Ok, appears the IAC is good.

I will ask the other techs to post test proceedure for the other components and the thoughts on your problem. I don't have access to my to get the proceedures. I am out of state for a few day.

In mean time if you can test the TPS (Throttle Position Sensor).

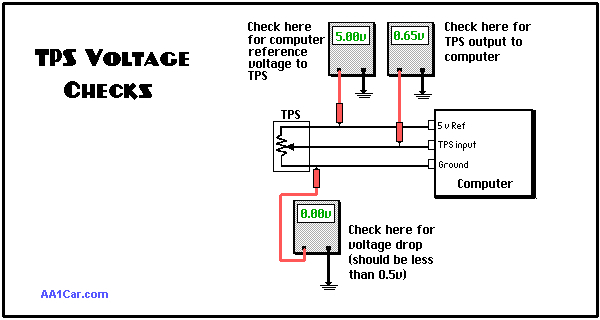

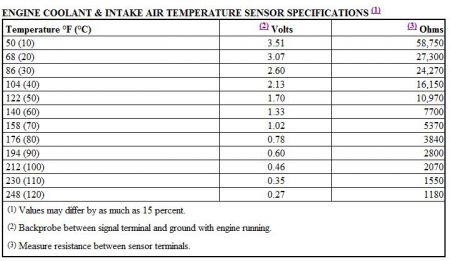

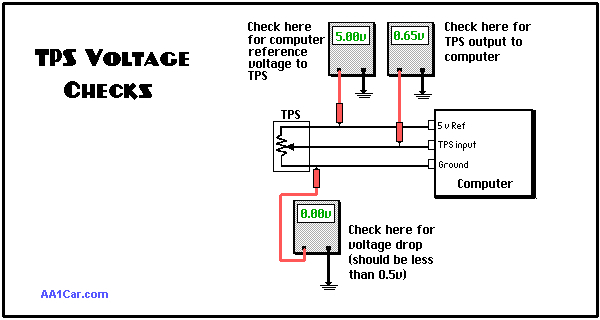

You can measure the sensor's output voltage by packprobing the sensor conenctor with a voltmeter. First, check for the presence of voltage at the TPS with the key on. The TPS cannot deliver the proper signal if it does not receive reference voltage from the computer. Refer to a wiring diagram for the reference connection and look for 5 volts.

The second check is the base voltage reading. Compare the voltage reading to the manual specifications. TPS voltage values are often specified to the nearest hundredth of a volt, so if the base TPS voltage reading is not within .05 volts of the specified value, adjustment may be needed (if it is adjustable). If it is not adjustable and the reading is out of specifications, replace the sensor.

The third check is for the proper voltage change as the throttle opens and closes. Voltage should rise smoothly from about 1 volt to a maximum of 5 volts at wide open throttle. No voltage rise or skips in the reading means the sensor needs to be replaced.

Image (Click to make bigger)

Wednesday, January 27th, 2010 AT 7:58 PM