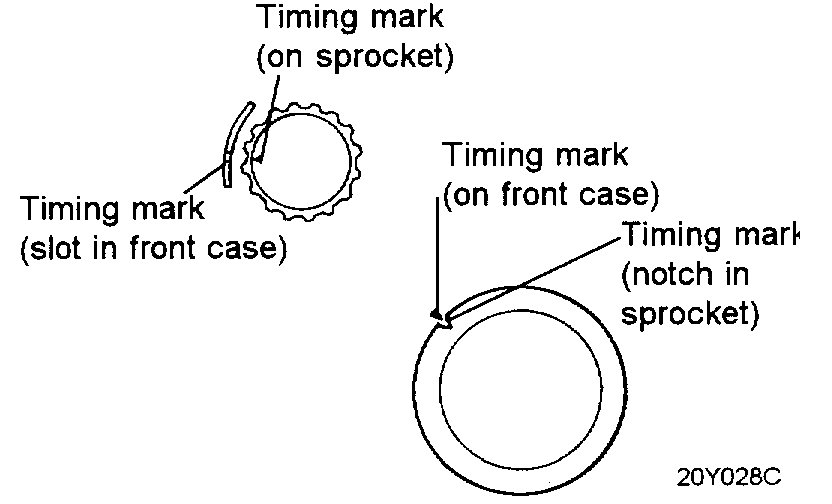

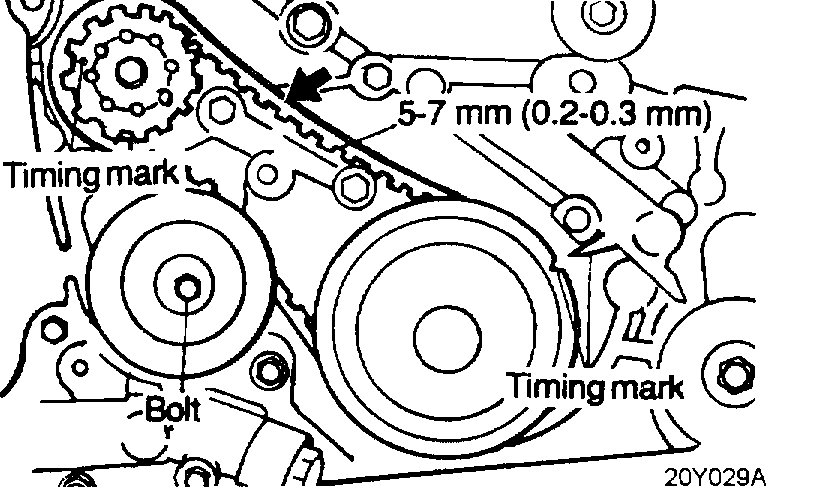

4. Align the timing mark on each sprocket with the corresponding timing mark on the front case.

5. When the timing belt "B" is installed, make certain that tension side has no slack.

Install tensioner "B" in the center of pulley located on the left side of mounting bolt and in the pulley flange directed toward front of engine.

Align the timing mark on the right counter balance shaft sprocket with the timing mark on the front case.

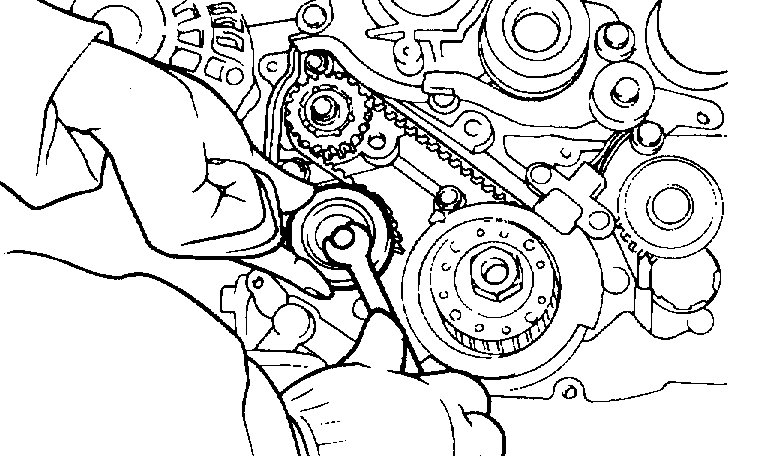

6. Lift tensioner "B" to tighten the timing belt "B" so that its tension side will be pulled tight. In this condition, tighten a bolt to secure tensioner "B". When a bolt is tightened, be careful to prevent from turning together. If the shaft is turned together, the belt will be over tightened.

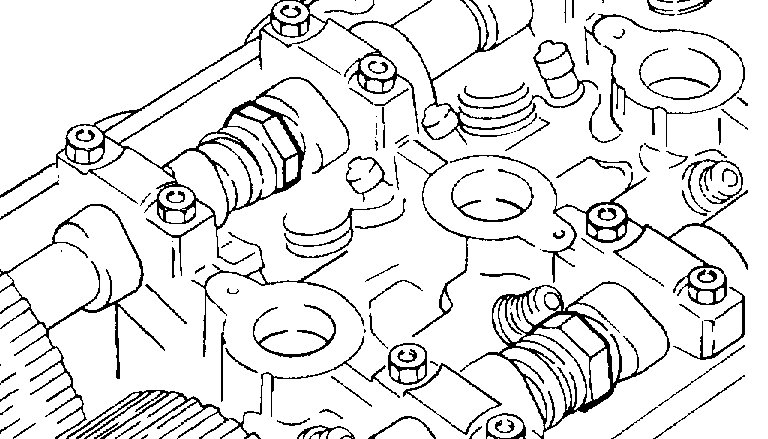

7. Check to ensure that timing marks are in alignment.

8. Check to ensure that when the center of span on the tension side is depressed with index finger in direction of arrow, deflection of belt is within specification.

Belt deflection 5 - 7 mm (0.2 - 0.3 inch)

9. Install the flange and crankshaft sprocket onto crankshaft. Be sure to install as the direction shown in illustration.

CAUTION: Pay attention to direction of flange. If it is installed in wrong direction, a broken belt could result.

10. Install the special washer and sprocket bolt to crankshaft, and then tighten the sprocket bolt.

Tightening torque Crankshaft sprocket bolt 110 - 130 Nm (1100 - 1300 kg. Cm, 80 - 94 ft. Lbs.)

11. Insert a screwdriver through the plug hole in left side of cylinder block to keep shaft in position.

12. Install the oil pump sprocket, and tighten the nut to the specified torque.

13. Install the camshaft sprocket and tighten the bolt to the specified torque.

Tightening torque Camshaft sprocket bolt 80 - 100 Nm (800 - 1000 kg. Cm, 56 - 72 ft. Lbs.)

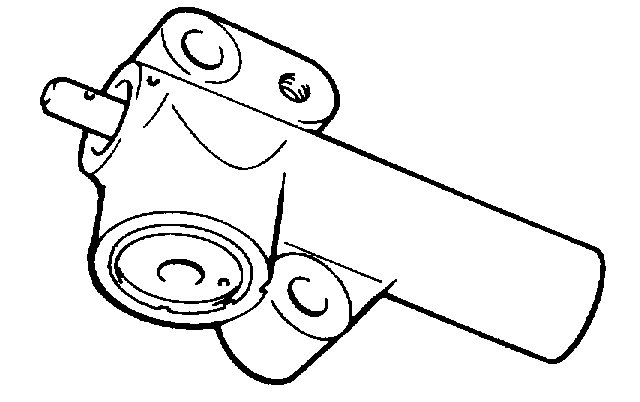

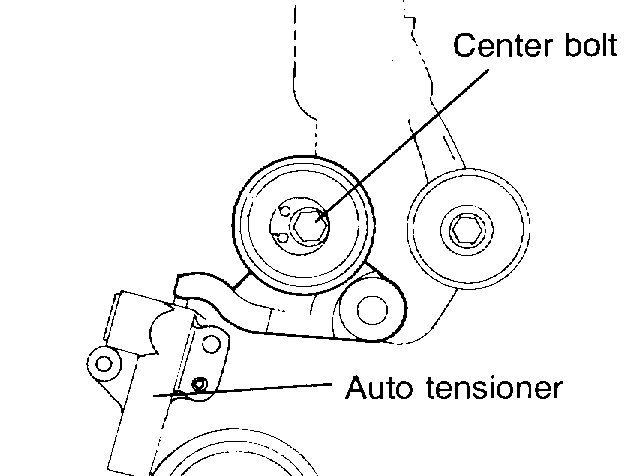

14. Install the auto tensioner.

CAUTION: Leave the set pin installed in the auto tensioner

NOTE:

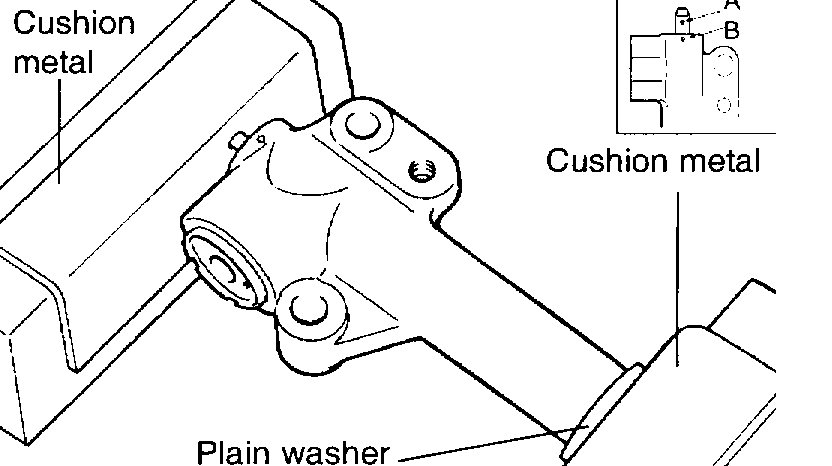

If the auto tensioner rod is in its fully extended position, reset it as follows.

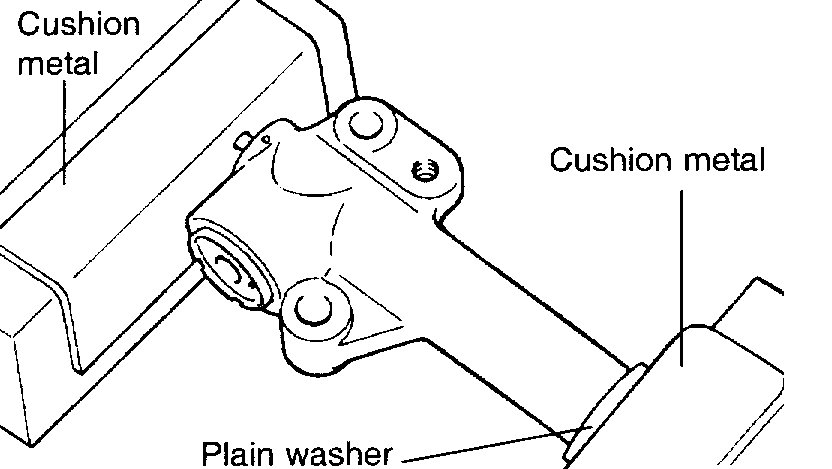

1 Clamp it in the vise with soft jaws in a level position. Apply a plain washer if there is a plug at the bottom of the auto tensioner.

2 Push in the rod slowly with the vise until the set hole A in the rod is aligned with the set hole B in the cylinder.

15. Install the tensioner pulley onto the tensioner arm.

CAUTION: Leave the wire installed in the auto tensioner.

16. After installing the crankshaft sensor, set the timing mark of sprocket correctly.

NOTE:

1 Before installing the timing belt, If the timing mark of cam sprocket doesn't coincide with that of rocker cover, do not rotate the cam sprocket more than 2 teeth of sprocket in any direction.

Rotating sprocket more than 2 teeth makes valve and piston touched each other.

2 In case of rotating the cam sprocket unavoidably more than 2 teeth, rotate the cam sprocket after rotating crank sprocket counter clock wise on basis of timing mark.

17. Align the crankshaft sprocket timing marks.

18. Align the oil pump sprocket timing marks.

19. Install the timing belt around the tensioner pulley and crankshaft sprocket. Then secure the timing belt onto the tensioner pulley with your left hand.

20. Pulling the belt with your right hand, install it around the oil pump sprocket.

21. Install the belt around the idler pulley.

22. Install it around the intake camshaft sprocket.

23. Turn the exhaust camshaft sprocket one tooth clockwise to align its timing mark with the cylinder head top surface. Then, pulling the belt with both hands, install it around the exhaust camshaft sprocket.

24. Gently raise the tensioner pulley as shown by the arrow so that the belt can't sag, and temporarily tighten the center bolt.

25. Check again whether the timing mark of each sprocket is correct or not.

26. Remove the fixed wire that is attached to auto tensioner.

27. Rotate the crankshaft two complete turns clockwise and leave it for about 15 minutes. Then, measure the auto tensioner protrusion "A" (distance between the tensioner arm and auto tensioner body) to ensure that it is up to specification.

Standard value 6 - 9 mm (0.24 - 0.35 inch)

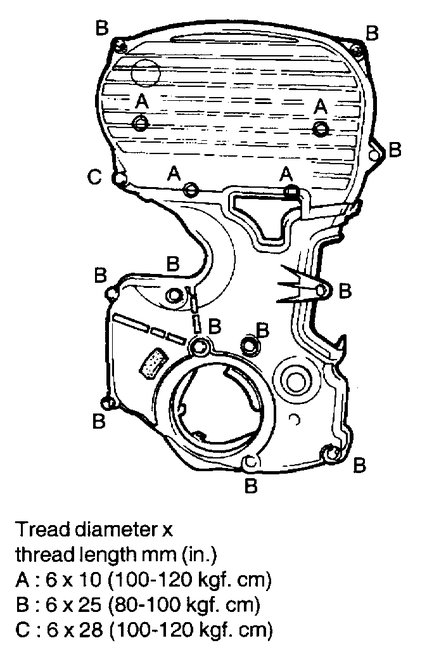

28. Install the timing belt lower cover and the timing belt upper cover.

__________________________________

As I mentioned, as long as you have everything together and aligned as the directions indicate, it should be fine.

I hope this helps. Let me know if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Monday, September 24th, 2018 AT 6:45 PM