Welcome to 2CarPros.

Here are the directions for removing the axle. The directions include removal of the lower ball joint. Tools needs are listed first. I will tell you that some of the axle nuts are a 32mm and others require an internal allen socket, which if I recall is 17mm. The nuts that hold the ball joint in place could be a 10mm or 13mm bolt. Truly, if they have ever been changed, different manufacturers supply new bolts and they come in different sized.

Here are the directions and the pictures attached correlate with the directions:

_______________________________________

Drive Axle, Removing and Installing, Triple Roller Joint AAR2600i

Special tools, testers and auxiliary items required

Drive Axle Wedge Tool (T10161)

Drive Shaft Remover (T10520)

Torque Wrench 1332 40-200Nm (VAG1332)

Removing

- Remove the drive axle bolt. Refer to [Drive Axle Threaded Connection, Loosening and Tightening ] See: Axle Shaft Assembly > Procedures > Drive Axle Threaded Connection, Loosening and Tightening.

The wheel bearing must not be under a load while the drive axle threaded connection on the wheel side is loose.

If the wheel bearings are under the load of the vehicle weight, the wheel bearing will be damaged. This reduces the service life of the wheel bearings.

The drive axle bolt may be loosened maximum 90° when the vehicle is standing on its wheels.

Vehicles without a drive axle must not be moved, otherwise the wheel bearing will be damaged. If a vehicle must be moved, be sure to note the following:

Install an outer joint in place of the drive axle.

Tighten the outer joint to 120 Nm.

- Loosen the wheel bolts.

- Raise the vehicle.

- Remove the wheel.

- Remove the lower noise insulation.

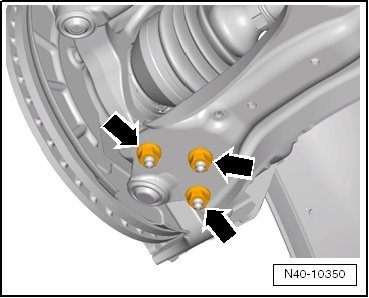

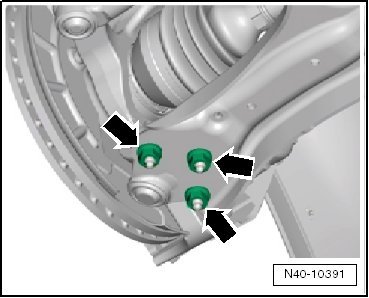

- Remove the nuts - arrows -.

Picture 1

- Remove both the wheel bearing housing and ball joint from the control arm.

- Pull drive axle out from wheel hub and secure it to body.

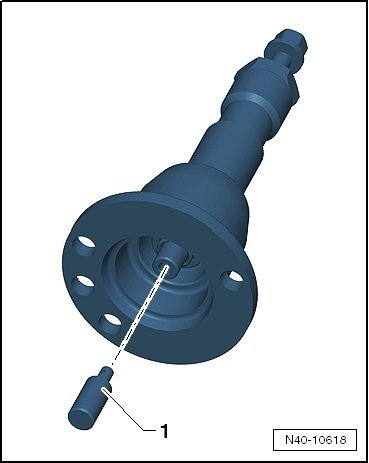

If the Drive Axle Cannot Be Pulled out of the Wheel Bearing, Then Drive Axle Can Be Pushed Out of the Wheel Bearing Using the Drive Shaft Remover (T10520).

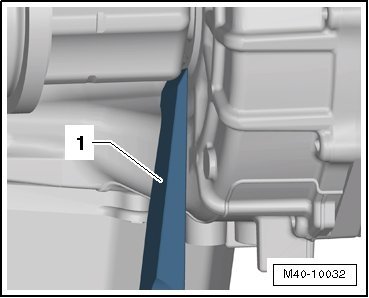

Before using the Drive Shaft Remover (T10520), make sure that the thrust piece - 1 - is installed.

Picture 2

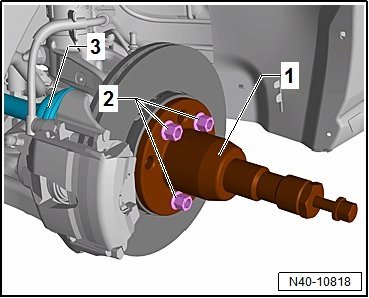

Using the Drive Shaft Remover (T10520) :

picture 3

- Secure the Drive Shaft Remover (T10520) - 1 - with three wheel bolts - 2 - on the wheel hub, so that the drive axle - 3 - can be pressed out.

- Follow the specified sequence.

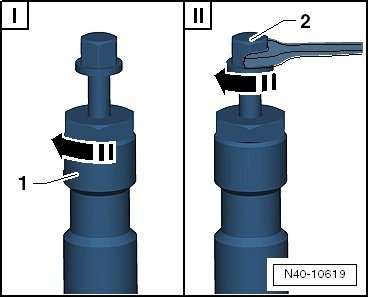

Picture 4

I Tighten the knurled nut - 1 - hand-tight.

II Only turn the bolt - 2 - using a wrench and press out the drive axle using the Drive Shaft Remover (T10520).

At the end of the tasks or to set back, the spindles must be brought back into the original position so that the hydraulic operation can be used.

- Place the Drive Axle Wedge Tool (T10161) - 1 - between the transmission housing and the triple roller joint.

- Using a rubber hammer, hit the inner joint on the Drive Axle Wedge Tool (T10161) and remove it from the transmission.

- Remove the drive axle.

Picture 5

Installing

Install in reverse order of removal. Note the following:

- Install new circlip into the groove of the joint shank.

- Engage the outer and inner splines of joint and transmission.

- Grab the drive axle by hand and push it into the joint up to the stop.

- Now slide joint piece into transmission with a tug.

The sliding part inside the linkage can be used for this tug. When doing this, do not pull the drive axle too far out of the joint.

Never use a hammer or mallet!

- Make sure the drive axle fits securely inside the transmission. The joint pulls against the resistance of the circlip.

When Checking, Only Pull on the Joint Piece and Not on the Drive Axle.

- Install the outer joint as far as possible into the wheel hub splines.

- Install the lower noise insulation.

- Attach the ball joint to the control arm - arrows -.

Picture 6

Make sure the ball joint boot is not damaged or twisted.

- Tighten drive axle bolt onto the wheel hub. Refer to [Drive Axle Threaded Connection, Loosening and Tightening ] See: Axle Shaft Assembly > Procedures > Drive Axle Threaded Connection, Loosening and Tightening.

Vehicle must not be standing on its wheels when doing this, otherwise wheel bearing will be damaged.

- Install the wheel and tighten. Refer to [Wheel Bolt Tightening Specifications ] See: Wheels and Tires > Mechanical > Wheel Bolt Tightening Specifications.

Tightening Specifications

Refer to [Overview - Lower Control Arm and Ball Joint ] See: Control Arm > Removal and Replacement > Overview - Lower Control Arm and Ball Joint

Refer to [Overview - Drive Axle ] See: Axle Shaft Assembly > Removal and Replacement > Overview - Drive Axle

Noise insulation bolts.

_________________________

Let me know if this helps or if you have other questions.

Take care,

Joe

Images (Click to make bigger)

Thursday, March 21st, 2019 AT 8:28 PM