STARTER -1999 Ford Ranger

Page 1 of 3

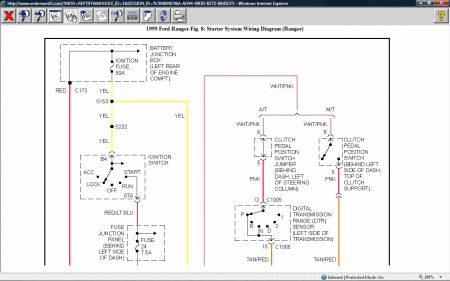

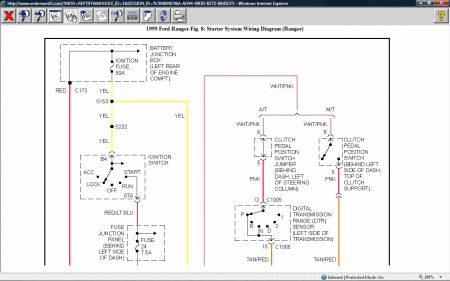

ENGINE DOES NOT CRANK

1.Verify battery condition. Battery voltage should be 12 volts or more. Load test battery at approximately one-half cold cranking amperage rating. See load tester manufacturer's instructions. If battery voltage is less than 12 volts or loaded battery voltage is less than 9.6 volts, service battery or charging system as necessary. 2.Measure voltage between positive battery post and engine block where negative battery cable is connected (on 4.0L negative battery cable grounds to starter mounting stud). If battery voltage exists, go to next step. If battery voltage does not exist, clean and tighten ground cable connections and recheck. If battery voltage still does not exist, replace negative battery cable. 3.Measure voltage between positive battery post and starter motor case. If battery voltage exists, go to next step. If battery voltage does not exist, clean starter motor mounting flange and ensure starter motor is properly installed. 4.Turn ignition switch to LOCK position. Measure voltage at between starter motor solenoid terminal "B" and ground. See Fig. 3 . If battery voltage exists, go to next step. If battery voltage does not exist, clean and tighten positive cable connections and recheck. If battery voltage still does not exist, replace positive battery cable.

Fig. 3: Identifying Starter Solenoid Terminals Courtesy of FORD MOTOR CO.

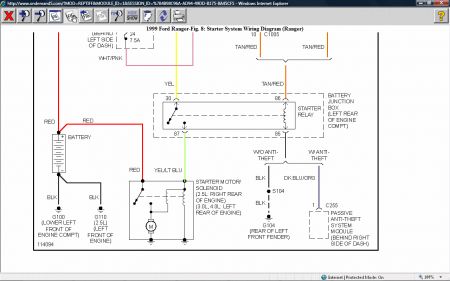

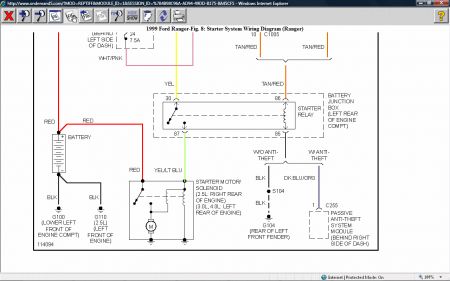

5.Connect remote starter switch between starter motor solenoid terminals "B" and "S". Engage remote starter switch. If starter engages and engine cranks, go to next step. If starter motor does not engage, repair or replace starter motor as necessary. See STARTER MOTOR under REMOVAL & INSTALLATION. If starter motor engages but engine does not crank, check for engine mechanical failure (hydrolock, seized, transmission locked up, etc.). If mechanical failure does not exist, repair replace starter motor as necessary. 6.Disconnect Yellow/Light Blue wire from terminal "S" at starter solenoid. See Fig. 3 . Measure voltage at Yellow/Light Blue wire with ignition switch in START position. If battery voltage does not exist, go to next step. If battery voltage exists, repair poor connection at terminal "S" at starter solenoid and check system operation. 7.Turn ignition off. Remove starter relay from battery junction box. Measure voltage at terminal No. 86 (Tan/Red wire) at starter relay socket with ignition switch in START position. See Fig. 4 . If battery voltage exists, go to next step. If battery voltage does not exist, go to step 12 .

Fig. 4: Identifying Starter Relay Socket Terminals

Courtesy of FORD MOTOR CO.

8.Turn ignition off. Measure voltage between starter relay socket terminal No. 30 (Yellow wire) and ground. If battery voltage exists, go to next step. If battery voltage does not exist, check fuse No. 5 for open. If fuse is okay, repair open in Yellow wire or battery junction box between starter relay and fuse No. 5. See WIRING DIAGRAMS . 9.Measure resistance between ground and starter relay socket terminal No. 85 (Black wire). If resistance is 5 ohms or less, go to next step. If resistance is greater than 5 ohms, and vehicle is not equipped with anti-theft system, repair open in Black wire between battery junction box and ground. If resistance is greater than 5 ohms, and vehicle is equipped with anti-theft system, check resistance of Dark Blue/Orange wire (or Pink/Orange wire) between battery junction box and PATS module. If resistance is greater than 5 ohms, repair open in Dark Blue/Orange wire (or

8/16/2008

STARTER -1999 Ford Ranger

Page 2 of 3

Pink/Orange wire). See WIRING DIAGRAMS . If resistance is less than 5 ohms, check anti-theft system operation. See appropriate ANTI-THEFT SYSTEMS article in ACCESSORIES & EQUIPMENT. 10.Ensure Yellow/Light Blue wire is disconnected from terminal "S" at starter. Measure resistance between ground and starter relay socket terminal No. 87 (Yellow/Light Blue wire). If resistance is greater than 10,000 ohms, go to next step. If resistance is 10,000 ohms or less, repair short to ground in Yellow/Light Blue wire between battery junction box and starter. See WIRING DIAGRAMS . 11.Measure resistance in Yellow/Light Blue wire between starter motor solenoid terminal "S" connector and starter relay socket terminal No. 87. If resistance is greater than 5 ohms, repair open in Yellow/Light Blue wire between battery junction box and starter. See WIRING DIAGRAMS . If resistance is 5 ohms or less, replace starter relay and check system operation.

NOTE: On vehicles equipped with automatic transmission, Clutch Pedal Position (CPP) switch is substituted with a CPP jumper.

Fig. 5: Identifying Clutch Pedal Position (CPP) Switch/Jumper Harness Connector

Courtesy of FORD MOTOR CO.

12.Disconnect Clutch Pedal Position (CPP) switch (M/T) or CPP jumper (A/T) harness connector. Both components are located on clutch pedal bracket. Ensure anti-theft system is disabled (if equipped). Measure voltage at terminal No. 6 (White/Pink wire) at CPP switch/jumper harness connector C206 with ignition switch in START position. See Fig. 5 . If battery voltage does not exist, go to next step. If battery voltage exists, go to step 19 . 13.Turn ignition off. Remove and inspect fuse No. 24 (7.5-amp) in fuse junction panel. If fuse is okay, go to next step. If fuse is blown, go to step 15 . 14.Measure voltage at input side of fuse No. 24 with ignition switch in START position. If battery voltage does not exist, go to step 22 . If battery voltage exists, repair open in White/Pink wire between fuse junction panel and CPP switch/jumper harness connector. See WIRING DIAGRAMS . 15.Measure resistance between ground and terminal No. 6 (White/Pink wire) at CPP switch/jumper harness connector. If resistance is greater than 10,000 ohms, go to next step. If resistance is 10,000 ohms or less, repair short to ground in White/Pink wire between fuse junction panel and CPP switch/jumper harness connector. See WIRING DIAGRAMS . 16.Remove starter relay from battery junction box in engine compartment. Measure resistance between ground and terminal No. 5 (Pink wire) at CPP switch/jumper harness connector. If resistance is greater than 10,000 ohms, replace fuse No. 24 and check system operation. If resistance is 10,000 ohms or less, go to next step (A/T models) or repair short to ground in Pink and/or Tan/Red wires between starter relay and CPP switch/jumper harness connector (M/T models). See WIRING DIAGRAMS . 17.Disconnect Digital Transmission Range (DTR) sensor harness connector. Measure resistance between ground and terminal No. 5 (Pink wire) at CPP sensor/jumper harness connector. If resistance is greater than 10,000 ohms, go to next step. If resistance is 10,000 ohms or less, repair short to ground in Pink wire between DTR sensor and CPP switch/jumper harness connector. See WIRING DIAGRAMS . 18.Measure resistance between ground and terminal No. 10 (Tan/Red wire) at DTR sensor harness connector. See Fig. 6 . If resistance is greater than 10,000 ohms, adjust DTR sensor and check system operation. See DIGITAL TRANSMISSION RANGE (DTR) SENSOR under

8/16/2008

STARTER -1999 Ford Ranger

Page 3 of 3

ADJUSTMENTS. If starter still does not crank, replace DTR sensor. If resistance is 10,000 ohms or less, repair short to ground in Tan/Red wire between DTR sensor and starter relay. See WIRING DIAGRAMS .

Fig. 6: Identifying Transmission Range Sensor Harness Connector Terminals

Courtesy of FORD MOTOR CO.

19.Remove starter relay from battery junction box in engine compartment. Measure resistance between terminal No. 5 (Pink wire) at CPP switch/jumper harness connector and terminal No. 86 (Tan/Red wire) at starter relay socket. See Fig. 4 and Fig. 5 . If resistance is 5 ohms or less, replace CPP switch/jumper switch or jumper. If resistance is greater than 5 ohms, go to next step (A/T models) or repair open in Pink and/or Tan/Red wire between CPP switch/jumper harness connector and starter relay (M/T models). See WIRING DIAGRAMS . 20.Disconnect Digital Transmission Range (DTR) sensor harness connector. Measure resistance in Pink wire between terminal No. 5 at CPP switch/jumper harness connector and terminal No. 12 at DTR sensor harness connector. See Fig. 5 and Fig. 6 . If resistance is 5 ohms or less, go to next step. If resistance is greater than 5 ohms, repair open in Pink wire between CPP switch/jumper harness connector and DTR sensor. See WIRING DIAGRAMS . 21.Measure resistance in Tan/Red wire between terminal No. 86 at starter relay socket and terminal No. 10 at DTR sensor harness connector. If resistance is 5 ohms or less, adjust DTR sensor and check system operation. See DIGITAL TRANSMISSION RANGE (DTR) SENSOR under ADJUSTMENTS. If starter still does not crank, replace DTR sensor. If resistance is greater than 5 ohms, repair open in Tan/Red wire between starter relay and DTR sensor. See WIRING DIAGRAMS . 22.Disconnect ignition switch harness connector. Measure voltage between terminal B4 (Yellow wire) at ignition switch harness connector and ground. See Fig. 7 . If battery voltage exists, go to next step. If battery voltage does not exist, repair open in Yellow wire between ignition switch and battery junction box. See WIRING DIAGRAMS .

Fig. 7: Identifying Ignition Switch Harness Connector Terminals

Courtesy of FORD MOTOR CO.

23.Remove fuse No. 24 (7.5-amp) from fuse junction panel. Measure resistance in Red/Light Blue wire between output side of fuse No. 24 and terminal STA at ignition switch harness connector. See Fig. 7 . If resistance is 5 ohms or less, replace ignition switch. See appropriate STEERING COLUMN SWITCHES article in ACCESSORIES & EQUIPMENT. If resistance is greater than 5 ohms, repair open in Red/Light Blue wire between ignition switch and fuse junction panel. See WIRING DIAGRAMS .

8/16/2008

Saturday, August 16th, 2008 AT 8:51 PM