Have you retrieved any trouble codes from the pcm or tcm?

Here also is a test procedure for the shift solenoids.

TEST A: SHIFT SOLENOIDS

Electronic Diagnostics

Ensure transaxle harness connector is in acceptable condition. Repair as necessary. Ensure transaxle harness connector is fully seated. Connect NGS tester or equivalent to DLC. Perform KOEO test until Continuous Memory trouble code(s) have been displayed. See QUICK TEST . Enter output test mode. See ADDITIONAL SYSTEM FUNCTIONS . Select ALL ON mode. Push START to turn outputs ON. Push STOP to turn outputs OFF. If vehicle enters output state, go to next step. If vehicle will not enter output state, see SCAN TOOL UNABLE TO COMMUNICATE .

Check Electrical Signal Operation

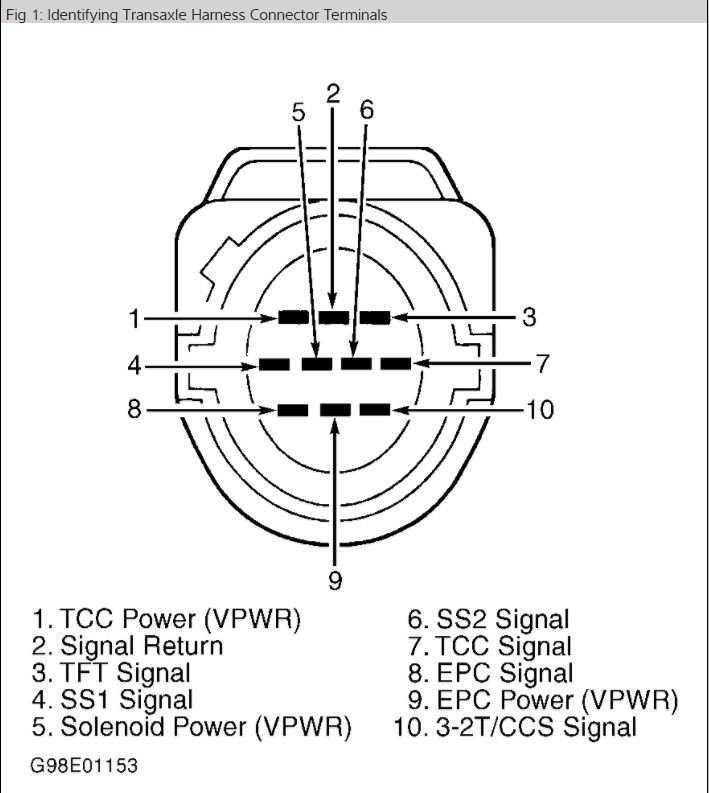

Turn ignition off. Disconnect transaxle harness connector. Inspect condition of connector and repair as needed. Turn ignition on. Using DVOM, connect positive lead to transaxle harness connector terminal No. 5. See Fig 1. Connect negative lead to suspect solenoid circuit. While monitoring DVOM, press START and STOP to cycle solenoid output on and off. If voltage changes at least.5 volt, go to step . If voltage is unaffected, go to next step.

Fig 1: Identifying Transaxle Harness Connector Terminals

G98E01153

Courtesy of FORD MOTOR CO.

Check Continuity Of Solenoid Signal & VPWR Harness Circuits

Ensure ignition is off. Disconnect PCM 104-pin connector, and inspect it for damaged pins, corrosion and loose wires. Repair as necessary. Install breakout box, leaving PCM disconnected. Measure and record resistance between breakout box test pin No. 1 and transaxle harness connector terminal No. 6. See Fig 1. Measure and record resistance between test pin No. 27 and transaxle harness connector terminal No. 4. Measure and record resistance between test pins No. 71 and 97 and transaxle harness connector terminal No. 5. If any resistance is greater than 5 ohms, repair open circuit. Connect all components. Disconnect breakout box and repeat QUICK TEST . If each resistance is 5 ohms or less, go to next step.

Check Solenoid Harness For Shorts To Power & Ground

Measure and record resistance between breakout box test pins No. 1 or 27 and test pins No. 71 and 97. Measure and record resistance between chassis ground and test pin No. 1 or 27, and between chassis ground and test pins No. 24, 51, 76, 77, 91 and 103. If any resistance is less than 10 k/ohms, repair short circuit. Connect all components. Disconnect breakout box and repeat QUICK TEST . If each resistance is 10 k/ohms or more, go to next step.

Solenoid Functional Test

Connect transaxle tester. Perform solenoid voltage test. See tester instructions. If solenoid activates (Green LED on), go to next step. If solenoid does not activate LED, go to step .

Transaxle Drive Test

Connect PCM 104-pin connector. Perform tester drive test. See tester instructions. If vehicle upshifts when operated with tester, replace PCM. Connect all components. Disconnect breakout box and repeat QUICK TEST . If vehicle does not upshift when operated by tester, go to next step.

Check Resistance Of Solenoid

Set tester Bench/Drive switch to BENCH position. Set Solenoid Selector switch to OHMS CHECK. Connect ohmmeter negative lead to SS1 jack and positive lead to VPWR jack on tester. Measure and record resistance. Connect ohmmeter negative lead to SS2 jack and positive lead to VPWR jack on tester. Measure and record resistance. Resistance for both solenoids should be 12-22 ohms. If resistance is within specification, go to next step. If resistance is not within specification, replace solenoid body assembly. Erase all trouble codes. See CLEARING CODES . Repeat QUICK TEST .

Check Solenoid For Short To Ground

Check continuity between BAT(-) terminal and between SS1 and SS2 jacks. If continuity exists, replace solenoid body assembly. Erase all trouble codes. See . Repeat QUICK TEST . If continuity does not exist, see TROUBLE SHOOTING in FORD CD4E (MAZDA LA4A-EL) OVERHAUL article for non-electronic symptom diagnostics.

Image (Click to make bigger)

Sunday, March 25th, 2018 AT 7:50 AM