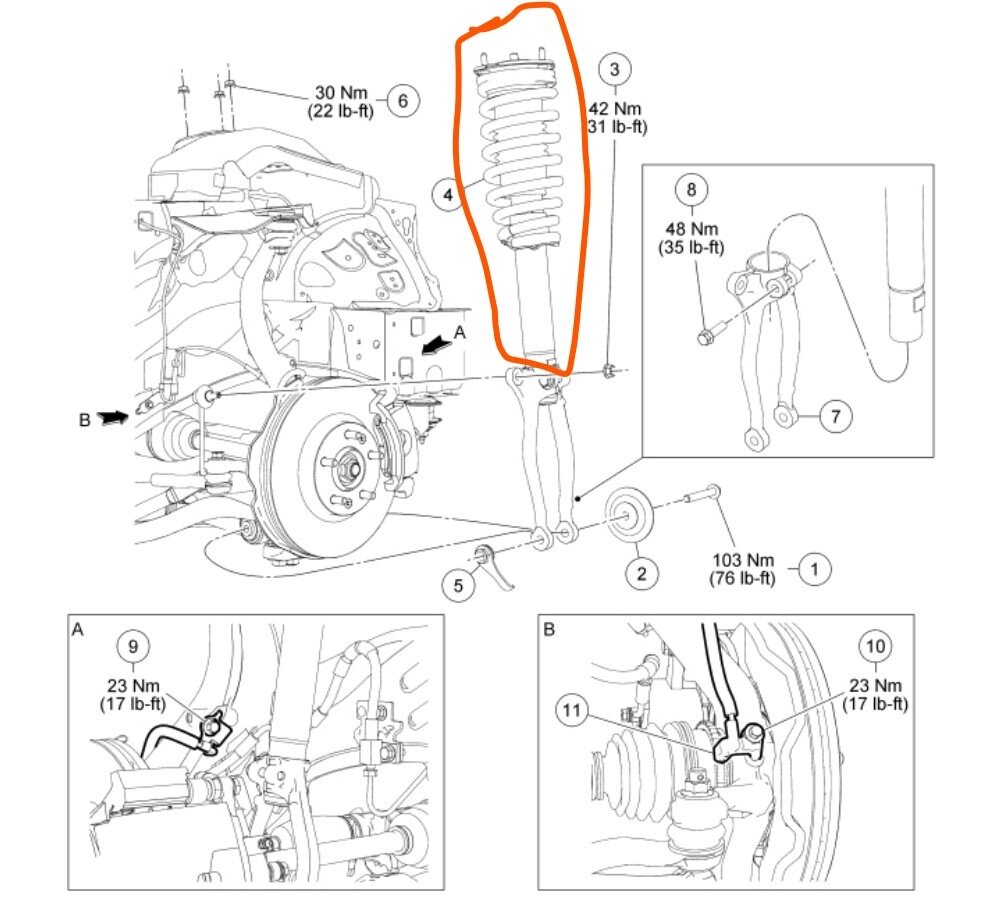

It's always best to replace them in pairs because of the wear and internal valving. If you use the same OE part, it doesn't matter as much but many will use an aftermarket part that might not be exactly the same. That can cause issues. On that chassis it's actually really easy to do if you have a good jack and stands. That is because the strut slips into a yoke at the bottom so in reality you have a lot less work, especially if you were to buy a pair of loaded struts that come fully assembled. You pretty much jack up the front of the car using the body or under the subframe jack points so the suspension can droop. Then take the wheel off. Next apply a bit of penetrant to the yoke where the strut slips in and loosen and remove the pinch bolt. Disconnect the wheel speed sensor so you don't stretch the cable and loosen the brake caliper and slip it off for the same reason. Steer fully to the side you are working on as well so the steering can drop farther. Now go to the top of the strut where the 3 nuts secure it to the chassis under the hood. Next jack the car up until the suspension is hanging mostly free and slip the bottom of the strut out of the yoke, pull it out and let the top come out of the upper mounts. Now install the replacement by putting the top into place then the bottom. Let the car down so the strut can fully seat and tighten the pinch bolt and the upper nuts to spec. Now put the caliper back in place and the wheel speed sensor. Install the tire and repeat on the other side.

You can get the OE style loaded strut for that car for around $120.00 aside from places like Rock Auto. Motorcraft ASTL 22 (left) and 23 (right) Book time is around 3 hours to change both sides but using the shorter method I've done both in about half that time.

Images (Click to make bigger)

Thursday, January 9th, 2025 AT 5:39 AM