First of all, accelerated right front tire wear has always been a characteristic of Ford trucks and vans the salespeople didn't want you to know about. Sears used to buy a lot of these vehicles for their repair departments, and in their Auto Centers, we were always trying to correct that wear. What it boiled down to was to reduce that wear, replace the right front shock absorber with a stiffer one, and replace the right front strut rod, (aka, radius arm), bushing with a heavy duty one. Of course, to maintain a balanced ride and balanced braking, you would replace those parts on the left side too.

It's important to point out this applies to the twin I-beam front suspension system. A lot of larger Ford trucks used a single I-beam front suspension. Those were very strong but the trade-off was ride quality. To address the ride quality issue, they came up with the twin I-beam front suspension system. Now each front wheel could bounce over a pot hole without transmitting that bounce to the other wheel. The downside of this design is the horrible tire wear. It is even worse on the smaller Bronco 2 and Ranger. When you lift those vehicles on a hoist, you'll see both front tires tilt out a real lot on top, (Excessive positive camber). The opposite occurs when the front coil springs sag from age. With the older "short-arm, long-arm", (SLA) suspension used on all large cars in the '60s and '70s, the geometric relationship of the two control arms and the spindle kept the wheels pretty straight as the car went up and down over bumps in the road. With the twin I-beam system, the wheels run through an arc and are constantly tipping in and out on top as you drive. This system is where correct suspension ride height is most critical. Due to the age of your truck, it is pretty much a certainty it is sitting too low in front.

Chrysler has used adjustable torsion bars since 1960, and by the early to mid '90s, GM and Ford started using them too on their trucks. One advantage is they're easily adjustable, but the vehicle should be bounced a few times after making an adjustment, but before taking new measurements. The adjusting bolts are easier to turn if the front of the vehicle is raised up to remove some of the weight on the torsion bars.

If you have coil springs in front, those are relatively easy to replace with regular hand tools. I can find the procedure and post it for you if you need it.

The drawings show Ford's procedure for measuring ride height. It looks complicated, but Chrysler has done it this way for a long time. You're simply taking a measurement from two different places in relation to ground, then subtracting the difference. This method eliminates the variable of different tire sizes. All repair shops have a small book that lists every model and year, where to take the measurements, and what they should be. Those aftermarket procedures may be simpler and faster, but they will give multiple specs to cover different tire sizes. You might consider stopping in at a tire shop and asking to see that book.

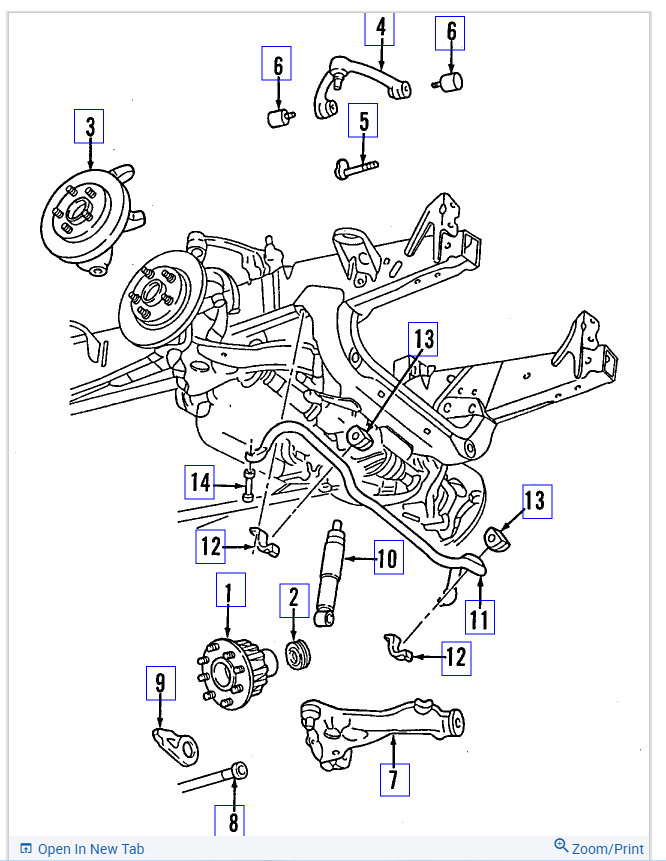

According to this diagram, your truck uses the SLA suspension system, so the vehicle design should not be an issue with accelerated tire wear. Keep in mind that with sagged ride height, camber can still be set to specs on the alignment rack, but the geometric relationship between the control arms and spindle will be drastically different. This is where you will have greatly increased tire wear even though the alignment appears to be perfect. This wasn't a problem at the dealership when working on vehicles only a few years old, but trade-ins were often old enough to come in with sagged springs. Fortunately the owner where I was the alignment specialist understood this issue and allowed me to replace sagged springs before doing the alignment.

Once you've checked out the ride height issue, it is also possible the truck is just out-of-alignment. You appear to understand "camber". If you do not know what "caster" is, let me know and I'll draw something to explain it. Camber has the biggest effect on pulling to one side. Both front tires want to roll in the direction they're leaning. A camber spec is specified that provides the best tire wear, but there is a small range that is acceptable. We always set the left camber slightly more positive than the right side to offset "road crown". That's where roads tilt to the right so water runs off. Camber is also what affects tire wear on the inner or outer edge of the tread. Also, camber only affects wear on that one tire, although camber can be out-of-adjustment on both wheels.

While camber affects tire wear and pulling, caster basically only affects pulling.** Here again there is a range of adjustment that is acceptable, and it's important that caster be the same on both wheels. On rear-wheel-drive vehicles, one degree of caster difference side-to-side has the same effect as half a degree camber difference. That means a camber pull can be offset with a caster pull the other way. Negative camber on the right front wheel will lead to accelerated wear on the inner edge of the tire, but if there's enough caster pull to the right, you may not notice any pull when you let go of the steering wheel. If these two differences are bad enough, you'll see the steering wheel oscillate left and right as the front end goes up and down over a bump such as a railroad crossing.

Part of the alignment problem comes from having to move the two pivot points of the upper control arm. It's real easy to set the first wheel, but then it can be very tedious and frustrating to match camber and caster exactly, on the other side. Ford's engineers came up with a dandy idea to address that. They used a two-piece upper control arm on the right side. All we had to do was adjust camber where we wanted it, then the outer half of the control arm could be slid forward or backward to adjust just caster without messing up camber. Unfortunately they dropped the ball as far as replacement parts. The upper ball joint was cast as part of the control arm, and you could not buy that two-piece arm. All they provided was the single-piece arm, so it was back to "adjust and measure, adjust and measure", over and over, until we were happy.

To address what it sounds like is that dreaded "death wobble", that is never caused by worn steering or suspension parts, but worn parts will allow that to become worse. This used to be common on older Jeeps that called for really high caster, but it can happen on any large truck. Another characteristic of caster is it is what causes the steering system to return to center on its own after you turn a corner. When caster is too high, the steering system returns to center so fast that it overshoots and goes the other way. The scrubbing action of the tires on the road surface accentuate this, so it keeps on going back and forth until you slow down. The majority of trucks also use a steering damper to prevent this wobble. That is essentially a shock absorber laying on its side, but it pulls apart and squeezes together equally hard in both directions. One end is connected to the cross member, and the other end to the steering linkage near the center of the truck. The first thing to look at is if the oil has leaked out of the damper. If it is wet, just like would be seen with a defective shock absorber, replace the unit and be careful that the mounting bolts will not interfere with the steering linkage. The next thing is to have the alignment checked. If caster is near the high end of its acceptable range, ask to have it lowered to reduce the chance of the death wobble occurring. All professionals will inspect all of the steering and suspension parts before performing an alignment. The reputable mechanics will not take your money or agree to do the alignment if they know a worn part or anything else will not solve a problem or provide the best tire wear possible.

** I must mention that for all practical purposes, caster has no effect on tire wear. One characteristic of caster is it causes the wheels to tilt in the direction you're turning. For that reason, for any mechanic taking the ASE Suspension and Alignment certification test, the correct answer is "caster does affect tire wear". In actual practice, that type of wear is most pronounced when turning sharply in a parking lot. In real life, even if caster is adjusted wildly wrong, its affect on tire wear will not be noticeable.

Monday, June 8th, 2020 AT 6:35 PM