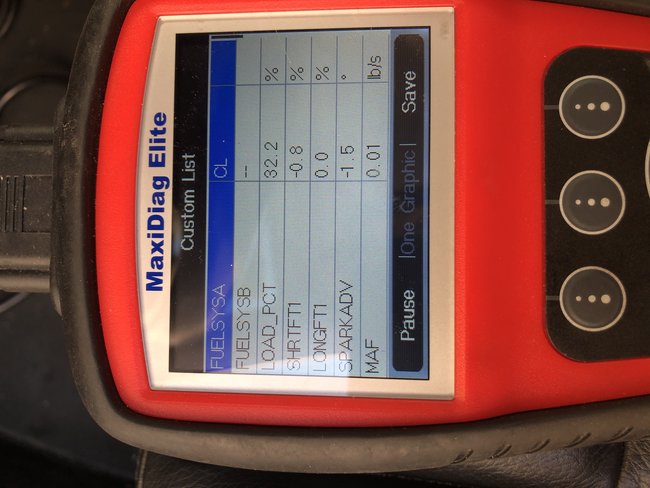

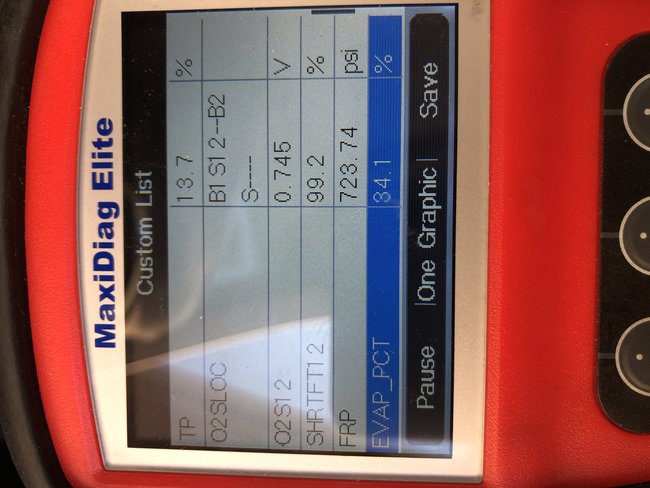

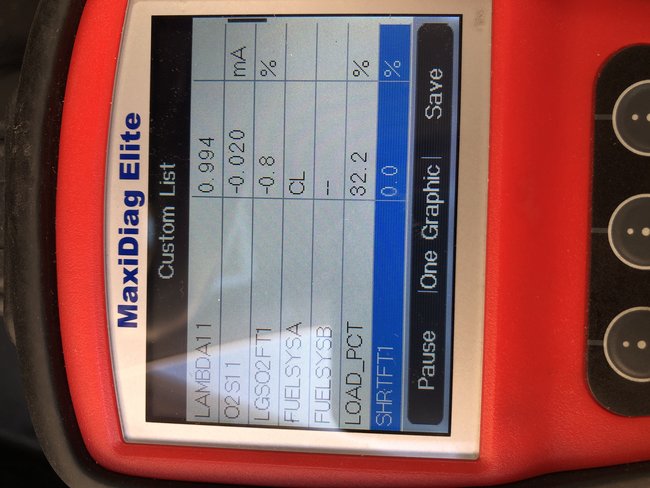

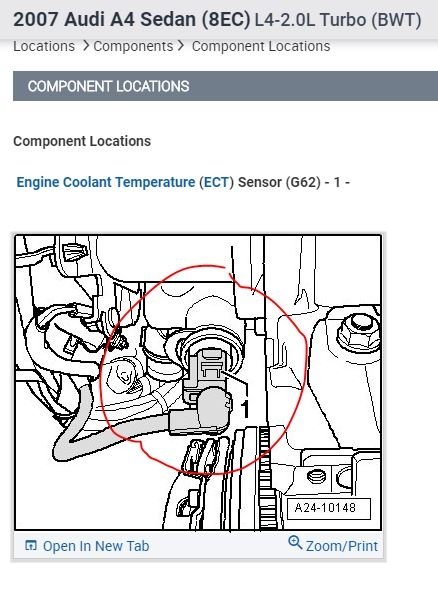

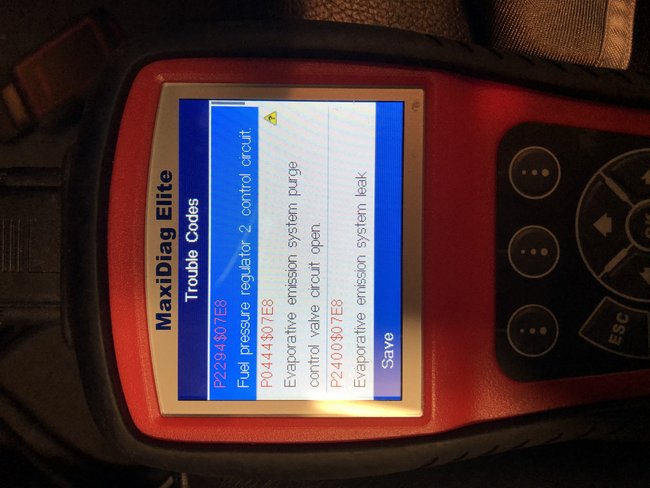

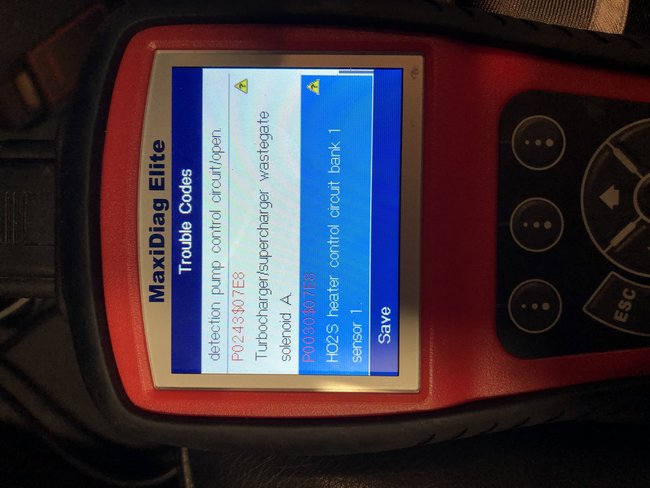

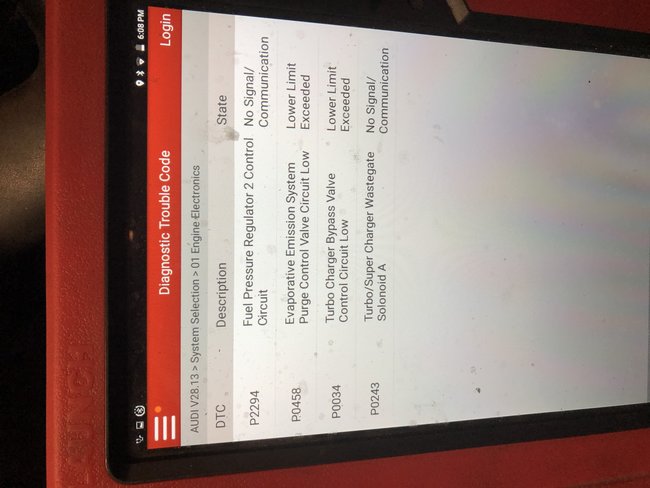

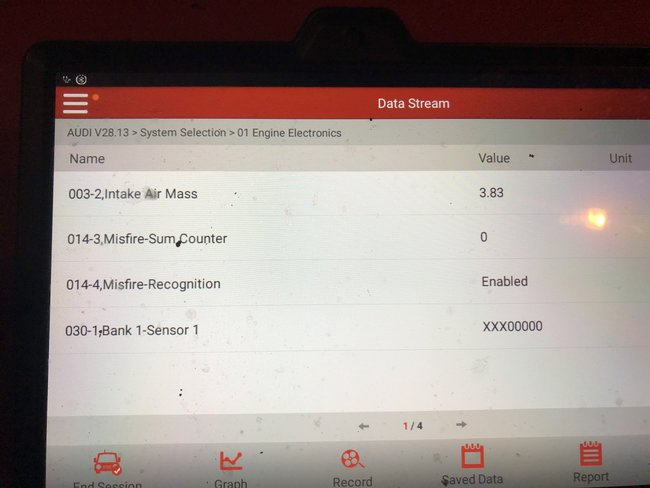

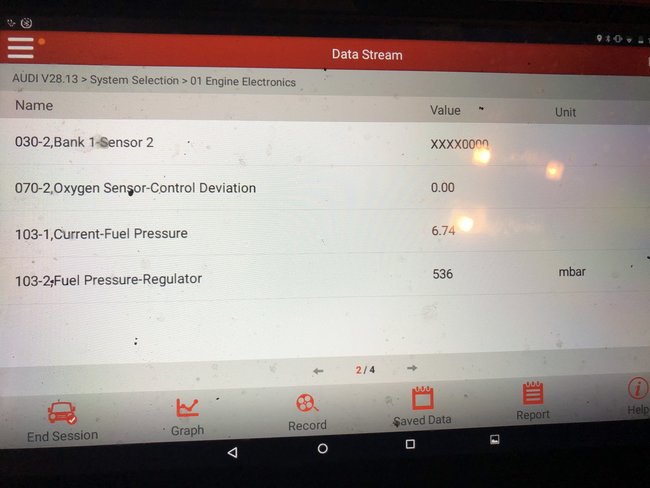

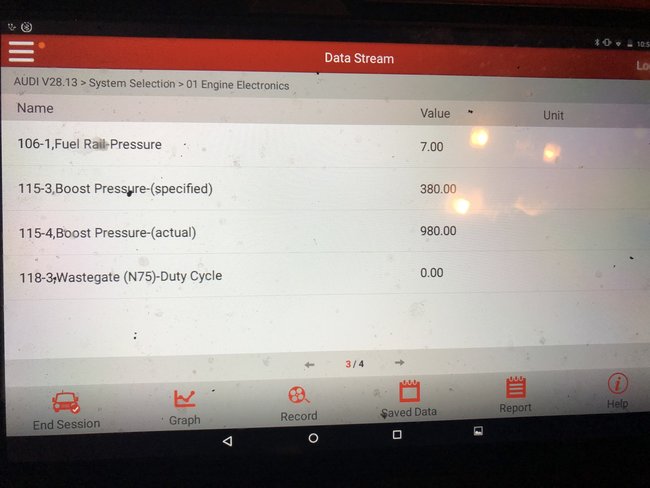

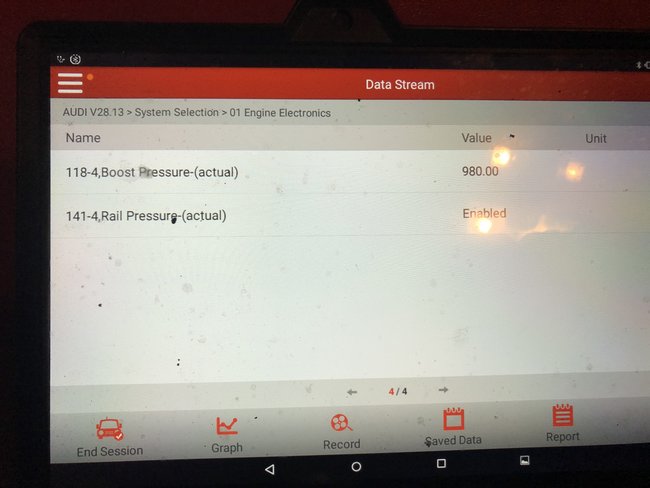

I'm starting to question if it is an issue with the intake runner intake position sensor. Not being there is making these test take long. I'm sorry for that. However, I need you to check the runner position sensor. Here are the directions. The attached pics correlate with the directions.

___________________________________

Intake Flap Motor/Intake Manifold Runner Position Sensor, Checking

Vehicle Powertrain Management Fuel Delivery and Air Induction Variable Induction System Variable Induction Control Valve Testing and Inspection Component Tests and General Diagnostics Intake Flap Motor/Intake Manifold Runner Position Sensor, Checking

INTAKE FLAP MOTOR/INTAKE MANIFOLD RUNNER POSITION SENSOR, CHECKING

Intake Flap Motor/Intake Manifold Runner Position Sensor, Checking

Use only gold-plated terminals when servicing terminals in the electrical harness connector of the Intake Flap Motor (V157)/Intake Manifold Runner Position Sensor (G336).

Special tools, testers and auxiliary items required

Multimeter.

Wiring diagram.

Test requirements

The Engine Control Module (ECM) ( J623) fuses OK.

Battery voltage at least 12.5 volts.

All electrical consumers such as, lights and rear window defroster, switched off.

Vehicles with automatic transmission, shift selector lever into position " P" or "N".

A/C switched off.

Ground (GND) connections between engine/transmission/chassis OK.

Ignition switched off.

Test procedure

- Perform a preliminary check to verify the customers complaint. Refer to => [ General Diagnosis ] See: Computers and Control Systems > Initial Inspection and Diagnostic Overview > General Diagnosis.

Start diagnosis

- Remove engine cover - arrows -.

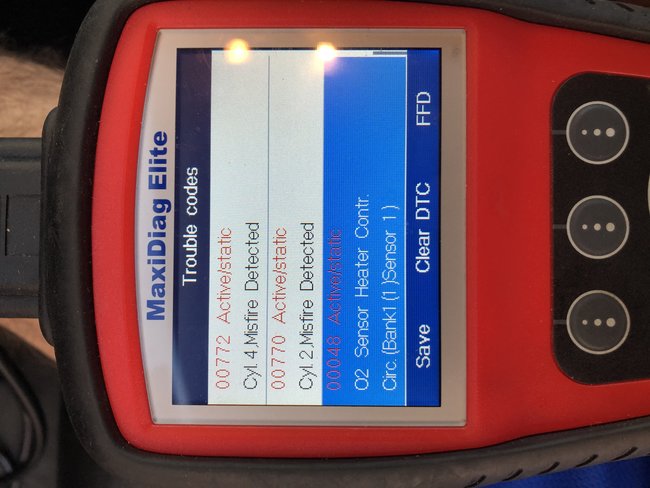

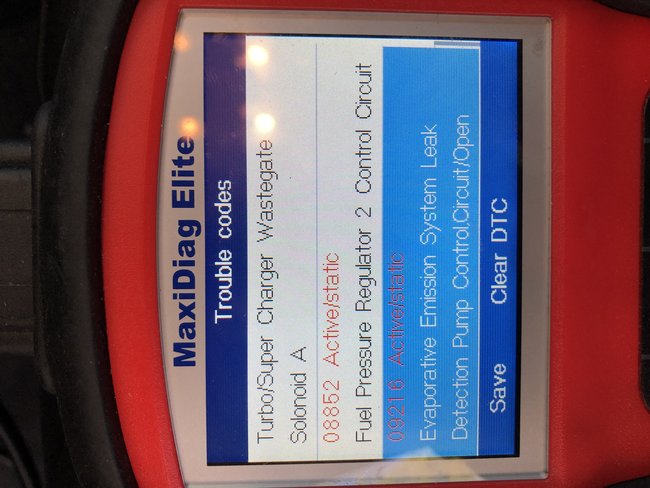

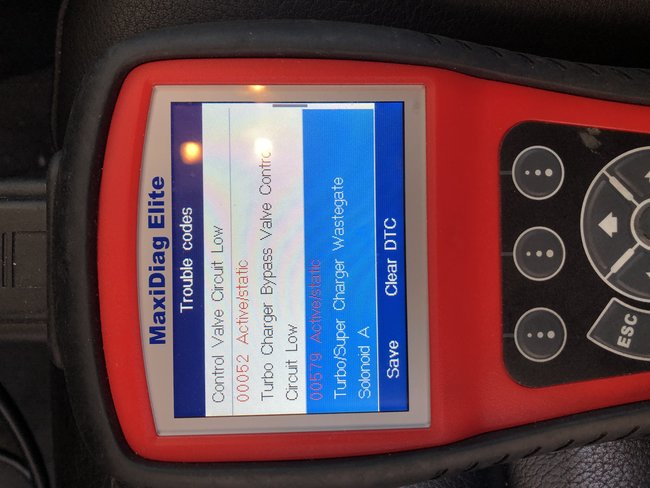

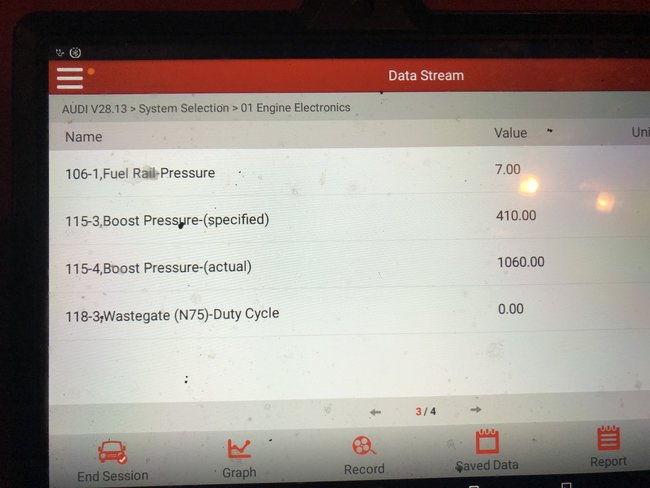

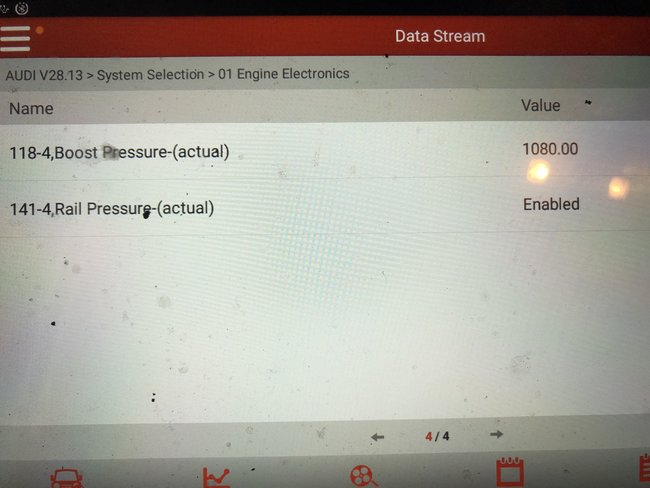

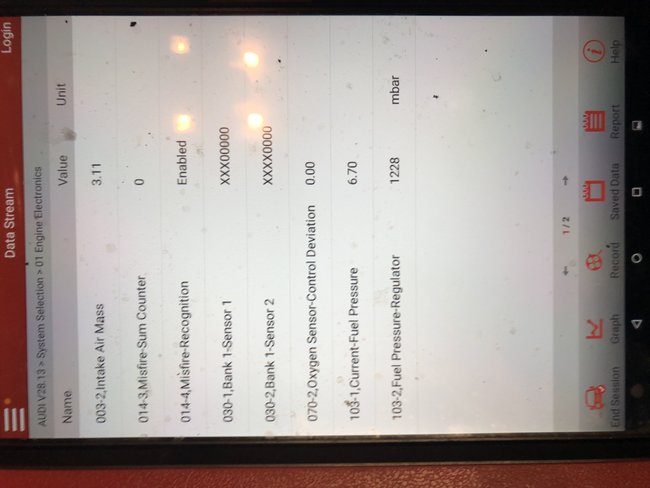

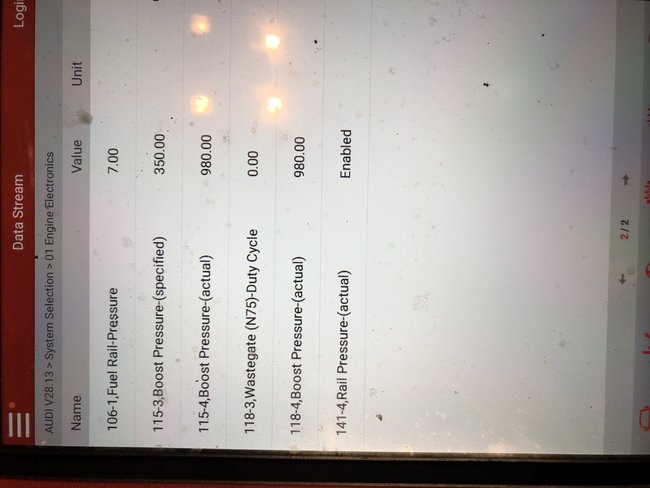

Pic 1

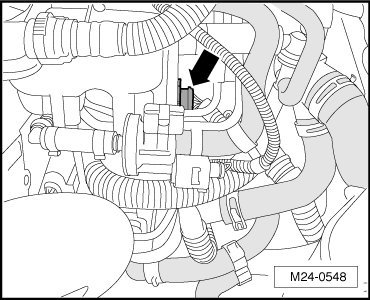

- Disconnect the Intake Flap Motor (V157)/Intake Manifold Runner Position Sensor (G336) electrical harness connector - arrow -.

Pic 2

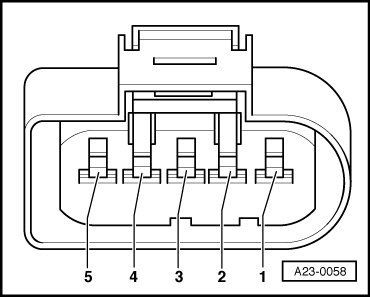

- Switch the ignition on.

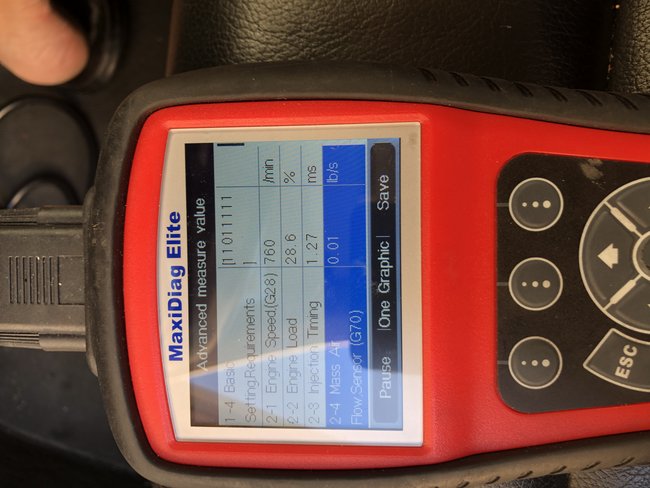

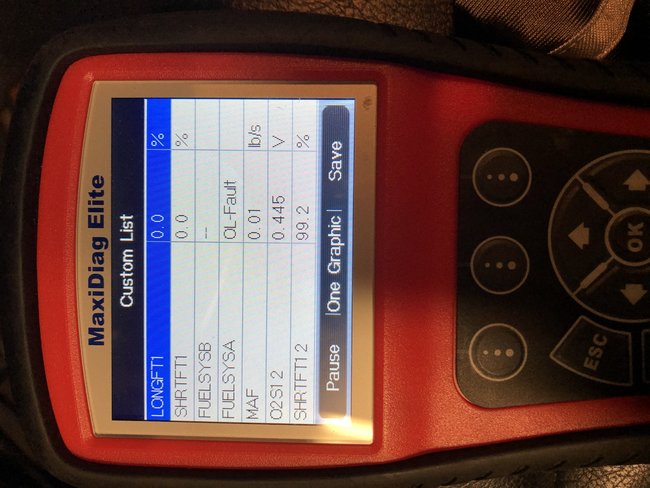

- Using a multimeter, check the Intake Flap Motor (V157)/Intake Manifold Runner Position Sensor (G336) electrical harness connector terminals 1 to 3 for voltage.

Pic 3

Specified value: about 5 V

- Switch ignition off.

If the specified value was obtained:

- Replace the Intake Flap Motor ( V157)/Intake Manifold Runner Position Sensor ( G336).

If the specified value was not obtained:

Checking wiring

If the manufacturers test box is being used. Perform the following step.

- Install the test box. Refer to Fuel Injection and Ignition Repair Information

If the manufacturers test box is not being used. Perform the following step.

- Remove the Engine Control Module (ECM) (J623). Refer to => [ Engine Control Module, Replacing ] See: Engine Control Module > Removal and Replacement > Engine Control Module, Replacing.

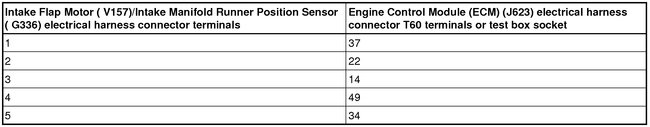

- Using a Multimeter, check the Intake Flap Motor ( V157)/Intake Manifold Runner Position Sensor ( G336) electrical harness connector terminals to the Engine Control Module (ECM) (J623) electrical harness connector T60 terminals for resistance.

Pic 4

Specified value: 1.5 ohms Max.

If the specification was not obtained:

- Check the wiring for an open circuit, a short circuit to each other, Battery (+), and Ground (GND).

- Check the electrical harness connector for damage, corrosion, loose or broken terminals.

- If necessary, repair the faulty wiring connection.

If no malfunction is detected in the wiring:

- Erase the DTC memory. Refer to => [ Diagnostic Mode 04 - Erase DTC Memory ] See: Computers and Control Systems > Scan Tool Testing and Procedures > Diagnostic Mode 04 - Erase DTC Memory.

- Perform a road test to verify repair.

If the DTC does not return:

Repair complete, Generate readiness code. Refer to => [ Readiness Code ] See: Computers and Control Systems > Monitors, Trips, Drive Cycles and Readiness Codes > Readiness Code.

- End diagnosis.

If the DTC does return and no malfunction is detected in the wiring and the voltage supply was not OK:

- Replace the Engine Control Module (ECM) (J623 ). Refer to => [ Engine Control Module, Replacing ] See: Engine Control Module > Removal and Replacement > Engine Control Module, Replacing.

- Assembly is performed in the reverse of the removal.

Final procedures

After repair work, the following work steps must be performed in the mentioned sequence:

1. Check the DTC memory. => [ Diagnostic Mode 03 - Read DTC Memory ] See: Computers and Control Systems > Scan Tool Testing and Procedures > Diagnostic Mode 03 - Read DTC Memory.

2. If necessary, erase the DTC memory. => [ Diagnostic Mode 04 - Erase DTC Memory ] See: Computers and Control Systems > Scan Tool Testing and Procedures > Diagnostic Mode 04 - Erase DTC Memory.

3. If the DTC memory was erased, generate readiness code. => [ Readiness Code ] See: Computers and Control Systems > Monitors, Trips, Drive Cycles and Readiness Codes > Readiness Code.

End of diagnosis

_______________________________

Let me know.

Joe

Images (Click to make bigger)

Monday, October 14th, 2019 AT 5:40 PM