Hello,

Well agon813, I sure will do my best.

Okay, first, thanks for the info on the car. . ...I just want to make sure though, what I am looking at is a 2.3L VIN 3. So the 8th digit of your VIN is a 3. . .. . .yes?

Now you have a miss. Is this all the time, at idle, just while driving, when just starting out and the engine is cold, when it is just warm, all the time?

When was the last time you changed your air and fuel filter?

Did you clean your MAP sensor?

Was it missing and that is why you replaced the parts you did?

So you and I are saying the same thing, you

When you put new AC plugs in, you did gap them to .035 inches? NOTE: Check the gap specifications given on the Emissions Control Label. If the gap is different from what is listed here, use the information on the label.

The spark plug type for VIN 3 is AC FR3LSK - make sure you used these plugs. Other VINs use different ones, that is why I asked what the 8th digit was of your VIN.

Next, please go to Auto Zone or O'Reilly's and for FREE they can pull the codes to the car. Most important: Once they check your codes, if they find something and you don't get it fixed and need to get back with us, please make sure you tell us exactly what the code was, number and all. Example, if the code was E0568 O2 Sensor bad. Then make sure you give us all of that. While there for FREE also they can bring their tester out and check your battery, alternator and starter.

Now we may end up needing to check your fuel pressure also. . ...if you can, then get that done or you can wait until we gather the data from above.

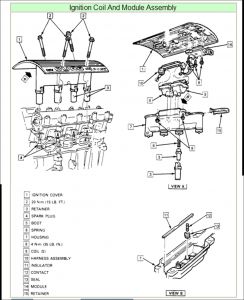

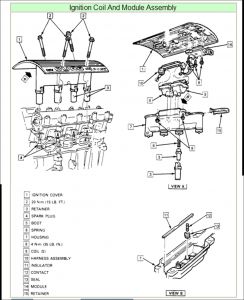

Okay, I don't have a good pic to show certain things so you may need to ask the parts department. I have attached the pic I am talking about.

First on the ignition cover, the bolts #2. . ..they look like they have rubber washers under them. Do they? If you are not sure then please call the parts department to verify. If yours has them on it make sure they are okay and metal is not touching metal.

Item #3, the retainers, did you make sure those were in good working condition - no tears, holes, burn through marks or burn marks.

Basically what we are checking for is a way for sparks to travel ANYWHERE other than your plugs. I worked a Grand AM not to long ago and the miss was the rubber washers were not installed. So as we go over these things, that is what we are looking for.

You replaced #4 - the plugs. . ...again, please make sure you used the correct plugs.

You changed the boots - #5

The springs #6- they are all in good working order and have good contact with the plugs.

Item #8 - more bolts - check for rubber washers - again, call the parts department to verify.

Item #9 you have replaced.

Item #10 - did you look that over really good for chaffed wires, burn marks, anything defective and the plug ends were clean - no cracks or any defects?

Item #11 - I don't show, but is this insulator rubber and is it in good working order, clean making contact in all of the required places?

Items 12 and 13 - are these in good working order - especially that 13, the seal?

Number 15, the retainer, no cracks or defects?

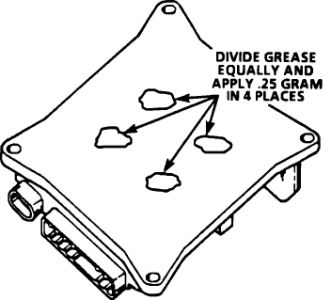

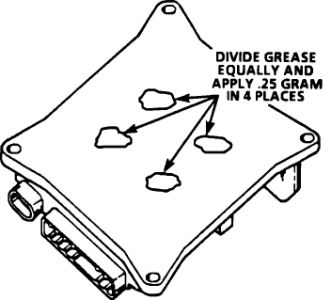

Now number 14 - the module - it may be heating up - pretty pricey so we will try to look at that last. I did want to provide you with what it does. As you see it sends a signal to the PCM so the correct spark and fuel injector fire. Special point here, I have attached a pic, there is supposed to be grease between it to help with the heat. White lithium grease. You can pick that up at AZ while you are there getting the free checks. I also attached the note on the module and coil about the grease.

PURPOSE

The Electronic Ignition (EI) control module monitors the crank sensor signals and based on these signals sends a reference signal to the PCM so that correct spark and fuel injector control can be maintained during all driving conditions.

NOTE

Do NOT wipe grease from module or coil if same module is to be replaced. If a new module is to be installed, a package of silicone grease will be included with it. Spread the grease on the metal face of the module and on the cover where the module seats. This grease is necessary for module cooling.

Okay, lots here - I need many questions answered and if you would get these checks done and make sure you check the things I asked. Then get back with me so we can get this miss gone.

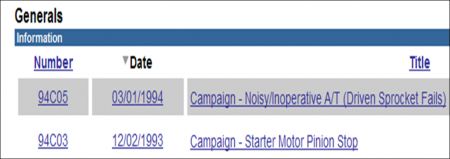

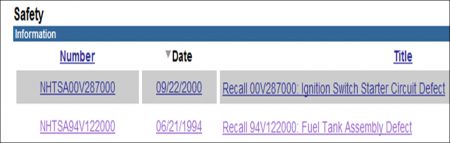

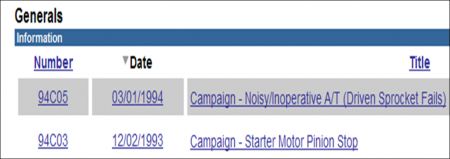

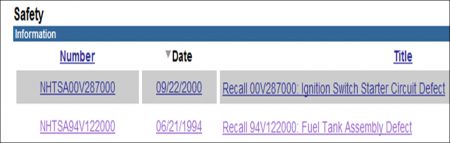

Last, looks like you may have some recalls on your vehicle. The dealer may fix these for free. Please contact the dealer service department, give them the VIN number of your car and have them check on these to see if they apply to you.

Wednesday, May 19th, 2021 AT 7:20 PM