Information for you.

DESCRIPTION AND OPERATION:

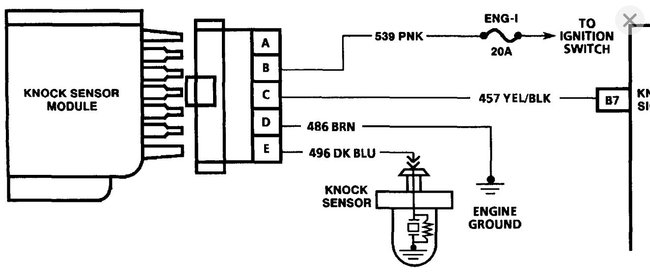

The Knock Sensor (KS) system has a module that sends a voltage signal to the ECM. As the KS detects detonation, the voltage from the KS module to the ECM will drop. This signal allows the ECM to retard timing. The ECM will retard the timing when knock is detected and rpm is above 900 rpm. Diagnostic Trouble Code (DTC) 43 will set when the ECM has detected low voltage at CKT 457 on terminal "B7" for longer than 5 seconds with the engine operating or when the system has failed the functional check. The ECM continually monitors voltage on CKT 457 on terminal "B7."

The ECM will advance the spark timing when:

Engine coolant temperature is above 95°C.

Engine is under heavy load (near WOT).

Test chart

CHART TEST DESCRIPTION

Number(s) below refer to circled number(s) on the diagnostic chart.

1. If a DTC 43 is not set, but a knock signal is indicated while operating at 1500 rpm, listen for an internal engine noise. Under a no load condition there should not be any detonation, if knock is indicated, an internal engine problem may exist.

2. Usually a knock signal can be generated by tapping on the right exhaust manifold. This test can also be performed at idle. Test Number 1 was run at 1500 rpm to determine if a constant knock signal was present, affecting engine performance.

3. This tests whether the knock signal is due to the sensor, a basic engine problem, or the KS module.

4. If the module ground circuit is faulty, the KS module will not function correctly. The test light should light indicating the ground circuit is OK.

5. Contacting CKT 496 with a test light to 12 volts should generate a knock signal to determine whether the knock sensor is faulty, or the KS module can't recognize a knock signal.

DIAGNOSTIC AIDS

Scan tools may be used to diagnose the KS system. The knock signal can be monitored to see if the knock sensor is detecting a knock condition and if the KS module is functioning, knock signal should display "YES, " whenever detonation is present. The ECM can retard the timing up to 20 degrees.

If the KS system checks OK, but detonation is the complaint, refer to Diagnosis By Symptom / Detonation, Spark Knock See: Computers and Control Systems > Symptom Related Diagnostic Procedures > Detonation/Spark Knock/Pings

Thursday, May 3rd, 2018 AT 2:21 PM