since we purchased, in September, 2008. It is in beautiful condition, we look after it. Replaced A/C Everything! Catalytic Converter++ Fixed electrical problems in

'Alerts' on dash, separately, which were causing 'Check Engine' light to stay on. We have done Everything!

Check-Engine light came on again weeks ago, garages

told us it was, 'clogged catalytic converter', hadn't been 'welded properly causing a blockage, which, in turn, caused the the idle air control to malfunction.

I actually looked underneath the car when it was up at the garages

and I couldn't believe what I saw, the mechanics pointed out

the 'narrowing' and said to get it to a Good Cat shop, don't go back

to that place! Took it to Jeep Dealership because of distance/time/

Check Engine Code read, they couldn't figure it out!

Finally we had to get it towed to them, because car just cut out everywhere, you name it, Stop Signs, Traffic Lights and finally wouldn't start; towed! Jeep replaced the Idle Air Control Motor: $432.

Check engine light is back on again 2 days later!

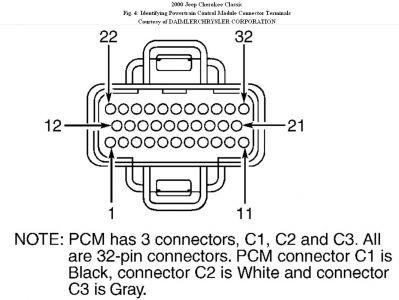

Back to Jeep, they replaced the Jeep Computer: $674.

We've already had the sensor replaced for same problems. Since we had the Jeep back the A/C only blows on highest setting! We've had Everything

replaced on A/C System! Check Engine light

came back on again, 3 days after replacing PCM!

We are desperate that this Jeep doesn't put us under

a bridge! Initially it was reported --2 Auto Shops-- that it was ' clogged catalytic converter / wrong installation problem causing the Idle Air Control system to 'overcompensate'. Jeep Auto Shop said: No, it's in fine, which is Odd, because we have had to fix Cat. Problems forever, including a second weld job!

We 'limped through the week, Jeep failing at stop signs and traffic lights

due to hectic schedules. Made Another appointment with Jeep for

this Thursday:

UPDATE:

Donated: $5:00 on:

Sunday, May 9th, 2010:

05/08/2010:

Garage Check:

"Complete OBD II Computer Diagnosis:

Indicate A Fault Code # PO505 ( Idle Air Control System)

Customers has just had Idle Air Control Valve Replaced at Dealership

Prior to Arrival --Including New PCM." Cost: $70.00

Exactly Same Code Presenting prior to Installing

New Parts indicated++ on File.

After New PCM was installed a week ago!

Front Right Passenger Side Window Started Operating --Up&Down

[It never had since 2008, when Jeep Purchased] Also Rear Back.

Left & Right Passenger windows and the A/C Blower has not been

'misbehaving' --I.E, Attempting to Only Blow on Highest Settings!

We 'felt' all along this was a 'wiring' snafu? --Possibly

caused by previous owner 'tweaking' wiring to 'quick-sell' --Sure,

enough, along We came!

At this juncture:

Is this 'Related' to the Cat. Problem [Refer above] mentioned by three garages

prior to the Jeep Dealership's throwing expensive parts at us and Not

fixing the problem; by the way Jeep said Cat was "a good job"

Not true, we have had awful problems and spent a lot of time and money

fixing them, including two re-weld jobs that we have Now been told

are 'bizarre' and that it needs re-doing from scratch! --Also that

because of that Cat. Job Jeep will not pass the smog-test due this

September 2010!

We have had A/C done, So many parts replaced, we believed

all along were due to 'false' readings due to previous owner

'tweeking' wiring etc.

Check Engine light's still on, and Jeep's Idle is 'Worse' staggering

at left turns and stops and traffic lights [Feels as if 'trying to

Fail] after all night in garage, then

running high idle, i.E, 'Attempting to 'jump brakes' !

Looked all over on line:

Could be a short on 'tach' wire leading to PCM

Though we still believe related to Cat job causing IAC to

overcompensate [Creating back-pressure]

UPDATE;

05/10/2010:

Jeep towed off Freeway/Hired Car:

Garage says Right Engine Mount Broken and put pressure

on 'shroud' over Fan: Fan blades cut into shroud as it had

'shifted' [Reason we

had to pull over and call the Tow, because of the terrific

grinding noise!]

Tomorrow Garage troubleshooting Check Engine light which

is still on: CODE PO505 has remained a 'constant' through

New IAC Motor and PCM!

Any idea What's going on? - Thank you for your response.

Monday, May 10th, 2010 AT 6:12 PM