Thursday, July 5th, 2018 AT 9:45 AM

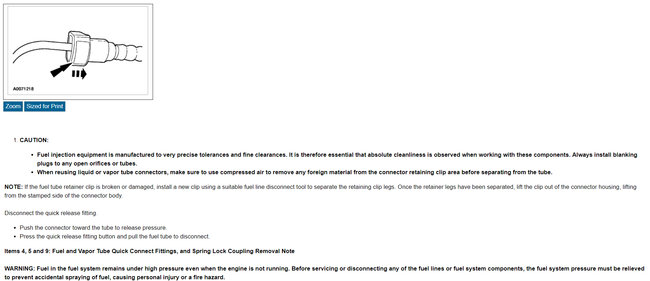

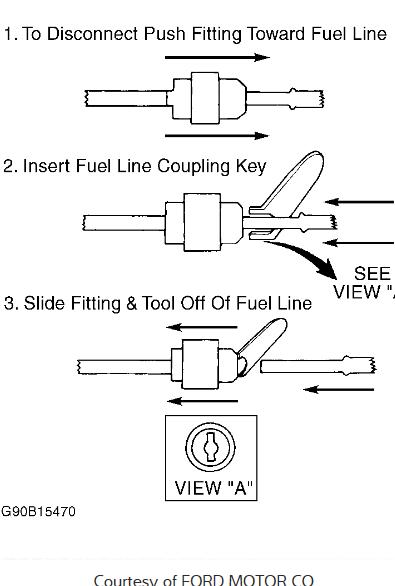

I cannot disengage the connectors at the fuel pump. All directions for this refer to the spring locking type and how to slide the tool down the line etc. Mine are not that type. I have the spring lock type on my fuel filter and have used the plastic tool there but fuel pump connectors are different. There is a rubber access port to the side of the connector but what tool is used to loosen these?