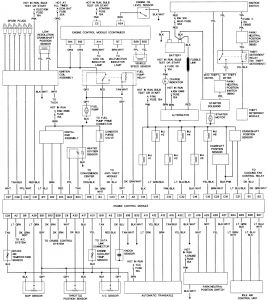

Ok you have spark thats good now we need to check fuel pressure since you cant hear the pump and compression fuel pressure Turn the ignition ON and check that pump pressure is 24-40 psi. (165-276 kPa)

Start the engine and allow it to idle. The fuel pressure should drop to 28-32 psi (193-221 kPa) due to the lower manifold pressure, please let me know reading on fuel pressure and compression also here is how to test compression

a screw-in type compression gauge is more accurate that the type you simply hold against the spark plug hole, although it takes slightly longer to use. It's worth it to obtain a more accurate reading. Follow the procedures given:

Warm up the engine to normal operating temperature.

Tag the spark plug wires and remove all the spark plugs.

Disable the fuel and ignition systems.

Remove the air cleaner assembly and fully open the throttle plates by operating the throttle linkage by hand or by having an assistant floor the accelerator pedal.

Coat the gauge threads with oil and screw the compression gauge into the no. 1 spark plug hole until the fitting is snug.

WARNING

Be careful not to crossthread the plug hole. On aluminum cylinder heads use extra care, as the threads in these heads are easily ruined.

Ask an assistant to depress the accelerator pedal fully. Then, while you read the compression gauge, ask the assistant to crank the engine two or three times in short bursts using the ignition switch. There should be four puffs per cylinder.

Read the compression gauge at the end of each series of cranks, and record the highest of these readings. Repeat this procedure for each of the engine's cylinders. Compare the highest reading of each cylinder to the compression pressure specification. The lowest cylinder reading should not be less than 70% of the highest reading. Examples follow:

NORMAL: Compression builds up quickly and evenly to the specified compression on each cylinder.

PISTON RINGS: Compression low on the first stroke, tends to build up on the following strokes, but does not reach normal. This reading should be tested with the addition of a few shots of engine oil into the cylinder. If the compression increases considerably, the rings are leaking compression.

VALVES: Low on the first stroke, does not tend to build up on following strokes. This reading will stay around the same with a few shots of engine oil.

HEAD GASKET: The compression reading is low between two adjacent cylinders. The head gasket between the two cylinders may be blown. If there is the sign of white smoke coming from the exhaust while the engine is running may indicate water leaking into the cylinder.

If a cylinder is unusually low, shoot about a tablespoon of clean engine oil into the cylinder through the spark plug hole and repeat the compression test. If the compression comes up after adding the oil, it appears that the cylinder's piston rings or bore are damaged or worn. If the pressure remains low, the valves may not be seating properly (a valve job is needed), or the head gasket may be blown near that cylinder. If compression in any two adjacent cylinders is low, and if the addition of oil does not help the compression, there is leakage past the head gasket. Oil and coolant water in the combustion chamber can result from this problem. There may be evidence of water droplets on the engine dipstick when a head gasket has blown.

Monday, February 2nd, 2009 AT 9:21 AM