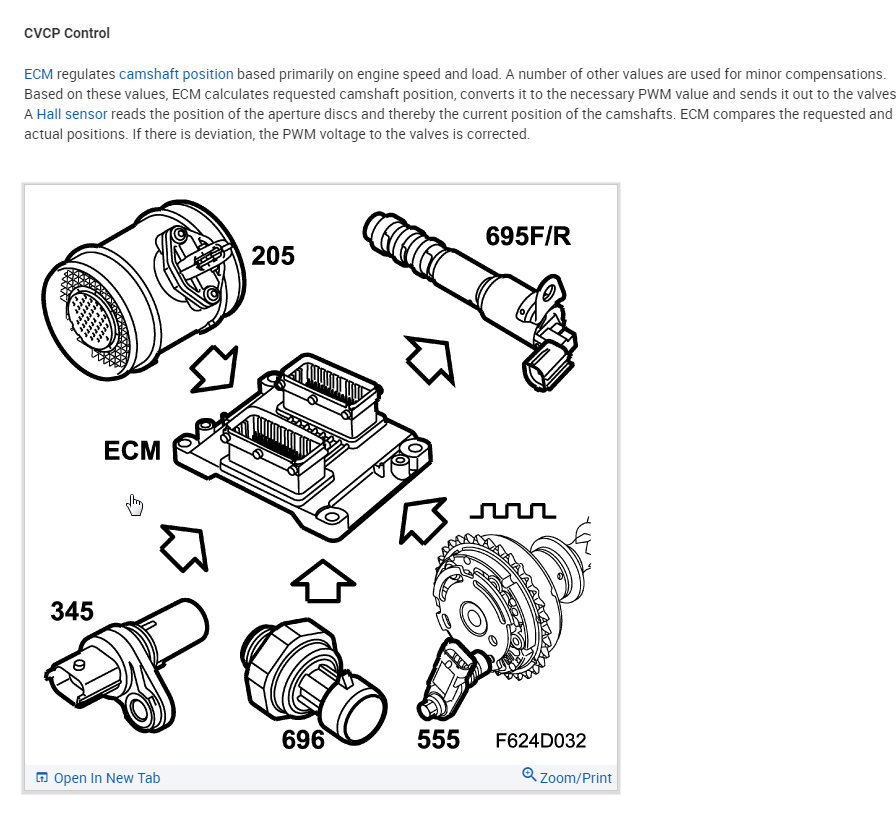

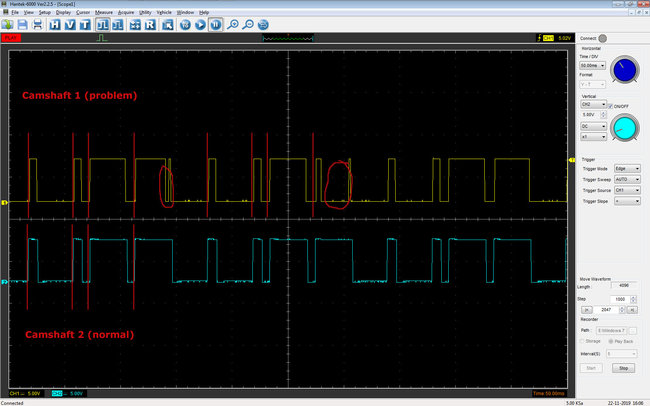

I then inspected the camshaft hole and it appears that one of the larger tooth's has a burr on it. Its not missing a chunk but has that burr. When I hook up my tech2 to the car I can test the intake cam angle on both banks. When I test bank 1 (the one with the code) I get no changes in the angle. That could be a result of the code being set and the ecm using default timing on that bank. This is a VVT cam phaser engine.

Any thoughts on what could be the issue here. I know these engines, which are similar to the 3.1 and 3.6 in CTS Cadillac's, are known for time stretch issues. Usually it is a different code.

Car seems to run fine aside from the dtc code.

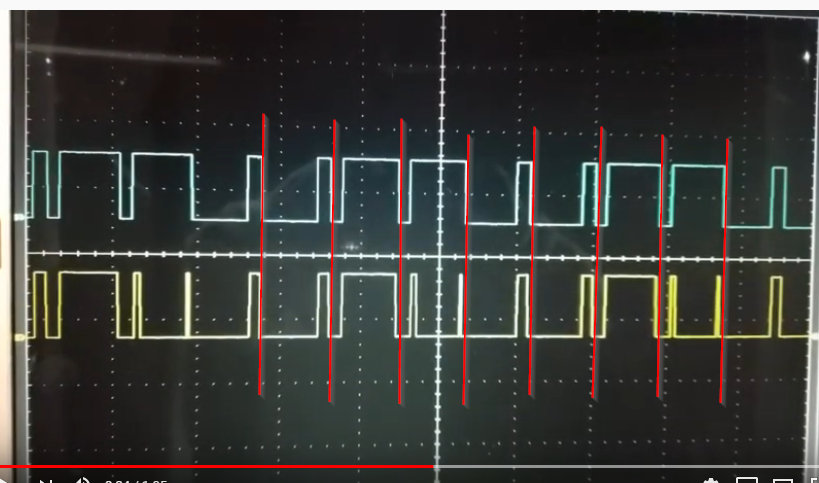

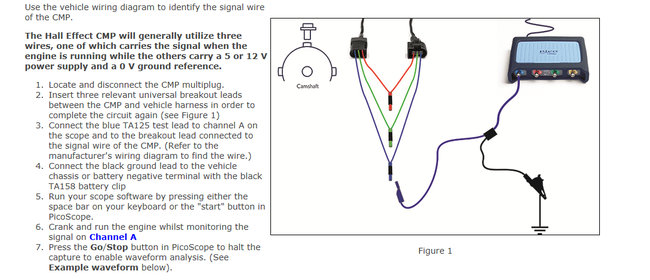

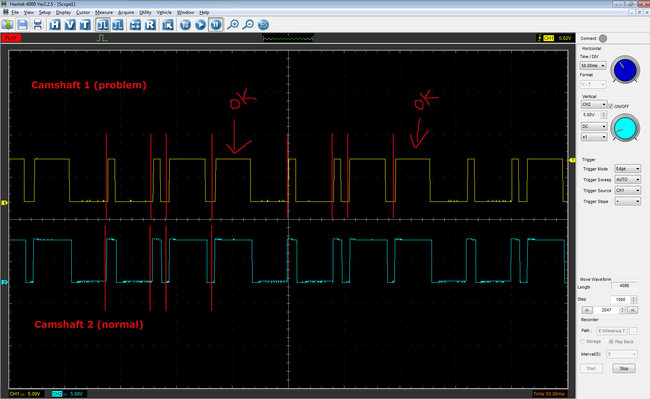

Video of my camshaft waveforms. Top blue is bank 2 which is okay and bottom yellow is bank 1. The second large tooth shows an issue on the scope.

Youtube of waveforms:

https://www.youtube.com/watch?v=KjcKs-ciVg4&feature=youtu.be

Intake Cam Angle Test:

https://www.youtube.com/watch?v=Gd3lbV1j1SI

Monday, November 11th, 2019 AT 11:36 PM