Monday, July 31st, 2023 AT 1:44 AM

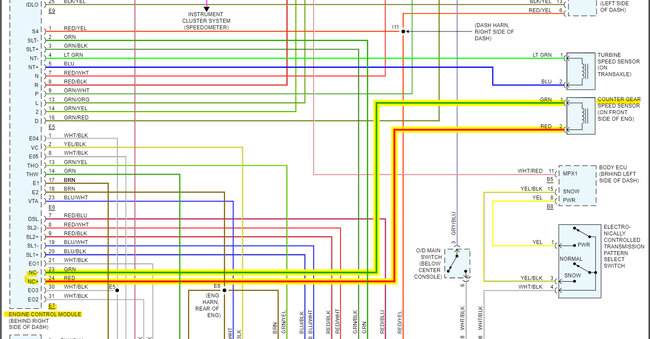

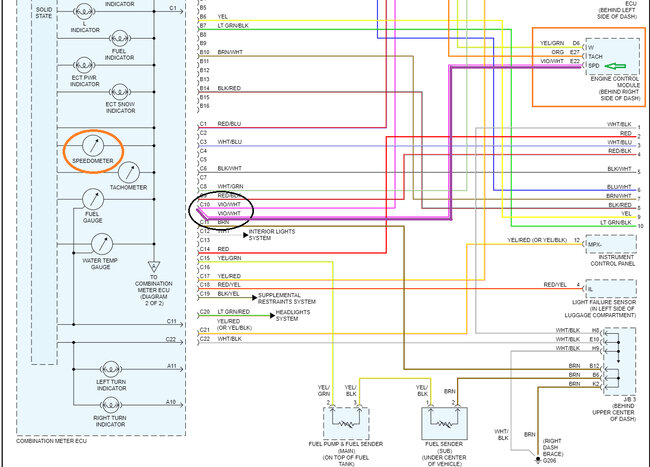

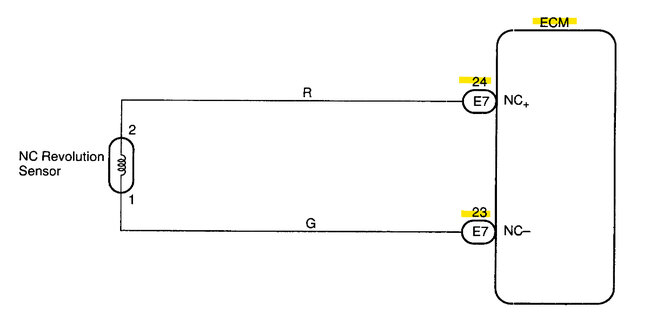

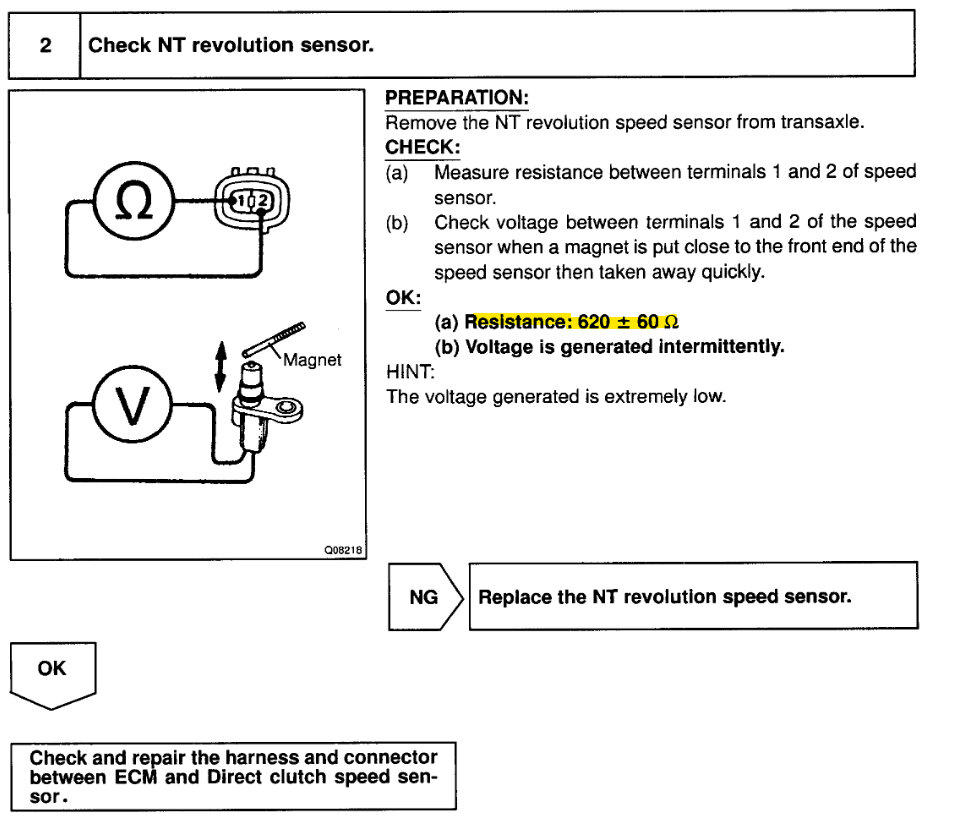

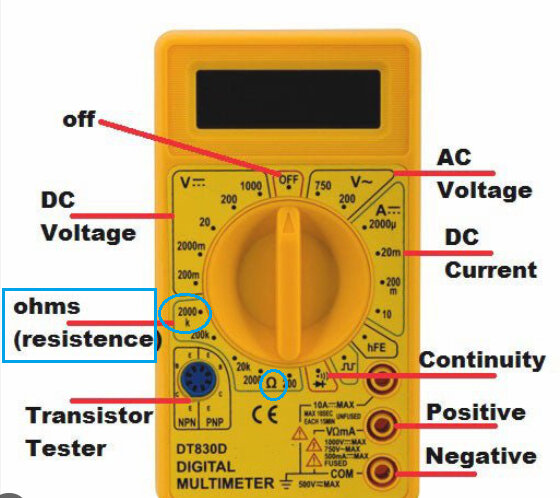

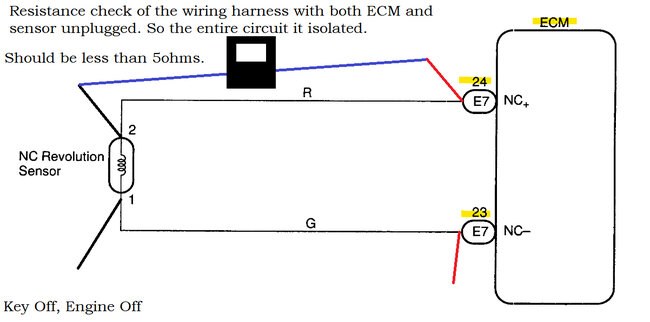

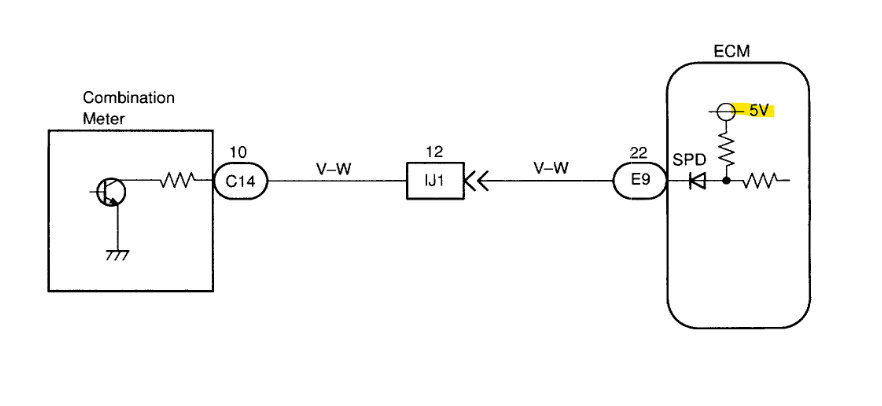

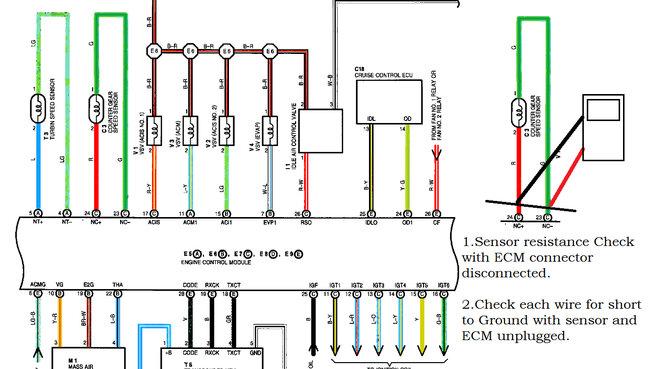

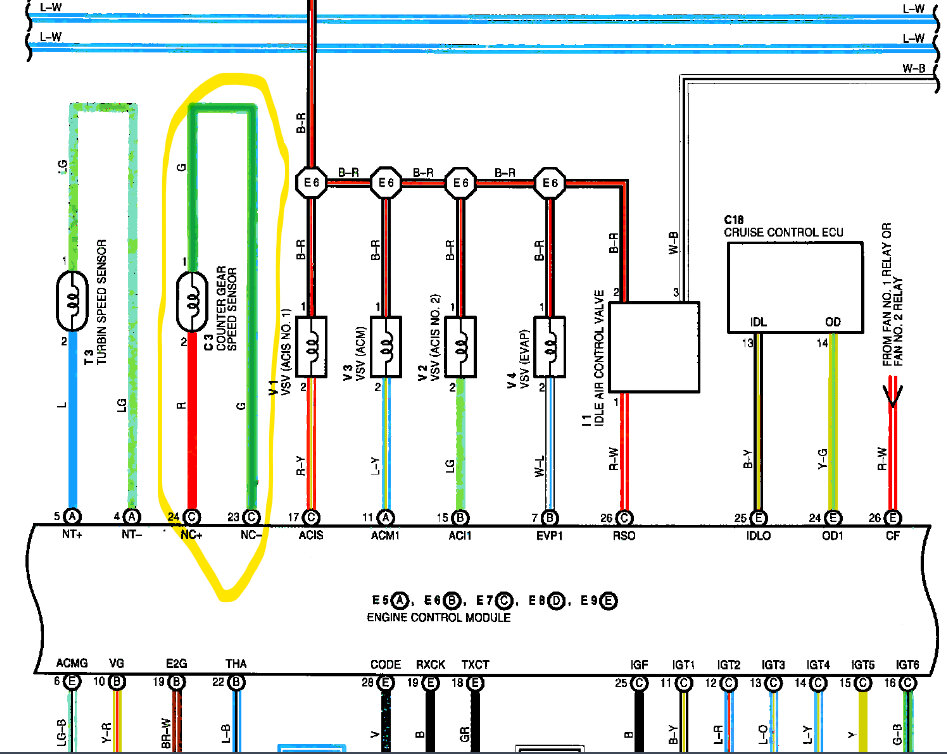

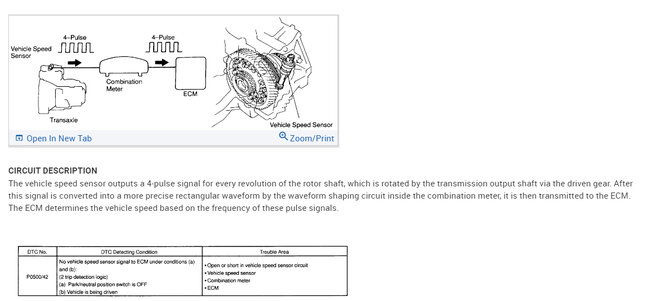

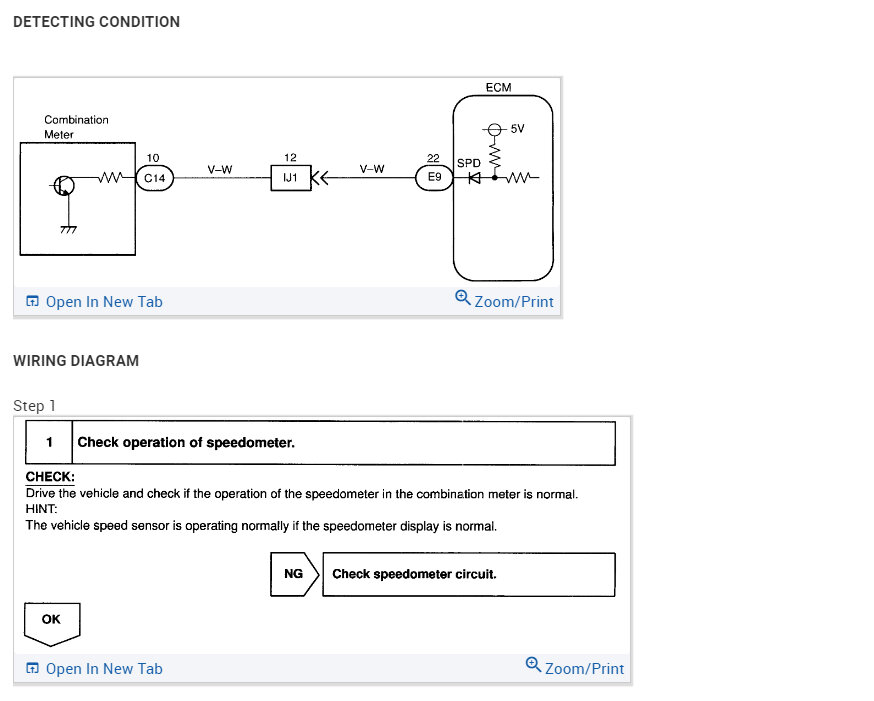

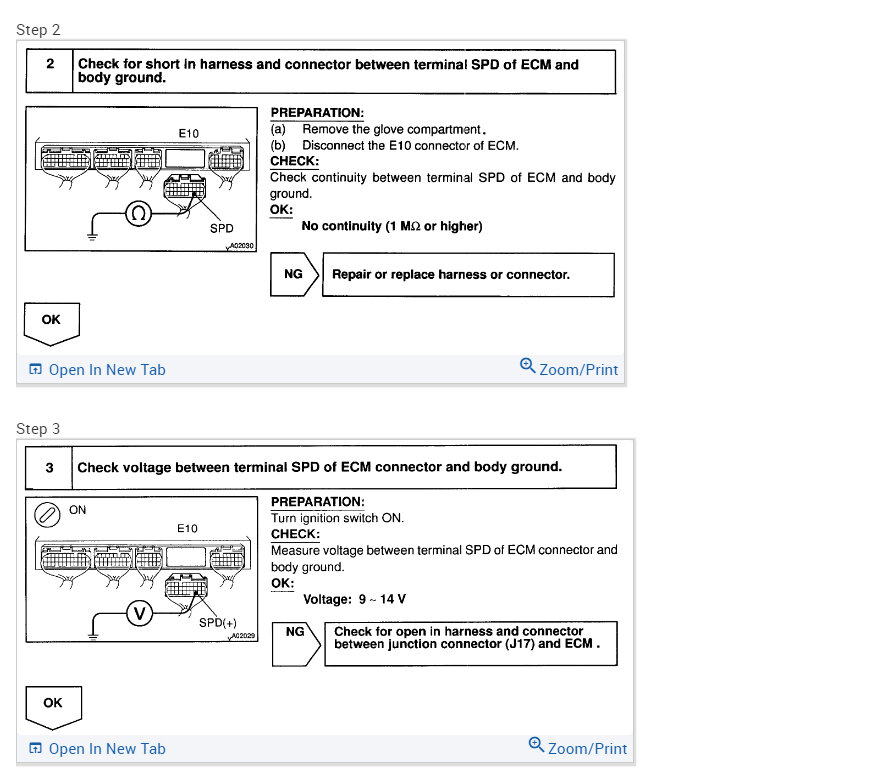

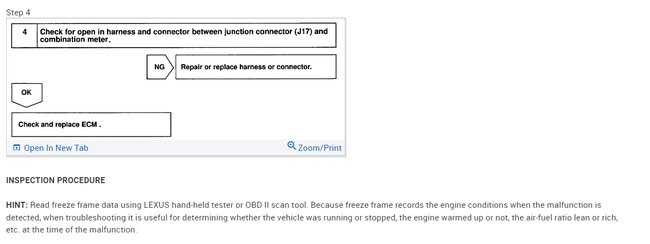

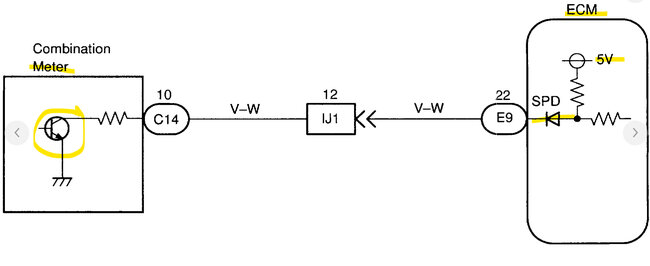

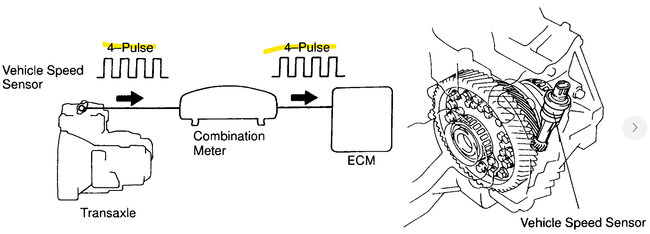

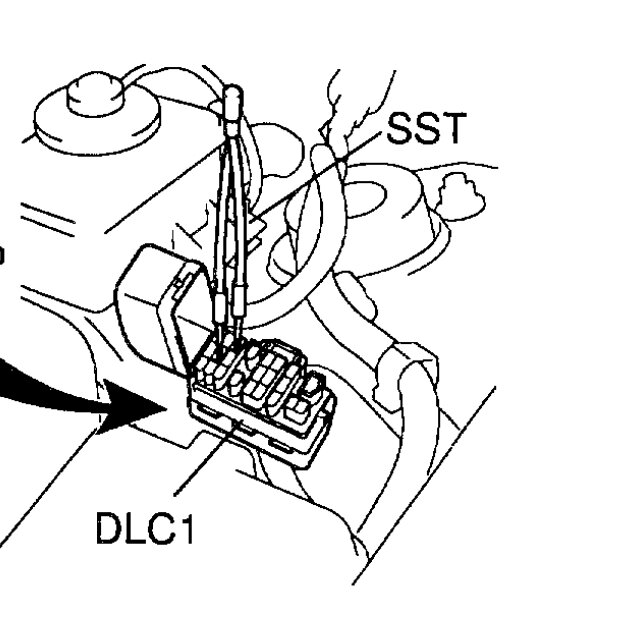

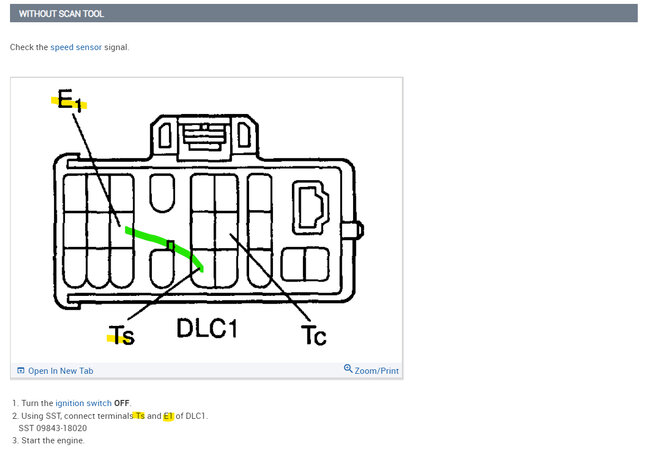

The speedometer stopped working after coil replacement. I have changed the ABS Module, it worked and stopped again. I used another speed clock and check, and it didn't work. I changed the ABS Actuator without connecting the brake pipes and it didn't work. I got another ECM and program it but it still didn't work. So, I began circuit by checking power supply to ABS module from ECU-B Fuse and there's power supply. I checked the Speedline wire violet/white; from ECM E9(22) to speed clock C3(10) and there was continuity, I measured the voltage with ignition on and it read 4.67volts. I also checked the Speedline wire (yellow wire) from ABS ECU B (16) to speed clock A (17) with engine on and gear shifter in D-position with one wheel spinning and it read 10volts. Finally, I measured voltage on the ABS sensor FR and FL, with the sensor disconnected it reads 0.5volts and when you plug in the sensor connector it drops from 0.5 to 45-50mv. At this point, I want to know how many volts the ABS ECU uses to control the sensor.