Did you remove it from the engine and take it in for testing that way? That is the worst way to identify this type of problem. These generators take a good five horsepower to run wide-open for a few seconds. The better in-store test benches only have one-horsepower motors, so there is no way to do the most important test. That is the full-load output current test.

The 14.7 volts is perfect, but as I mentioned, you could have done that part yourself, and it only means it's okay to do the rest of the tests.

Most professional testers only read ripple voltage on a relative bar chart from "low" to "high". A few that can make printouts do read to a voltage, like yours shows, but few of us know what "normal" is. The clinker here is ripple voltage goes up as output current goes up, and it must be measured during that full-load test. The motor in the test bench I used in my classroom was a one horsepower motor. That would always be stalled out when trying to run an older 65-amp GM generator. At best we could dial them up to produce around 40 amps. To check for the full 65 amps, they had to be run by the car engine.

The smallest generator listed for your vehicle is a 100-amp unit. The most common one is a 105-amp, and there are some optional ones that develop as much as 124 amps. No in-store test bench is going to be able to measure the full-load output current to verify all the diodes are good. It's very possible your generator is okay, but if it isn't, we're going to waste a lot of time looking for some other cause of these problems.

Be aware too there is no such thing as a "weak" generator other than those with a bad diode. That means if the full-load output current test shows 40 amps, you either have a good 40-amp generator or a 120-amp generator with one bad diode. There's no such thing any more as a little 40-amp generator, so we would know 40 amps is not acceptable. If the full-load test shows close to 100 amps or higher, the diodes are okay. Don't get excited if your only develops 90 amps. That is due to production tolerances, and is perfectly fine.

Also, test benches only run generators at just above idle speed where they are the least efficient. To operate, all generators need a coil of wire, a magnet, (electromagnet, in this case), and most importantly, movement between them. That's why the belt has to spin the magnet. That speed of rotation is directly proportional to how much current each generator can develop, and it is why during the full-load output current test, engine speed must be increased to 2,000 rpm. Due to the pulley sizes, the generator spins about four times faster than crankshaft speed to keep it in the more efficient range more often. In-store test benches use a smaller pulley on the drive motor to prevent it from being stalled out, but then it can't get the generator's speed up to the hard-working efficient range.

If the full-load output current test comes up with at least close to 100 amps, look next at the battery. As they age they can allow these generators' voltage spikes to interfere with computer sensor signals resulting in elusive engine performance problems that defy diagnosis. One way to identify those is to unplug the small plug on the back / side of the generator, then observe if the symptoms change. One symptom that seems to be the most common is cylinder misfires clear up.

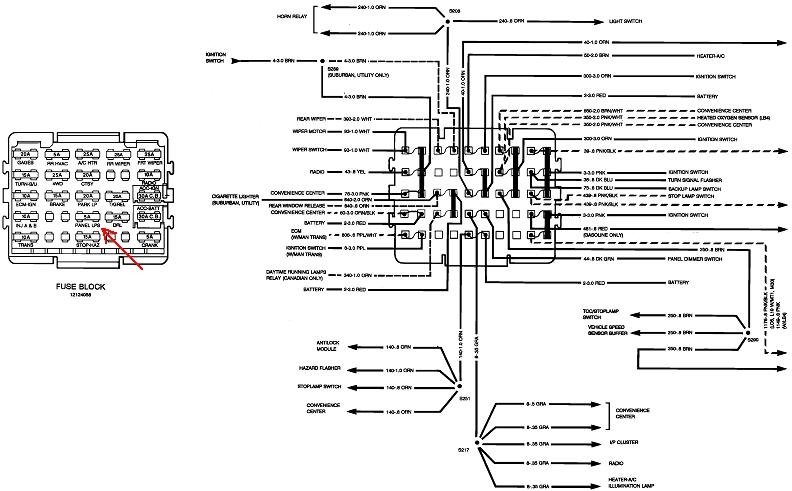

Everything you described are exactly the types of things we see with charging system problems, but while I'm thinking of it, also look for a trailer wiring harness that is chewed up. This is real common on minivans when owners coil them around the trailer hitch. They sit lower to the ground so the wires often rub on the ground, become frayed, then short together. Besides blowing fuses, if a brake / signal wire shorts to the tail light wire, that can back-feed to the head light switch and from there to the dash lights. The radio always has a connection to the both circuits. The tail light circuit tells the display to dim, and the dash light circuit tells it how much to dim. That can cause flickering radio back-lighting and digital display when the brakes are applied. The dash lights will also turn on when the brakes are applied.

Thursday, March 14th, 2019 AT 6:14 PM