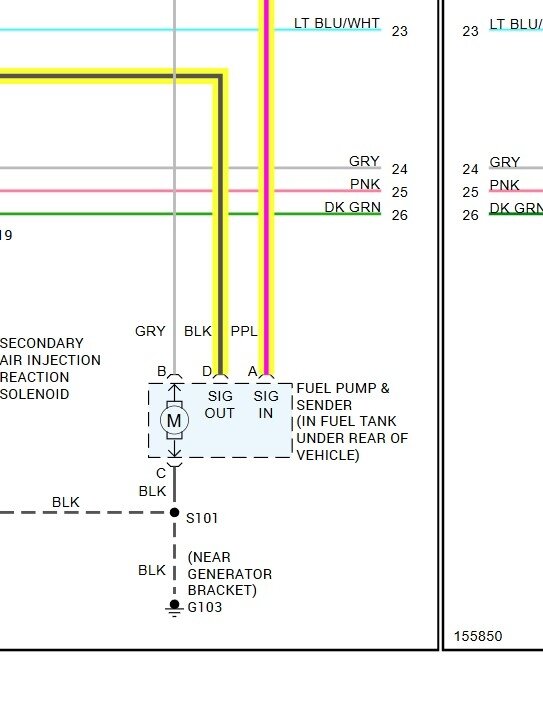

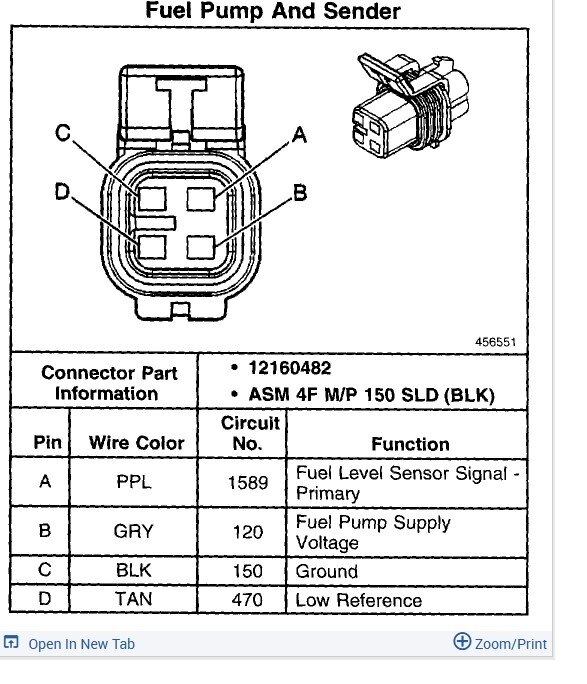

GM did change the pump connector on the newer pumps in an attempt to prevent the failures the earlier design had. However, the aftermarket pumps usually come with the new pigtail and the directions of which wire connects to what. The problem is that many of the aftermarket pigtails come with similar colored wires. The idea is that you look at the OE wiring and then match the functions to the replacement connector. As they replaced the module itself along with the wiring it could be the wiring, or the pump module might have a defective sending unit. Hard to know without testing them outside the tank. Connecting the wiring wrong might have done damage but it would depend on which wires they were. If the two for the gauge were reversed it would have made the gauge work in reverse, so as you added fuel the level would have gone down. If they reversed the grounds, it would likely have damaged the cluster as it passed a lot more current to power the pump than the gauge would have used. You could use a scan tool that can read live data and see if it acts erratic, if it does as well then it isn't the cluster but the sending unit. What you might want to do is get a second shop to look at it, tell them that you had a shop replace it and how they had to redo the wiring and now the gauge is bouncing. See if they will bill the first shop.

Images (Click to make bigger)

Thursday, January 23rd, 2025 AT 4:33 PM