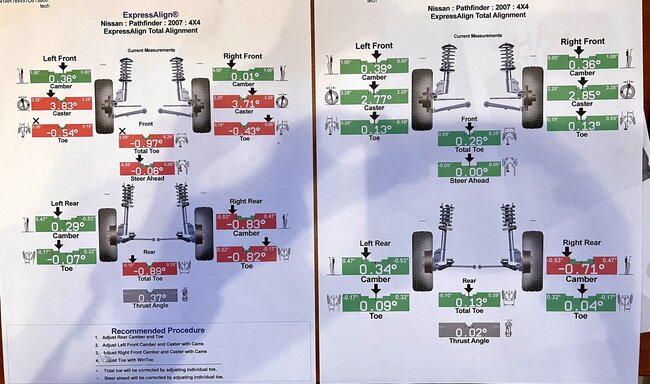

Dandy news. The first thing that stands out with the alignment is they have their computer set to read to hundredths of a degree. I did that with mine too. That shows your mechanic values precision over speed. The computers can be set to read to just tenths of a degree, then it rounds off the numbers. You lose the precision, but the adjustments take less work to get them to turn green, (in specs).

You came in with 0.01 degree "camber" on the right front. That wheel was standing perfectly straight, up and down. For reference, if you could imagine the wheel tipped out so far on top that it's laying flat on the ground, that would be 90.00 degrees. They tipped that wheel out a little, but not quite to perfect specs. I'd be very happy with that. I was the alignment specialist at a very nice family-owned Chrysler dealership through all of the 1990s, but I also aligned a lot of trade-in models. Chrysler's front-wheel-drive vehicles called for 0.30 degrees camber on the front, but there's a little more to the story. All roads slant to the right so water will run off. That "road crown" causes cars to drift to the right. One of two ways to make up for that is to make camber just a little higher on the left wheel. Tires want to roll in the direction they're leaning. I found that making the left wheel 0.06 degrees higher than the right one resulted in no complaints of pulling to either side. With old mechanical alignment equipment from the 1970s and back, the best you could hope for was to read camber to 1/8th, and maybe 1/16th of a degree. That's a far cry from today's computerized equipment that can read to 0.01 degree.

They left you with only 0.03 degree camber pull to the left, but it gets better. Caster can be very difficult to describe. Think of how the front fork of a bicycle is tilted rearward at the top. When you put weight on it, that makes the wheel squirt out straight ahead, and is what makes it possible to ride no-handed. On cars, the upper ball joint or the upper strut mount is rearward compared to the lower ball joint, as viewed from the side of the vehicle. Putting the vehicle's weight on it makes each wheel want to turn inward toward the center of the vehicle. They do that with so much force, you'd have a really hard time pulling one back straight by hand. It's when the two sides are connected by the steering linkage that the two forces offset each other.

Caster has very little effect on tire wear, but it is a pulling-to-one-side angle on all rear-wheel-drive vehicles and a few front-wheel-drive models. When it is a factor, they provide a means to adjust it, as they did on yours. The higher the caster, the harder it is to steer to one side, the faster the steering wheel returns to center on its own after going around a corner, and the less wander you get. As late as some 1960 models, especially heavy trucks, we used negative caster, meaning the upper ball joints were ahead of the lower ones, to make for very easy steering. The problem was it also caused a lot of steering wander which became a problem as we started driving faster on the better highways. That's why they went to positive caster, like a bicycle. Then, to make up for the much increased steering effort, they added power steering.

A few vehicles call for extremely high caster, as in around 11.00 degrees, but for the typical car, around 3.00 degrees is common. They lowered yours roughly a degree on each wheel to bring them into specs. You should find it easier to turn at low speeds now. But also notice the difference in caster, side-to-side, of 0.08 degrees. The right wheel wants to turn left just a fuzz harder than the left one wants to turn right. That very slight pull also offsets the effects of road crown. Caster pulls half as hard as does camber, so that's like having 0.04 degrees camber pull plus the original 0.03 degrees camber pull added together. It's very hard to get the settings that precise, so they must have spent a lot of time with this alignment. I'd call caster and camber "perfect".

"Total toe" is the sum of the toe readings on both wheels. You came in with minus 0.97 degrees. I had my computer set to read toe in inches, so my frame of reference will be off a little. I used to remember how the numbers related, but that's not important. The minus readings mean both front wheels were steering away from the vehicle's center. Left like that, the two front tires would develop a choppy pattern mainly on the inner edges of the tread. Think of holding a pencil upright with the eraser on the table. Press down a little, then drag it sideways. You'll see the "leading edge" scrubs and creates eraser crumbs, while the "trailing edge" bends and lifts up off the table, so no wear takes place there. That's what each block of the tire tread does with any toe out or too much toe-in.

Toe out also makes the vehicle overly sensitive to cross winds at highway speed. The wind pushes the car to the right, for example. That pushes more vehicle weight onto the right front tire. The car wants to follow the tire with the most weight on it, and the other one just scrubs along. Toe out means the right wheel is steering to the right a little and that's the way the vehicle will go. You have to constantly correct by steering to the left. That makes for a very tiring vehicle to drive.

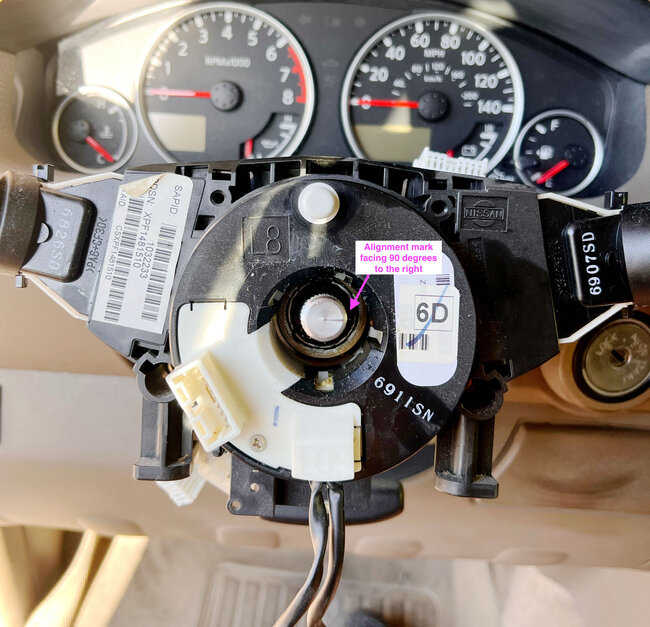

The fact that you came in with toe almost exactly equal on both front wheels suggests your preliminary method worked rather well, but it also points out the front wheels or the rear wheels are a little further apart. That's a common design issue, not a defect. Since your reference tires are different, the string method often used on race cars, and your laser system, can't possibly make all four wheels perfectly parallel. Camber and toe readings are always live, and any changes show up on the screen instantly. Caster can only be calculated by taking two camber readings, one with the wheels turned left and one with them turned right. When brought back to straight ahead is when the computer does the calculation. At this point it has no idea where the steering wheel is. That comes later. The point of this part of the story is if your two toe readings were this close to equal on the drive to the shop, your steering wheel would have been pretty close to centered too.

Moving to the rear, I wouldn't get too excited about the negative 0.71 degrees for right camber. A lot of models with independent suspension do call for some negative camber. The bigger concern is the negative 0.89 degrees toe out. You're going to have some choppiness on those tires. As best as I can recall, one degree is the same as 0.33 inches. If I have that right, that isn't a real lot of toe out, but I'm happy they fixed that at the right wheel.

Also note toe is not equal on both rear wheels. It's very common to find it's very much different between wheels, especially on vehicles with solid rear axles. The difference is called "thrust angle", meaning that's the overall direction the rear wheels are steering the back of the vehicle. When it's really bad, you see that as dog-tracking on the car you're following. What most people don't understand when they're sold a "four-wheel-alignment", even when nothing is adjustable on the rear, is all alignment computers look at toe on both rear wheels as the last step in the procedure, to determine exactly where to adjust toe on the two front wheels. That is what insures a perfectly straight steering wheel. A way to visualize this is to imagine looking down on a car with all four wheels perfectly straight and parallel to each other. Perfect alignment and no tire wear. Now imagine lifting the body up, rotating it slightly, and setting it back down on the wheels. You'd be driving sideways, and maybe looking out the side window to see where you're going. During the alignment, the computer would tell us to turn the rear wheels to make them parallel to the body, but that would appear to make the rear steer to one side. You'd have to correct by turning the steering wheel until, again, the front wheels were parallel to the rear wheels. But the last step in the alignment looks at where the rear wheels ended up, then we adjust the front ones to be parallel to them. The point of all this is it is done while the steering wheel is held perfectly centered. It will be the same when driving.

To boil this down, in a four-wheel-alignment, the computer uses the rear toe readings as the reference for the front wheels. Old mechanical equipment at first couldn't do that, so we often ended up with an offset steering wheel. Later, some equipment could take the rear wheels into account, but it was very cumbersome and time-consuming.

The final step, the two front toe readings of 0.13 degrees is perfect. Even if there was a difference of a few hundredths of a degree, you'd never see that in the steering wheel. From what I can see here, you got a very good alignment.

To check for the choppiness I described, rub your fingertips around the tire near the edges. The blocks of rubber will be shaped like little ramps. One way your fingers will glide smoothly over them. The other way you'll feel them catch on the raised, sharp edges. Often you can feel the same pattern by running your fingertips across the tread. Toe wear always affects both tires equally on that axle, even when just one wheel is misadjusted. Camber causes accelerated wear on just the inner or just the outer edge of the tread, and only on that one tire. When you have objectionable camber and toe wear on one tire, it gets a little more confusing until you see the numbers on the alignment computer.

Sunday, June 15th, 2025 AT 7:17 PM