Good evening,

This is a lean code. That means you may have a vacuum leak causing this or it could be something else.

https://www.2carpros.com/articles/repair-lean-mixture-codes-p0171-or-p0174-on-some-manufacturers

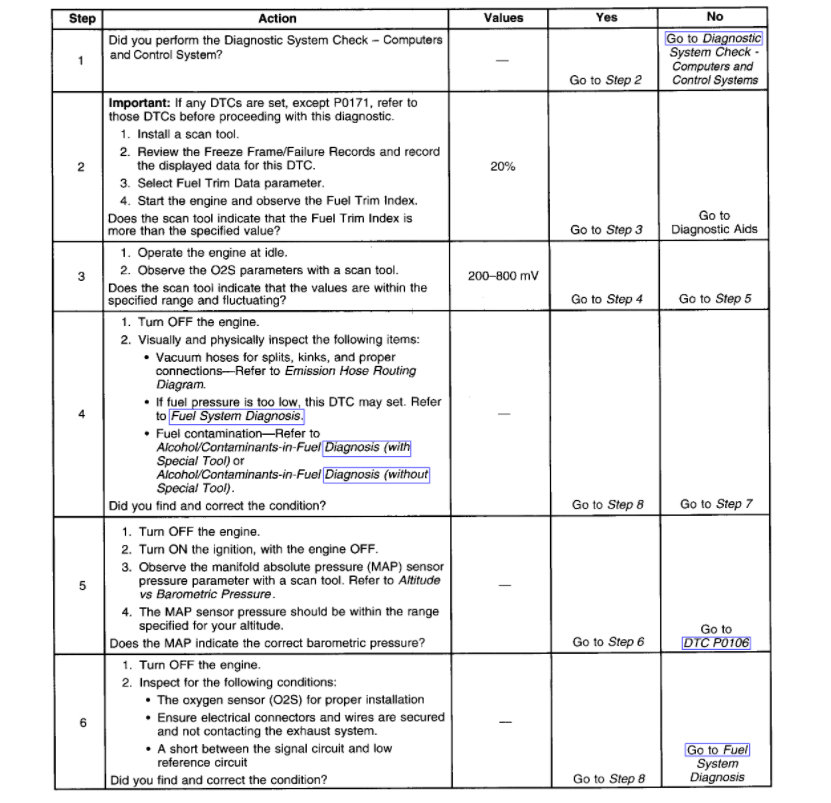

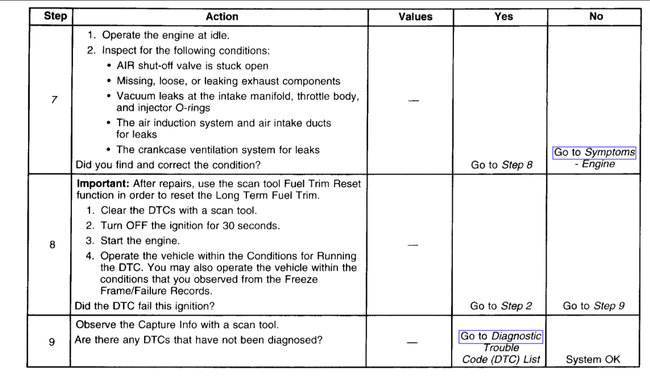

I attached the flow chart for testing for you. Follow the chart the best you can and let me know the results.

https://www.2carpros.com/articles/how-to-check-fuel-system-pressure-and-regulator

Roy

DTC P0171

CIRCUIT DESCRIPTION

The powertrain control module (PCM) controls the air/fuel metering system in order to provide the best possible combination of drivability, fuel economy and emission control. Fuel delivery is controlled differently during open and Closed Loop. During Open Loop, the PCM determines fuel delivery based on sensor signals, without oxygen sensor (O2S) input. During Closed Loop the PCM adds O2S inputs to calculate Short and Long Term Fuel Trim (FT) fuel delivery adjustments. Short Term FT values change rapidly in response to the heated oxygen sensor (HO2S) voltage signals. Long Term FT values change slower in response to trends in Short Term FT adjustments. Fuel Trim Index is the average of Short Term and Long Term FT and Purge Learn Memory based on engine speed and load. If the PCM detects an excessively lean condition, DTC P0171 sets.

CONDITIONS FOR RUNNING THE DTC

DTCs P0013, P0014, P0016, P0068, P0106, P0107, P0108, P0112, P0113, P0117, P0118, P0120, P0122, P0123, P0125, P0128, P0130, P0131, P0132, P0133, P0134, P0135, P0201-P0206, P0220, P0300, P0301-P0304, P0326, P0327, P0341, P0446, P0483, P0496, P0502, P0503, P0507, P0601, P0602, P0604, P0606, P0641, P0651, P1133, P1516, P1680, P1681, P2101, P2120, P2125, P2135, P2138, P2176 are not set.

The engine coolant temperature (ECT) is between 60-125°C (140-257°F).

The intake air temperature is between -25 and +150°C (-13 and +302°F).

The manifold absolute pressure (MAP) is above 6 kPa (0.9 psi).

The vehicle speed is less than 132 km/h (82 mph).

The engine speed is between 400-5,850 RPM.

The barometric pressure is more than 72 kPa (10.3 psi).

The fuel level is more than 10 percent.

CONDITIONS FOR SETTING THE DTC

The Fuel Trim Index is above 20 percent.

ACTION TAKEN WHEN THE DTC SETS

The control module illuminates the malfunction indicator lamp (MIL) on the second consecutive ignition cycle that the diagnostic runs and fails.

The control module records the operating conditions at the time the diagnostic fails. The first time the diagnostic fails, the control module stores this information in the Failure Records. If the diagnostic reports a failure on the second consecutive ignition cycle, the control module records the operating conditions at the time of the failure. The control module writes the operating conditions to the Freeze Frame and updates the Failure Records.

CONDITIONS FOR CLEARING THE MIL/DTC

The control module turns OFF the malfunction indicator lamp (MIL) after 3 consecutive ignition cycles that the diagnostic runs and does not fail.

A current DTC, Last Test Failed, clears when the diagnostic runs and passes.

A history DTC clears after 40 consecutive warm-up cycles, if no failures are reported by this or any other emission related diagnostic.

Clear the MIL and the DTC with a scan tool.

DIAGNOSTIC AIDS

Test for fuel contamination. Small amounts of water can be delivered to the fuel injectors and cause a lean exhaust indication. A lean exhaust indication can also be caused by too much alcohol in the fuel. Refer to Alcohol/Contaminants-in-Fuel Diagnosis (with Special Tool) or Alcohol/Contaminants-in-Fuel Diagnosis (without Special Tool). See: Computers and Control Systems > Component Tests and General Diagnostics See: Computers and Control Systems > Component Tests and General Diagnostics

The system will go lean if an injector is not supplying enough fuel.

A lean condition could be present during high fuel demand due to a fuel pump that does not pump enough fuel.

Review the Failure Records with a scan tool. If an intermittent condition is suspected, refer to Intermittent Conditions. See: Computers and Control Systems > Initial Inspection and Diagnostic Overview > Intermittent Conditions

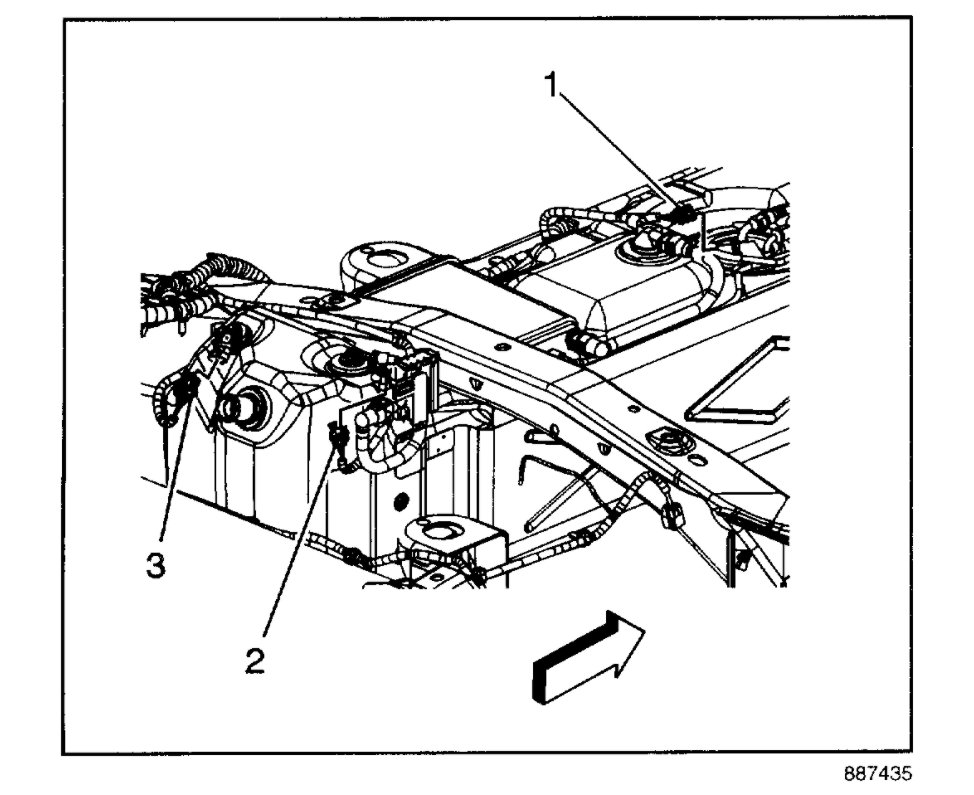

Images (Click to make bigger)

Friday, December 4th, 2020 AT 3:19 PM