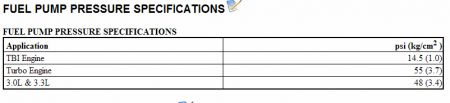

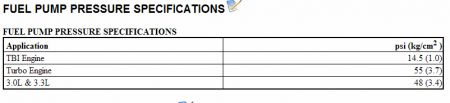

I show a fuel pressure of 14 psi for non turbo 4 cyl, turbo and six cyl are higher, what engine size? Turbo?

TBI FUEL PUMP TEST Release fuel pressure. See FUEL PRESSURE RELEASE in this article. Disconnect 5/16" fuel supply hose. Connect fuel system pressure Gauge (C-4799-A) between fuel supply hose and engine fuel line. 1. Turn ignition on. Using DRB-II (C-4805), activate fuel pump. See FUEL PUMP PRESSURE SPECIFICATIONS table in this article. If fuel pump pressure is at specification, fuel system is functioning properly. 2. If fuel pressure is not to specification, record pressure. Install fuel pressure gauge in fuel supply line at rear of vehicle between fuel tank and fuel filter. 3. Using DRB-II, activate fuel pump. See FUEL PUMP PRESSURE SPECIFICATIONS table in this article. Record pressure reading. If fuel pressure is 5 psi (.4 kg/cm 2 ) higher than first pressure reading, replace fuel filter. 4. If no change in pressure reading is observed, gently squeeze fuel return hose. If fuel pressure increases, replace fuel pressure regulator. If no change in fuel pressure is observed, problem is plugged fuel pump filter sock or defective fuel pump. 5. If fuel pressure is more than specification, remove fuel return hose at rear of vehicle. Connect an extension hose to return hose. Place hose in an approved container with at least a 2 gallon capacity. 6. Using DRB-II, activate fuel pump. If fuel pressure is now within specification, check in-tank return fuel hose for kinking. Replace fuel tank assembly if in-tank reservoir check valve or aspirator jet is plugged. 7. If fuel pressure is still more than specification, remove fuel return hose from throttle body. Connect a substitute hose to throttle body return nipple. Place other end of hose in an approved container. 8. Using DRB-II, activate fuel pump. If fuel pressure is at specification, check for a restricted fuel return line between throttle body and fuel tank. If no change was observed, replace fuel pressure regulator. 9. NOTE: Perform fuel pump test with fuel tank at least half full. Before disconnecting a fuel line during testing, repeat fuel pressure release procedure. Page 1 of 1 BASIC TESTING -1990 Dodge Omni America 4/27/2009

FOUR CLYINDER:

4-CYLINDER PFI FUEL PUMP TEST Release fuel pressure. See FUEL PRESSURE RELEASE in this article. Remove cap from service valve on fuel rail. Connect fuel system pressure Gauge (C-4799-A) to service valve. 1. Turn ignition on. Using DRB-II, activate fuel pump. See FUEL PUMP PRESSURE SPECIFICATIONS table in this article. If fuel pump pressure is at specification, fuel system is functioning properly. 2. If fuel pressure is not to specification, record pressure and remove gauge. Using DRB-II, activate fuel pump. Ensure no fuel leaks from service valve. Install cap on service valve. 3. If fuel pressure is not to specification, install pressure gauge in fuel supply line between fuel tank and fuel filter at rear of vehicle. Using DRB-II, activate fuel pump. 4. Record pressure reading. If fuel pressure is 5 psi (.4 kg/cm 2 ) higher than first pressure reading, replace fuel filter. If no change in pressure reading is observed, gently squeeze fuel return hose. 5. If fuel pressure increases, replace fuel pressure regulator. If no change in fuel pressure is observed, problem is plugged fuel pump filter sock or defective fuel pump. 6. If fuel pressure is more than specification, remove fuel return hose at rear of vehicle. Connect an extension hose to return hose. Place hose in an approved container with at least a 2 gallon capacity. 7. Using DRB-II, activate fuel pump. If fuel pressure is now within specification, check in-tank return fuel hose for kinking. Replace fuel tank assembly if in-tank reservoir check valve or aspirator jet is plugged. 8. If fuel pressure is still more than specification, remove fuel return hose from pressure regulator. Connect a substitute hose to fuel pressure regulator. Place other end of hose in an approved container. 9. Using DRB-II, activate fuel pump. If fuel pressure is at specification, check for a restricted fuel return line. If no change was observed, replace fuel pressure regulator. 10. NOTE: Perform fuel pump test with fuel tank at least half full. Before disconnecting a fuel line during testing, repeat fuel pressure release procedure. Page 1 of 1 BASIC TESTING -1990 Dodge Omni America 4/27/2009

Monday, April 27th, 2009 AT 3:34 PM