You need to test for fuel pressure .. As OBX has stated it sounds like you have a faulty FRP or FRT .. it could also be getting a weak signal occassionaly from the CKP

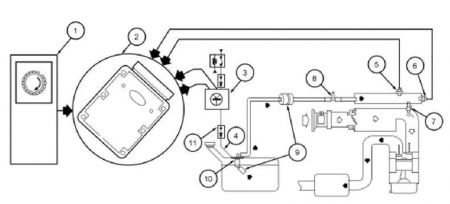

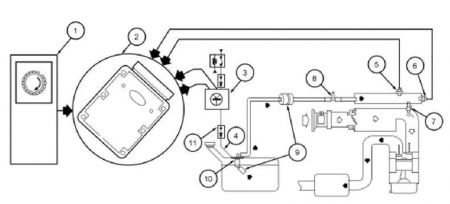

Electronic Returnless Fuel System

The electronic returnless fuel system consists of a fuel tank with reservoir, the fuel pump, the fuel rail pressure (FRP) sensor, the fuel filter, the fuel supply line, the fuel rail temperature (FRT) sensor, the fuel rail, the fuel injectors, and a Schrader valve/pressure test point. Operation of the system is as follows:

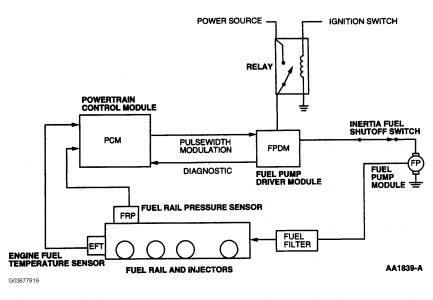

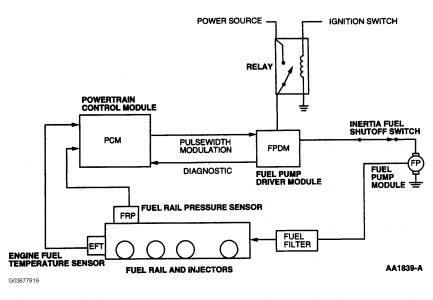

The fuel delivery system is enabled during crank or running mode once the PCM receives a crankshaft position (CKP) sensor signal.

The fuel pump logic is defined in the fuel system control strategy and is executed by the PCM.

The PCM commands a duty cycle to the fuel pump driver module (FPDM).

The FPDM modulates the voltage to the fuel pump (FP) required to achieve the proper fuel pressure. Voltage for the fuel pump is supplied by the power relay or FPDM power supply relay. (For additional information on FPDM operation, refer to FUEL PUMP and FUEL PUMP MONITOR (FPM).)

The fuel rail pressure (FRP) sensor provides the PCM with the current fuel rail pressure. The PCM uses this information to vary the duty cycle output to the FPDM to compensate for varying loads.

The fuel rail temperature (FRT) sensor measures the current fuel temperatures in the fuel rail. This information is used to vary the fuel pressure and avoid fuel system vaporization.

The fuel injector is a solenoid-operated valve that meters the fuel flow to each combustion cylinder. The fuel injector is opened and closed a constant number of times per crankshaft revolution. The amount of fuel is controlled by the length of time the fuel injector is held open. The injector is normally closed and is operated by 12-volt VPWR from the power relay. The ground signal is controlled by the PCM.

A pressure test point valve (Schrader valve) is located on the fuel rail and is used to measure the fuel injector supply pressure for diagnostic procedures and repairs. On vehicles not equipped with a Schrader valve, use the Rotunda Fuel Pressure Test Kit #134-R0087 or equivalent.

There are 3 filtering or screening devices in the fuel delivery system. The intake sock is a fine, nylon mesh screen mounted on the intake side of the fuel pump. There is a fuel filter screen located at the fuel rail side of the fuel injector. The fuel filter assembly is located between the fuel pump and the pressure test point/Schrader valve.

The fuel pump (FP) module is a device that contains the fuel pump and the fuel sender assembly. The fuel pump is located inside the reservoir and supplies fuel through the fuel pump module manifold to the engine and the fuel pump module jet pump.

The inertia fuel shut-off (IFS) switch is used to de-energize the fuel delivery secondary circuit in the event of a collision. The IFS switch is a safety device that should only be reset after a thorough inspection of the vehicle following a collision.

Fig. 67: Fuel System - Electronic Returnless

Fig. 68: Electronic Returnless Fuel System Schematic Diagram

Friday, September 17th, 2010 AT 3:30 AM