Tuesday, October 29th, 2019 AT 10:43 PM

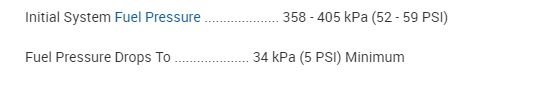

My car is having two issues where it will start after cranking for a while and giving it some throttle and then once it is idling when I go to rev it the engine wont go past 2,000 rpm's. So I checked fuel pressure and it had 42 at prime and 46-48 while running. So since fuel pressure was good I pulled one spark plug from the front of the motor and one from the back and both were lean (burnt white on the tips?). The back was worse than the front so I thought maybe clogged injectors sense it had good fuel pressure. I got some sea foam and ran it through the intake and the gas and it did nothing. I would like to not tear apart the whole motor to diagnose this issue so if anyone has had the same issue and found the fix or has an idea of what could be wrong lmk. I thought about the fuel pressure regulator but if that was bad it would not have good pressure at the rail? I do not know if you have any suggestions. Thank you, Austin