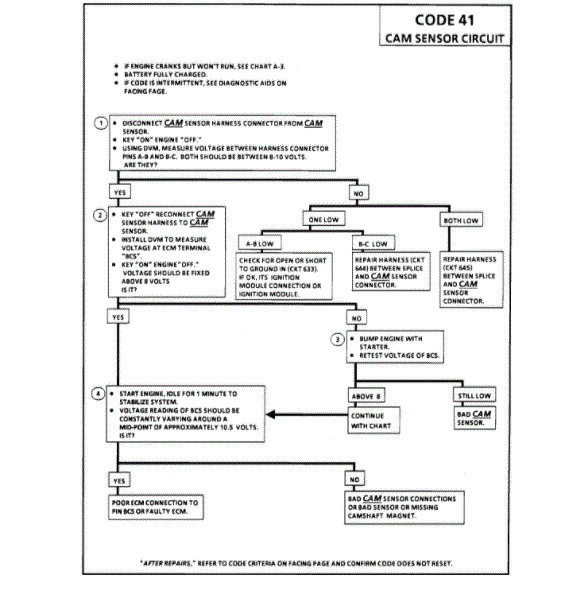

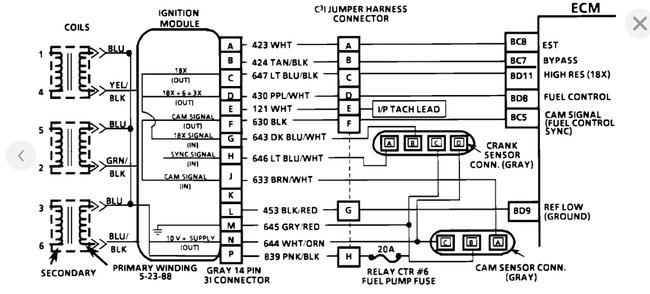

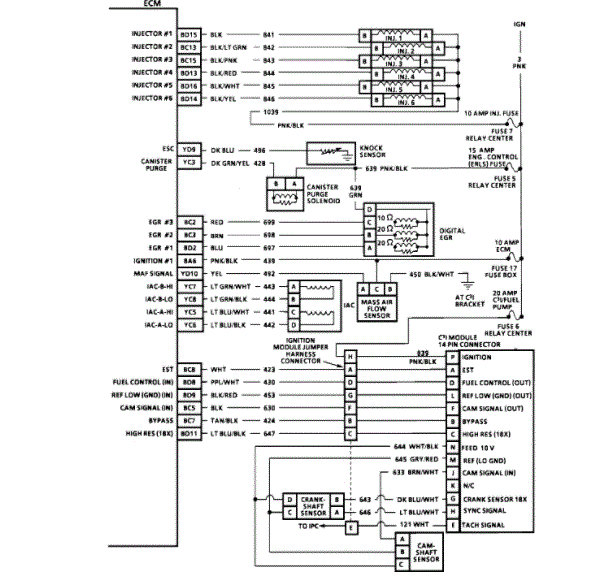

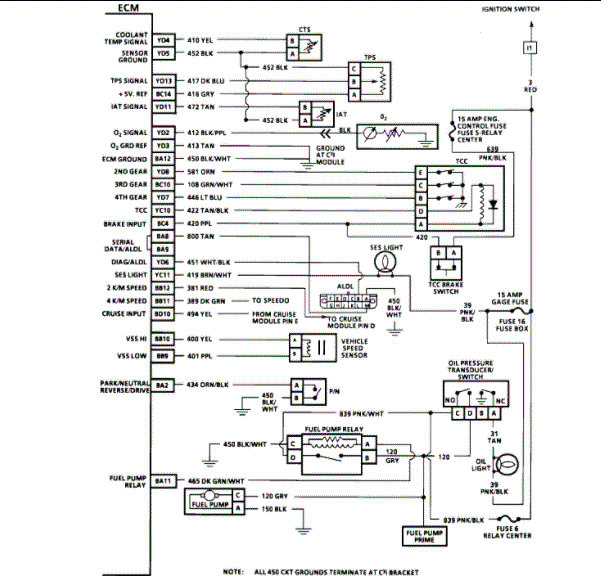

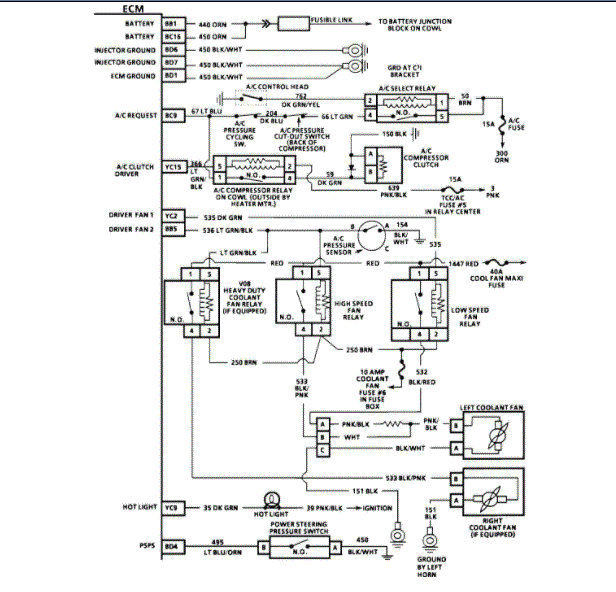

I attached the flow chart and wiring diagram for you of the system for the code 41.

Is the ABS light on by any chance?

You are welcome.

Roy

CIRCUIT DESCRIPTION:

During cranking, the ignition module monitors the dual crank sensor sync signal. The sync signal is used to determine the correct cylinder pair to spark first. After the sync signal has been processed by the ignition module it sends a fuel control reference pulse to the ECM. When the ECM receives this pulse it will command all six injectors to open for a (priming) shot of fuel in all cylinders. After the priming, the injectors are left "OFF" for the next six fuel control reference pulses (two crankshaft revolutions) from the ignition module. This allows each cylinder a chance to use the fuel from the (priming) shot. During this waiting period, a cam pulse will have been received by the ECM. Now the ECM begins to operate the injectors sequentially, based on true camshaft position. However, if the cam signal is not present at start-up a code 41 will be set and the ECM will start sequential fuel delivery in any old random pattern. The engine has a 1 in 6 chance that fuel delivery is correct.

Code 41 sets when the following conditions are met:

Engine is running.

Cam sensor signal not received by by the ECM in last 2 seconds.

NOTE: Because of all the possible color code combinations used on electrical wiring diagrams, always refer to ECM CONNECTOR IDENTIFICATION under ELECTRICAL AND ELECTRONIC WIRING DIAGRAMS for correct color code identification of circuit.

TEST DESCRIPTION: Numbers below refer to circled numbers on the diagnostic chart.

1. This step verifies proper operation of CKTs 633, 644, and 645.

2. Step validates the integrity of CKT 630 from C3I module to ECM.

3. If the camshaft gear magnet is interfacing with the cam sensor the voltage reading will be zero, bumping engine will cause the condition to go away.

4. If the voltage reading of "BC5" is constantly varying and connection to terminal "BC5" are good, the ECM is faulty.

DIAGNOSTIC AIDS:

An intermittent may be caused by a poor connection, rubbed through wire insulation or a wire broken inside the insulation.

Check For:

Poor Connection or a damaged Harness inspect ECM harness connectors for backed out terminal "BC5, " improper mating, broken locks, improperly formed or damaged terminals, poor terminal to wire connection and damaged harness.

Intermittent Test If connections and harness check okay, monitor a digital voltmeter connected from ECM terminal "BC5" to ground while moving related connectors and wiring harness. If the failure is induced, the voltage reading will change. This may help to isolate the location of the malfunction.

Images (Click to make bigger)

Sunday, August 16th, 2020 AT 7:51 AM