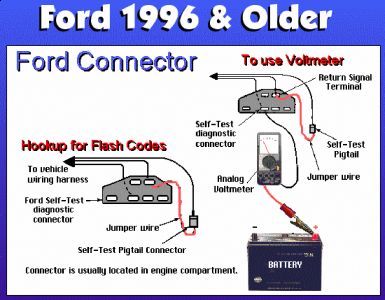

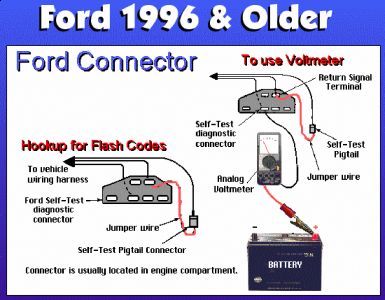

Havent found it, but to reset the PCM ground the STI under the hood on the left fender apron, when the check engine light starts flashing the codes, remove the jumper wire, theis clears the codes from memory.

Also this:Programmable Speedometer/Odometer Module (PSOM) The PSOM receives input from rear brake anti-lock sensor, which is mounted on rear axle differential housing. Vehicle speed (mph) signal is output to PCM. PSOM failure may cause harsh engagements, firm shift feel and abnormal shift schedule. Unexpected downshifts may occur at closed throttle and abnormal TCC operation or engages at WOT. Transmission Control Indicator Light (TCIL) may flash. These RABS valces were notorious, check it for signal across the terminals with dvom set on ac volts, and spin the wheels, you should get a/c volts, the faster you spin, the higher the voltage. Also measure ohms at the sensor, should be 800-1400 ohms.

Diagnostic Aids Code 33 is generated by interrupted sensor signal or radio interference. The following conditions may be cause of problem: � � � Poor connections at rear wheel sensor. � � � Poor contact at ECU connector. � � � Open or shorted rear sensor coil. � � � Open or shorted circuit No. 518 (Light Green/Red). � � � Open or shorted circuit No. 519 (Light Green/Black). � � � Incorrect air gap. � � � Defective rear speed sensor. 1. Code 33: Check Rear Sensor Turn ignition off. Install Breakout Box. Measure resistance between pins No. 21 and 22. If resistance is not 800-1400 ohms, go to next step. If resistance is 800-1400 ohms, go to step 7). 2. Disconnect rear sensor wiring harness connector. Measure resistance between sensor terminals. If resistance is not 800-1400 ohms, replace sensor. If resistance is 800-1400 ohms, go to next step. 3. Check Circuit No. 518 Continuity Turn ignition off. Measure resistance between pin No. 22 and wheel sensor wiring harness connector Light Green/Red wire terminal. If resistance is not about zero ohms, repair circuit No. 518 (Light Green/Red). If resistance is about zero ohms, circuit is okay, go to step 4). 4. Check Circuit No. 519 Continuity Turn ignition off. Measure resistance between pin No. 21 and wheel sensor wiring harness connector Light Green/Black wire terminal. If resistance is not about zero ohms, repair circuit No. 519 (Light Green/Black). If resistance is about zero ohms, go to next step. 5. Check Circuit No. 518 Short To Ground Turn ignition off. Leave rear sensor wiring harness connector disconnected. Measure resistance between pins No. 1 and 22 at Breakout Box. If continuity is present, repair circuit No. 518 (Light Green/Red) short to ground. If continuity is not present, go to next step. 6. Check Circuit No. 519 Short To Ground NOTE: On some models, circuit No. 523 (Red/Pink) is used instead of circuit No. 518 (Light Green/Red). Turn ignition off. Leave rear sensor wiring harness connector disconnected. Measure resistance between pins No. 1 and 21 at Breakout Box. If continuity is present, repair circuit No. 519 (Light Green/Black) short to ground. If continuity is not present, go to next step. 7. Check Sensor Cable For Damage Inspect sensor cable for damage. Repair or replace as necessary. If cable is okay, problem is intermittent and cannot be located at this time. See INTERMITTENT DIAGNOSIS PROCEDURE.

Sunday, July 26th, 2009 AT 4:43 PM