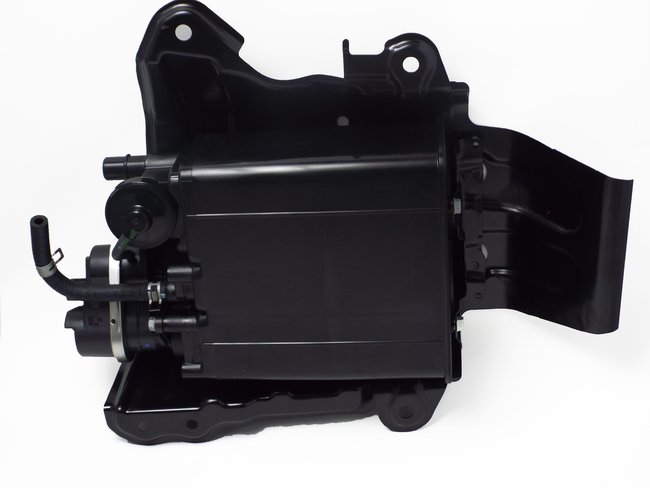

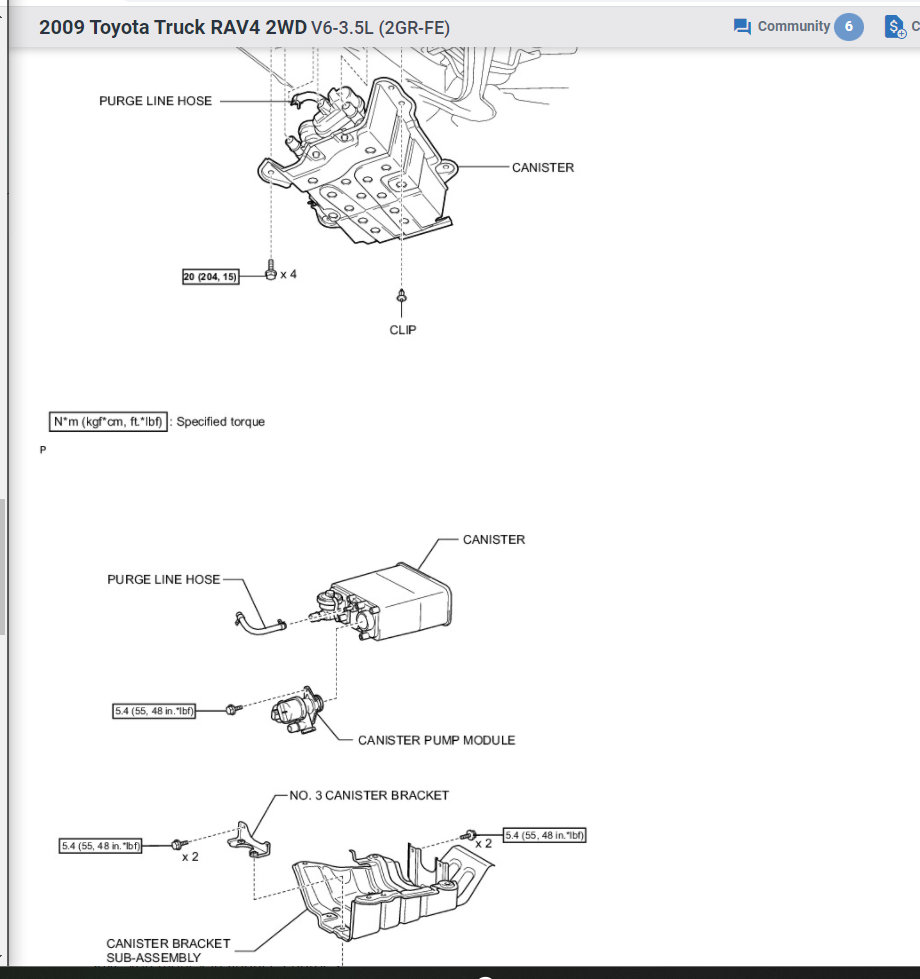

So that appears to be not only the canister but the pump module, and leak detection pump.

If that is the case, if these codes return after you clear them and drive the vehicle then I suspect this is an ECM issue at this point.

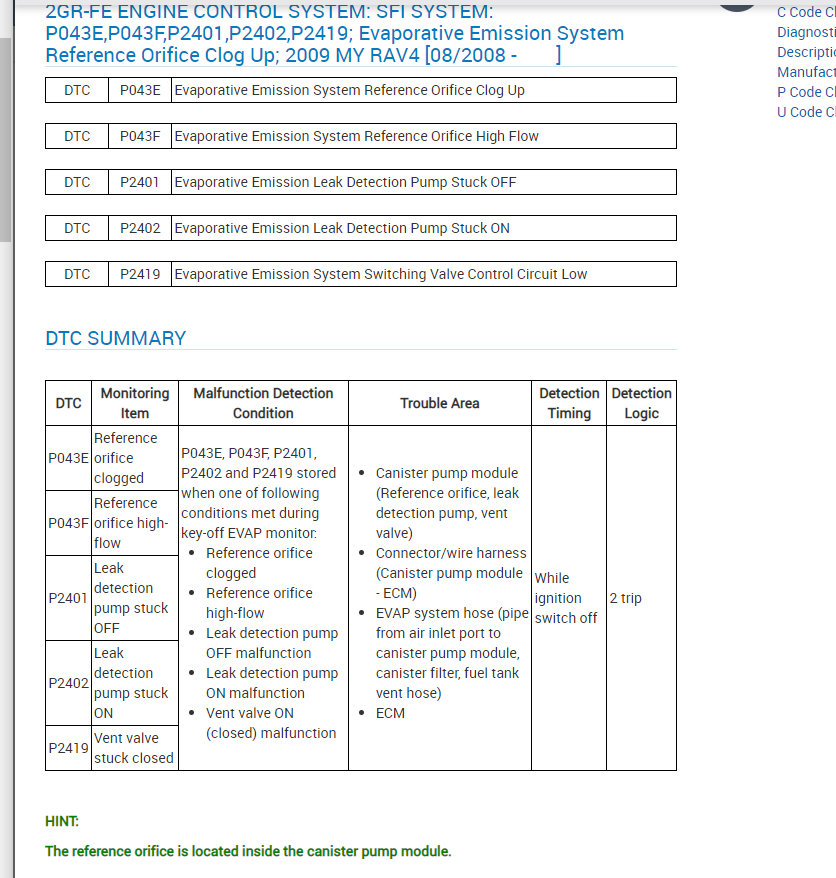

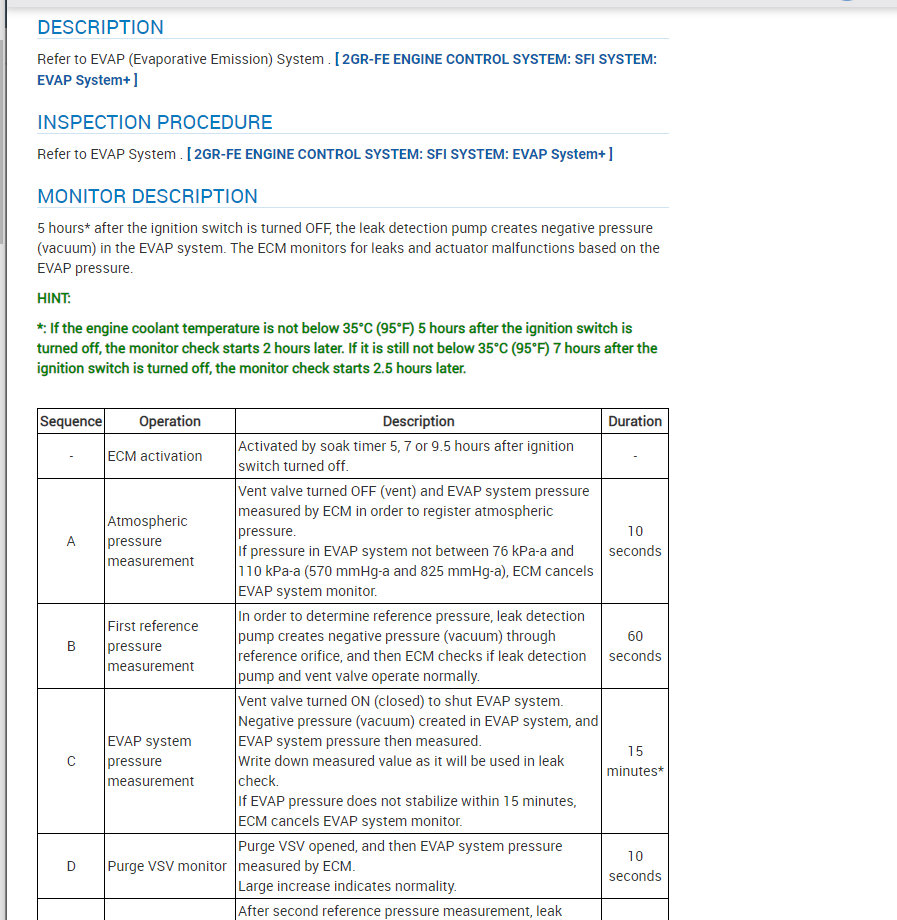

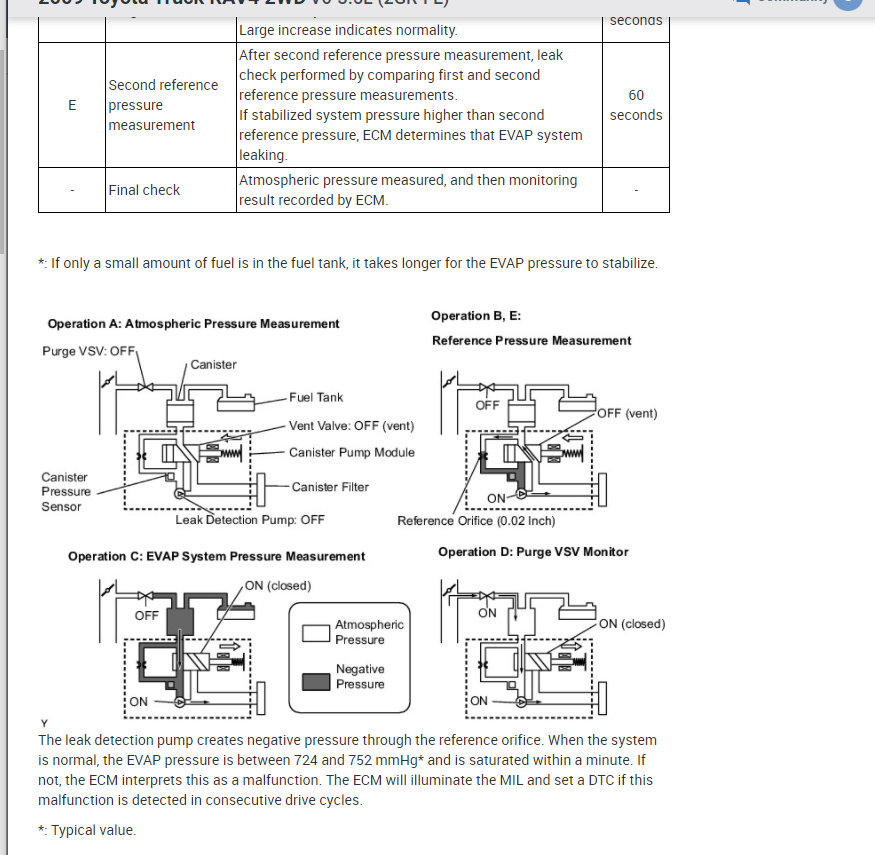

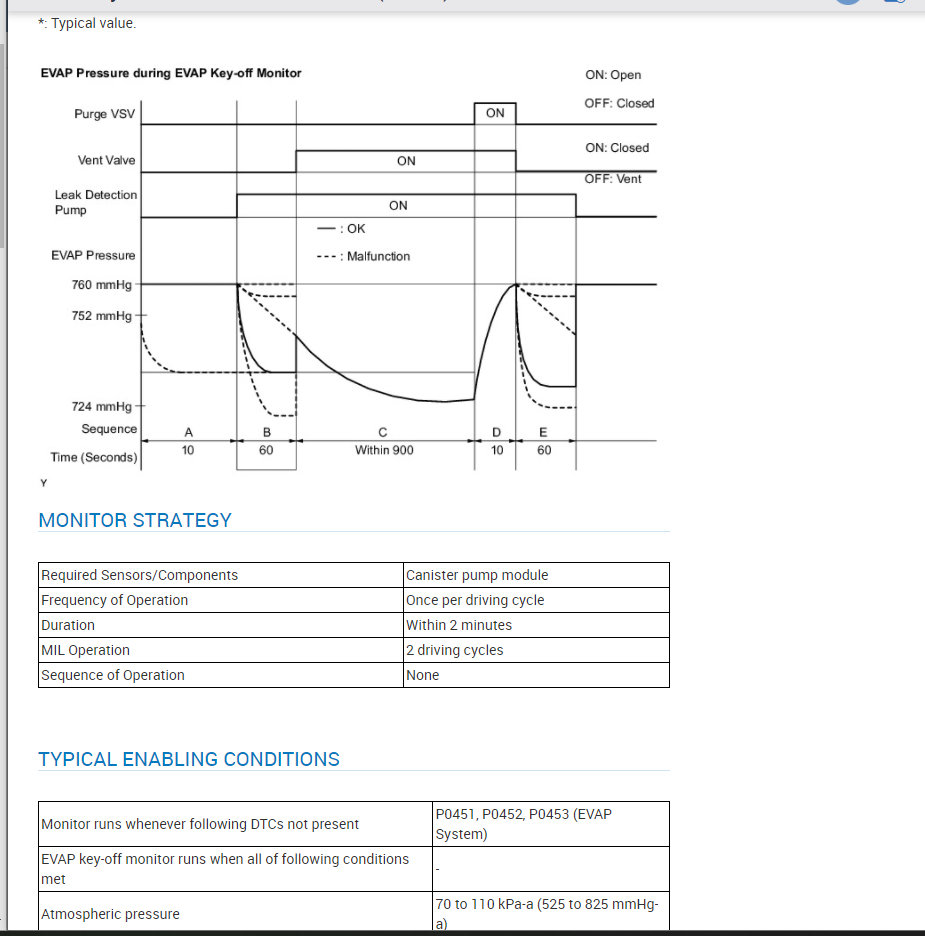

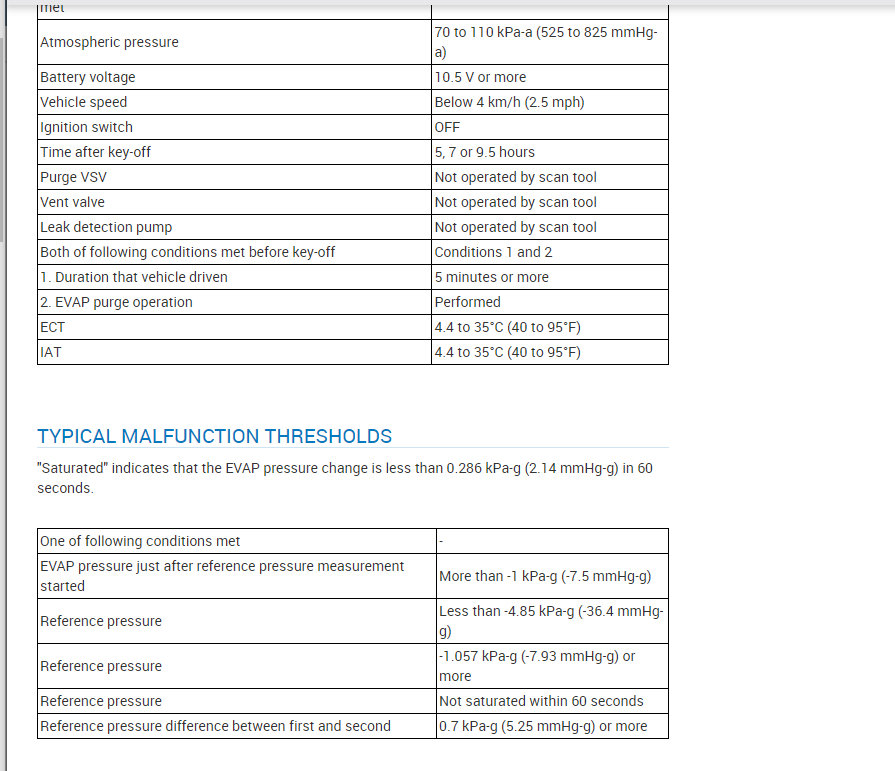

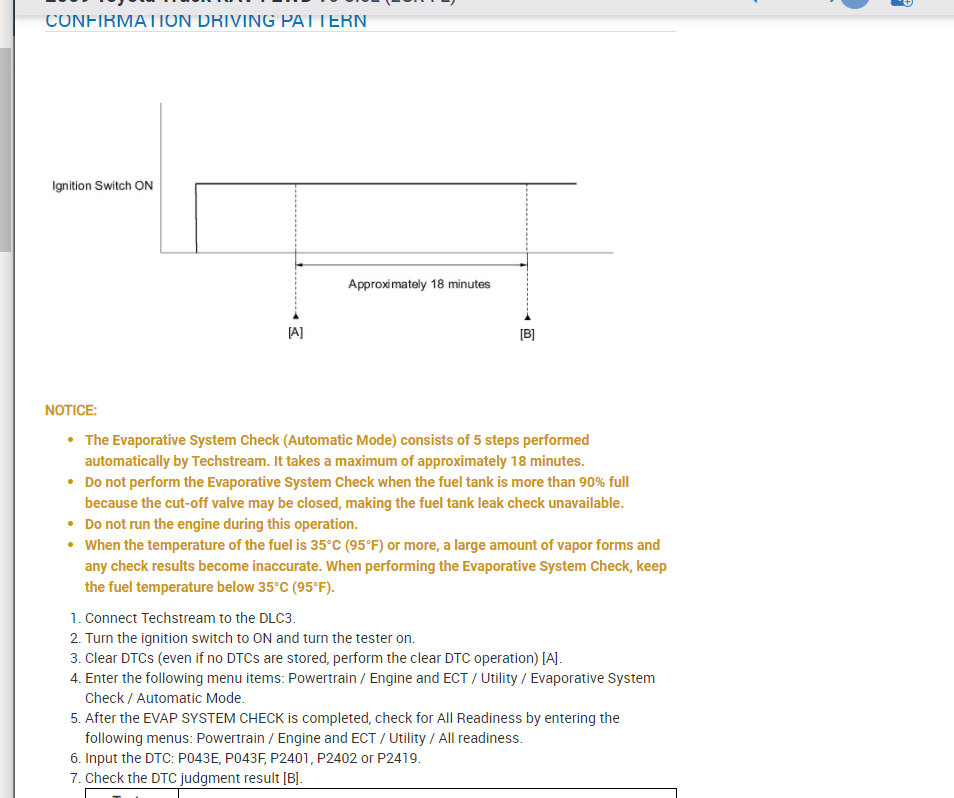

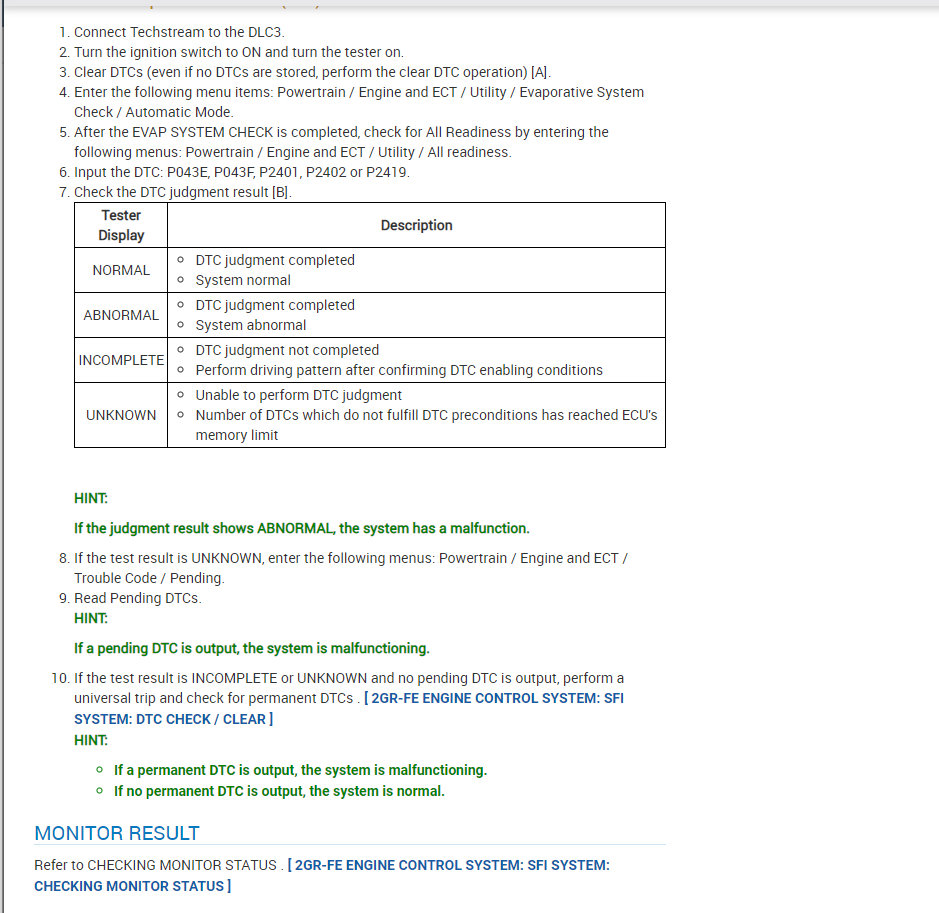

Basically, what happens is when you shut the engine off, the ECM watches this emissions system to try and make sure the pressure builds when it is sealed to make sure there are no leaks. It checks this at certain times, and it expects to see a certain pressure. If the pressure and time don't line up, then it sets these codes.

However, the fact that it is setting all of them points to a control issue.

If you think about it, how can it have high flow and a blocked orifice at the same time? Also, the leak detection pump is stuck on and off?

You can run through the testing but if it were me and you already replaced this assembly, I would be putting an ECM on it based on this info.

Image (Click to make bigger)

Saturday, October 9th, 2021 AT 3:17 PM